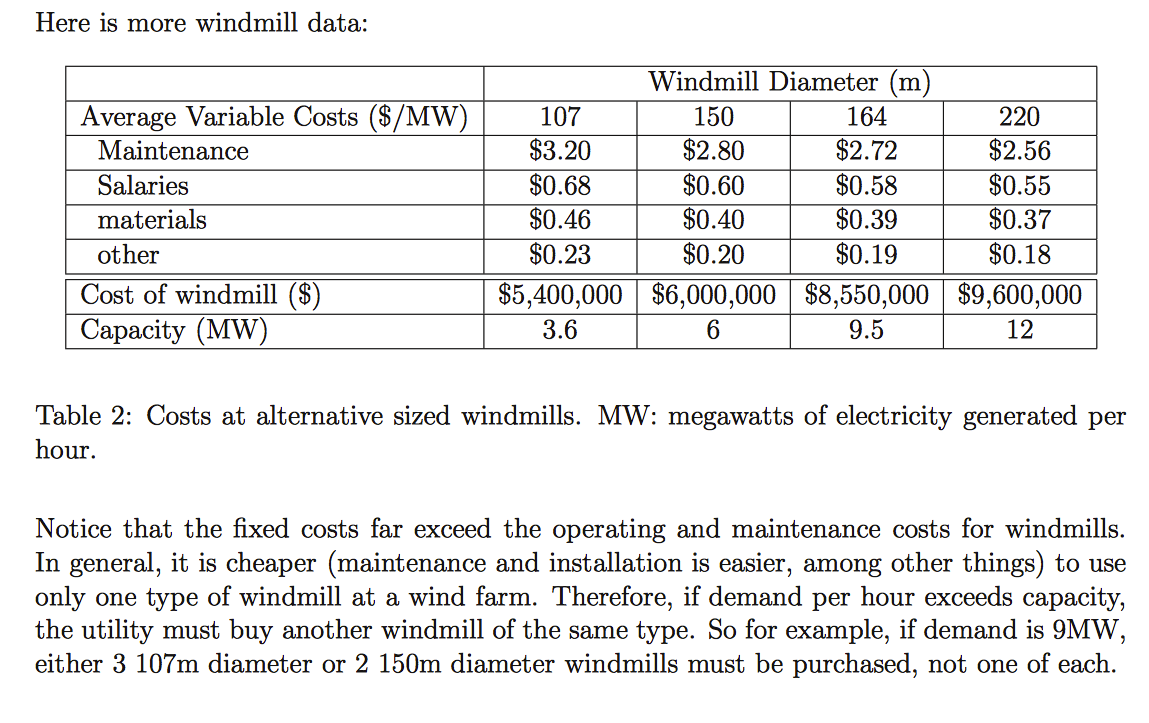

Question: Here is more windmill data: Average Variable Costs ($/MW) Maintenance Salaries materials other Cost of windmill ($) Capacity (MW) Windmill Diameter (m) 107 150 164

Here is more windmill data: Average Variable Costs ($/MW) Maintenance Salaries materials other Cost of windmill ($) Capacity (MW) Windmill Diameter (m) 107 150 164 220 $3.20 $2.80 $2.72 $2.56 $0.68 $0.60 $0.58 $0.55 $0.46 $0.40 $0.39 $0.37 $0.23 $0.20 $0.19 $0.18 $5,400,000 $6,000,000 $8,550,000 $9,600,000 3.6 6 9.5 12 Table 2: Costs at alternative sized windmills. MW: megawatts of electricity generated per hour. Notice that the fixed costs far exceed the operating and maintenance costs for windmills. In general, it is cheaper (maintenance and installation is easier, among other things) to use only one type of windmill at a wind farm. Therefore, if demand per hour exceeds capacity, the utility must buy another windmill of the same type. So for example, if demand is 9MW, either 3 107m diameter or 2 150m diameter windmills must be purchased, not one of each. a. Calculate the average total costs if anticipated demand is 4,6,...,24 MW, for all 4 types of windmills (Excel is helpful here). b. Find the points on the LRAC curve for production levels of 4,6,..., 24 MW. That is, determine what type of windmill should be built for each production level and then report the average cost given that type of windmill is built. c. Suppose one 164m and one 220m windmills were purchased (recall in parts a and b we did not mix types of windmills, but here suppose we did) anticipating demand of 21.5 MW. However, demand fell short and was only 8MW. How many MW should each windmill generate? d. Are long run average costs always decreasing as production increases from 14 to 24 MW? Explain

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts