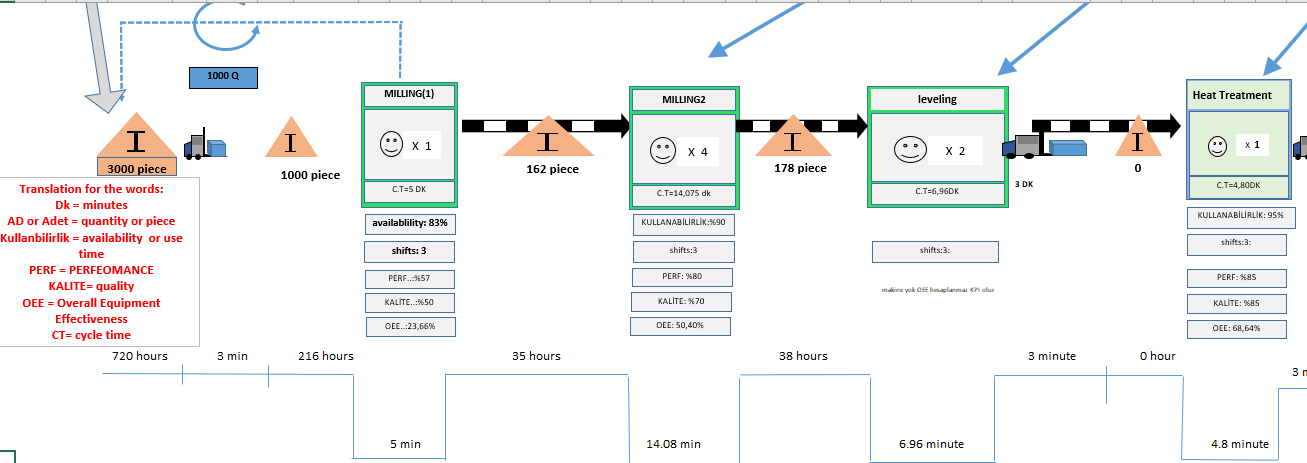

Question: here are 12 operations as shown in the table, and all the numbers are shown also from the current state map part. please solve the

here are 12 operations as shown in the table, and all the numbers are shown also from the current state map part.

please solve the bottleneck problem and the excess inventory problem and give a solution and estimate improvements, ( using lean manufacturing tools and methods).

draw the future state map for it. if you zoom the picture you can see the map clearly.

| Operation | CT (min) | CO | Shifts | performance | Availability | Quality | OEE |

| 1- Milling | 5 | 3 | 57.00% | 83.00% | 50.00% | 23.66% | |

| 2- Milling 2 | 14.08 | 3 | 80.00% | 90.00% | 70.00% | 50.40% | |

| 3- Leveling | 6.96 | 3 | |||||

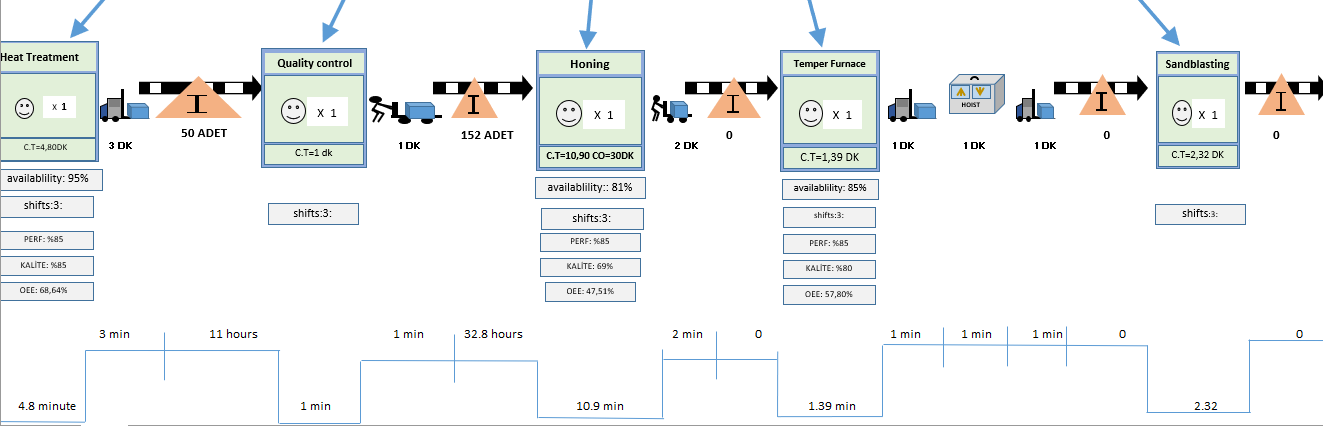

| 4- Heat Treatment | 4.8 | 3 | 85.00% | 95.00% | 85.00% | 68.64% | |

| 5- Quality Control | 1 | 3 | |||||

| 6- Honing | 10.9 | 30 min | 3 | 85.00% | 81.00% | 69.00% | 47.50% |

| 7- Temper Furnace | 1.39 | 3 | 85.00% | 85.00% | 80.00% | 57.80% | |

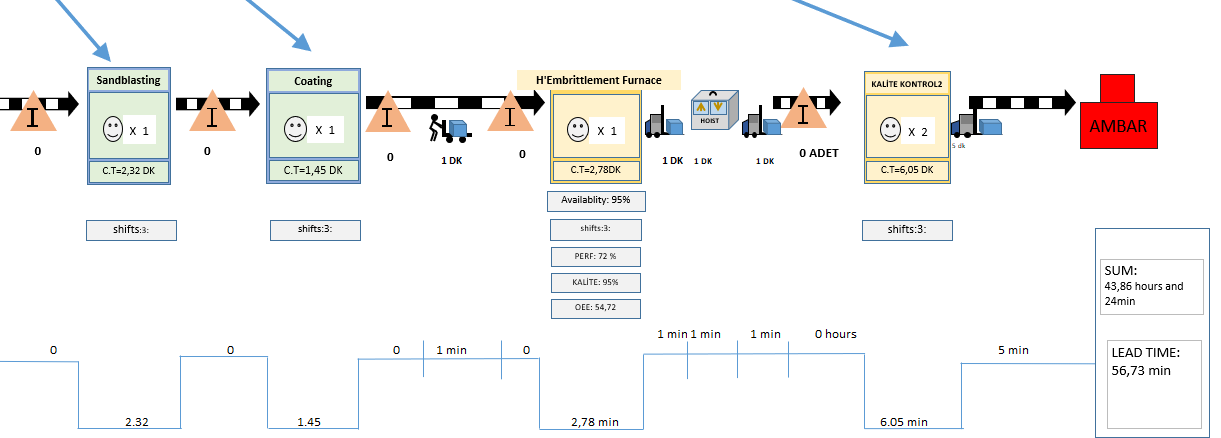

| 8- Sandblasting | 2.32 | 3 | |||||

| 9- Coating | 1.45 | 3 | |||||

| 10- 'H'Embrittlement Furnace | 2.78 | 3 | 72.00% | 95.00% | 95.00% | 54.72% | |

| 11- Quality Control 2 | 6.05 | 3 | |||||

| 12- Delivery to Warehouse | 5 | 3 |

raw material supplier: Aluminium supplier.

Monthly: 3000 ordered per month

Shift: 3

The material is shipped to the company every 3 months.

Main Industry Work Plan:

- 27 working days a month.

- All production units work 3 shifts.

- Each shift is 8 hours.

There are two 15-minute breaks in the shifts and one 30-minute meal break.

Production Processes:

-Operations are written

- Those who are ready for shipment are shipped to the customer on a monthly basis.

- Raw material supply comes in 3-month periods.

Production Planning:

- Production planning department can receive orders from the customer in annual and monthly periods. After the relevant orders are added to the sales order screen, the production planning department receives the data on the sales order screen.

-By looking at the weekly capacity-load report, it is divided into weekly production numbers and MRP is run. Material orders are made based on the current stock levels in MRP. Work orders are given to production based on the customer order quantity.

- The required raw material order is sent to the purchasing department by opening a supply order from the ERP system. Supply orders are opened by looking at the lead times of the relevant stock code.

(Lead time times are calculated by looking at procurement time, purchase time, and input inspection time.)

- Orders finalized to the raw material supplier company on a monthly basis; The order form is sent to the supplier with the order form according to technical drawing. In this way, deadlines are agreed upon.

- A 1-month security stock is kept for reasons such as design errors, planning errors, production errors (waste, scrap).

The seven wastes in Lean are;

Transportation, Inventory, Motion, Waiting, Overproduction, Overprocessing and Defects

We need to eliminate these wastes.

Milling1 produces 252 parts per day, milling 2 with four machines 458 parts per day, leveling 362 parts per day, heat treatment 262 parts per day, quality control 1 produces 1260 parts per day. Normally, the company should produce 111 parts according to their order plans, but these operations produce much more, making overstock. In the honing operation, 115 pieces were produced per day, that is, there is a bottleneck. The bottleneck refers to the slowest process in production. Therefore, the speed of production depends on the bottleneck process. Therefore, improvements should be made especially in the Honing operation.

the end of the processes

SUM: 43,86 hours and 24min, lead time: 56,73 min

part1 of the map

part 2:

part 3:

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts