Question: Hi, I need help with question d. Please help QUESTION 3 Grinding is one of the most common material removal processes. There are many process

Hi, I need help with question d. Please help

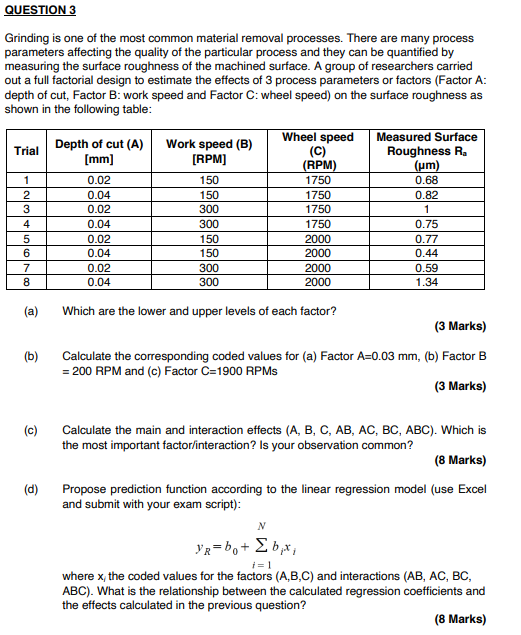

QUESTION 3 Grinding is one of the most common material removal processes. There are many process parameters affecting the quality of the particular process and they can be quantified by measuring the surface roughness of the machined surface. A group of researchers carried out a full factorial design to estimate the effects of 3 process parameters or factors (Factor A: depth of cut, Factor B: work speed and Factor C: wheel speed) on the surface roughness as shown in the following table: Work speed (B) Wheel speed Trial Depth of cut (A) Measured Surface [mm] [RPM] (C) Roughness R. (RPM) (um) 0.02 150 1750 0.68 0.04 150 1750 0.82 0.02 300 1750 1 0.04 300 1750 0.75 0.02 150 2000 0.77 0.04 150 2000 0.44 0.02 300 2000 0.59 8 0.04 300 2000 1.34 (a) Which are the lower and upper levels of each factor? (3 Marks) (b) Calculate the corresponding coded values for (a) Factor A=0.03 mm, (b) Factor B = 200 RPM and (c) Factor C=1900 RPMs (3 Marks) (c) Calculate the main and interaction effects (A, B, C, AB, AC, BC, ABC). Which is the most important factor/interaction? Is your observation common? (8 Marks) (d) Propose prediction function according to the linear regression model (use Excel and submit with your exam script): N VR= bot 2b,x; 1 = 1 where x, the coded values for the factors (A,B,C) and interactions (AB, AC, BC, ABC). What is the relationship between the calculated regression coefficients and the effects calculated in the previous question? (8 Marks)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts