Question: Here is the question and the key answer however I need calculations 5. An operations manager wants to determine the optimal lot size to ensure

Here is the question and the key answer however I need calculations

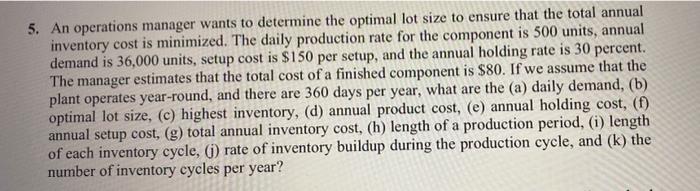

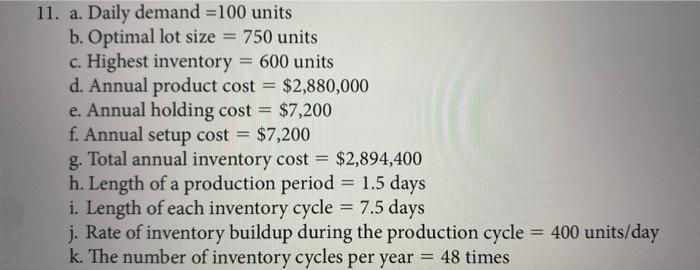

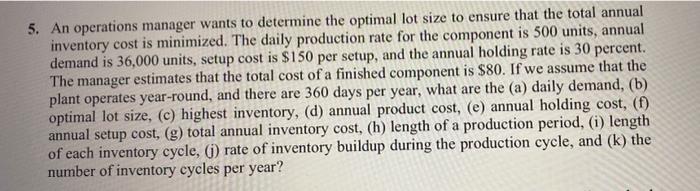

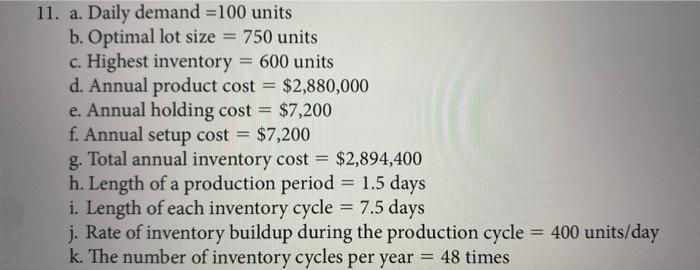

5. An operations manager wants to determine the optimal lot size to ensure that the total annual inventory cost is minimized. The daily production rate for the component is 500 units, annual demand is 36,000 units, setup cost is $150 per setup, and the annual holding rate is 30 percent. The manager estimates that the total cost of a finished component is $80. If we assume that the plant operates year-round, and there are 360 days per year, what are the (a) daily demand, (b) optimal lot size, (c) highest inventory, (d) annual product cost, (e) annual holding cost, (f) annual setup cost, (g) total annual inventory cost, (h) length of a production period, (i) length of each inventory cycle, (i) rate of inventory buildup during the production cycle, and (k) the number of inventory cycles per year? 11. a. Daily demand =100 units b. Optimal lot size = 750 units c. Highest inventory = 600 units d. Annual product cost = $2,880,000 e. Annual holding cost $7,200 f. Annual setup cost $7,200 g g. Total annual inventory cost = $2,894,400 h. Length of a production period = 1.5 days i. Length of each inventory cycle = 7.5 days j. Rate of inventory buildup during the production cycle = 400 units/day k. The number of inventory cycles per year = 48 times

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock