Question: Hi , please help me this work. thanks For this activity, I want you to create a 3 column table of risks you could run

Hi , please help me this work.

thanks

Hi, here they are and thanks for your feedback ..

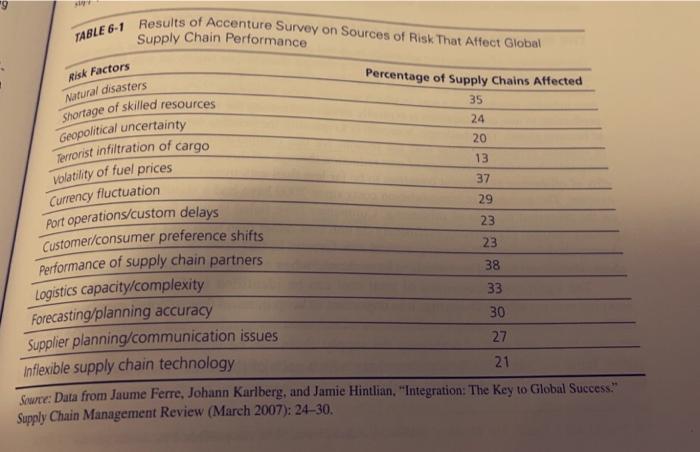

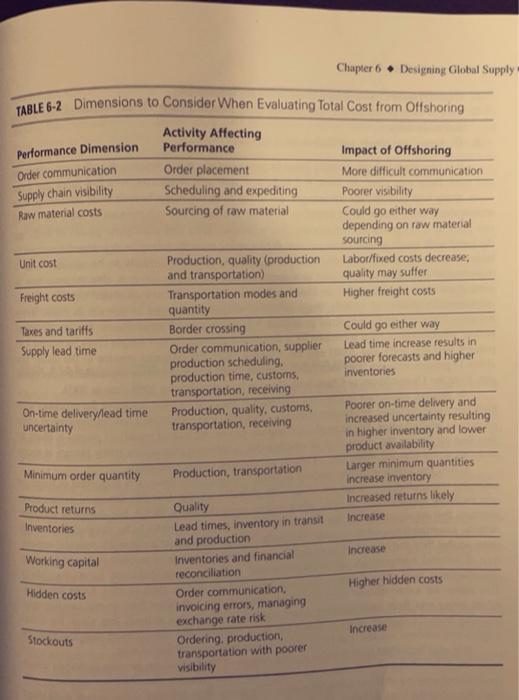

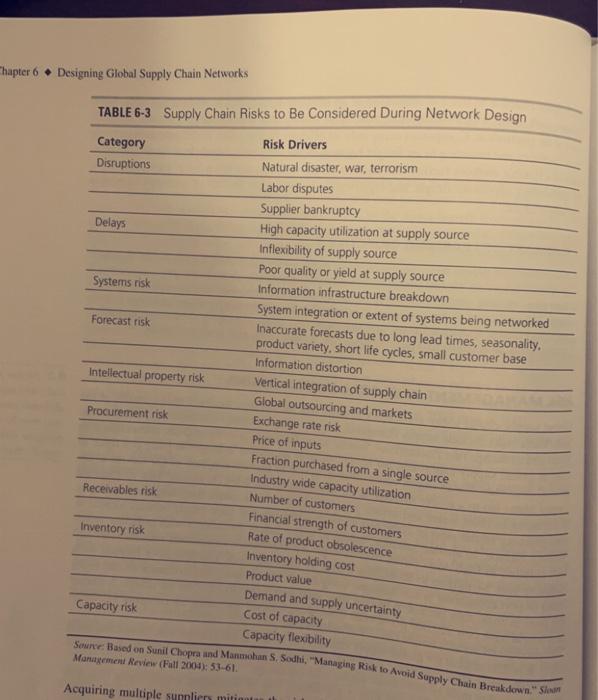

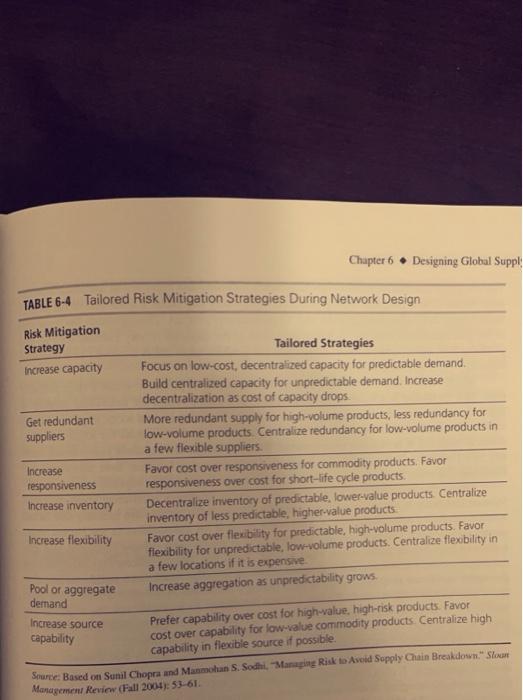

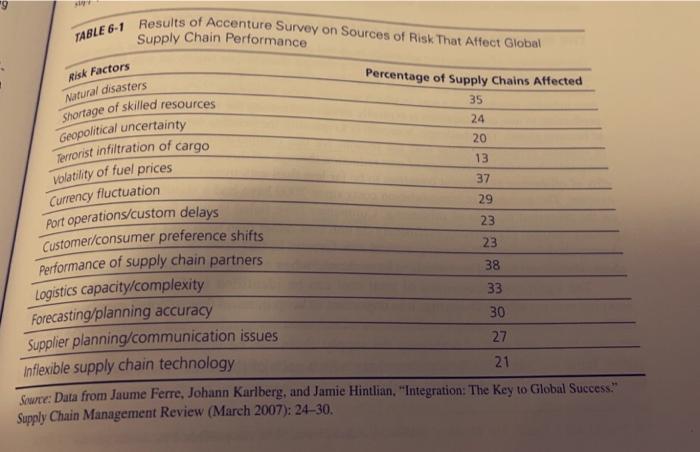

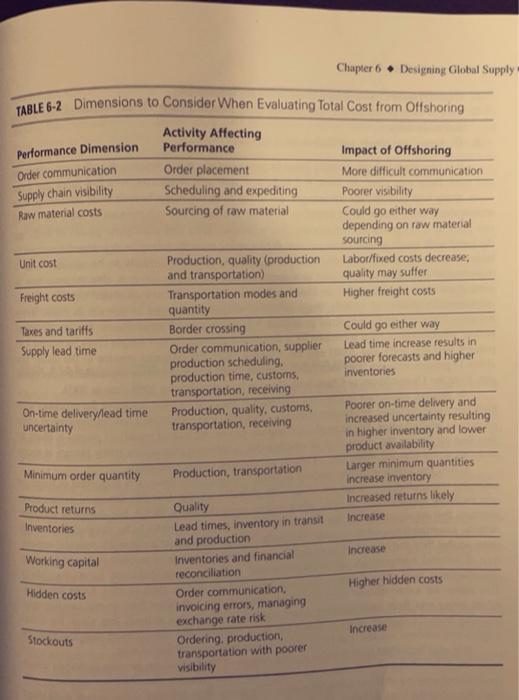

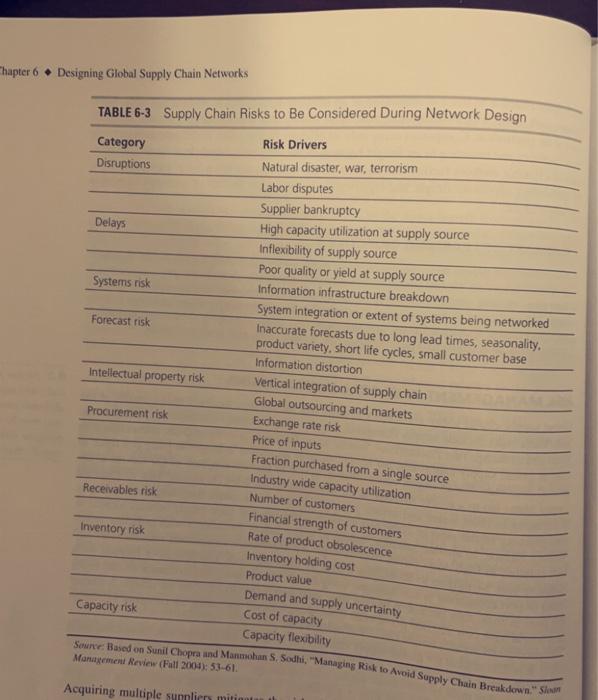

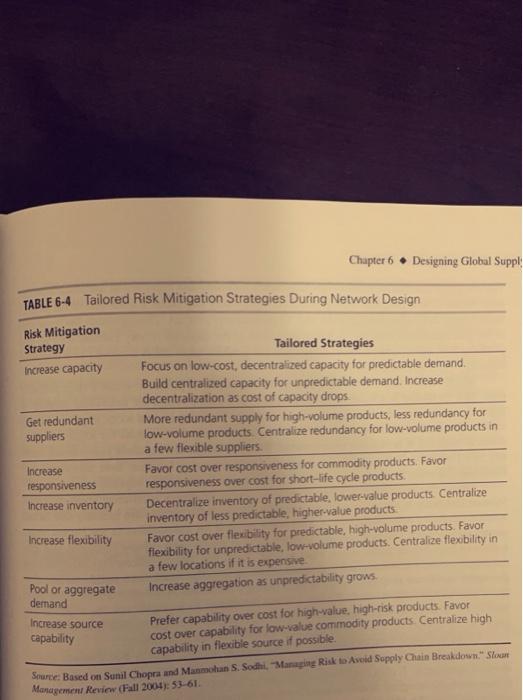

Shortage of skilled resources Terrorist infiltration of cargo TABLE 6-1 Results of Accenture Survey on Sources of Risk That Affect Global Chain Risk Factors Natural disasters Percentage of Supply Chains Affected 35 24 Geopolitical uncertainty 20 13 37 29 Volatility of fuel prices Currency fluctuation Port operations/custom delays Customer/consumer preference shifts Performance of supply chain partners Logistics capacity/complexity Forecasting/planning accuracy Supplier planning/communication issues inflexible supply chain technology Source: Data from Jaume Ferre, Johann Karlberg, and Jamie Hintlian. "Integration: The Key to Global Success." Supply Chain Management Review (March 2007): 2430. 23 23 38 33 30 27 21 Chapter 6 Designing Global Supply TABLE 6-2 Dimensions to consider When Evaluating Total Cost from Offshoring Performance Dimension Order communication Supply chain visibility Raw material costs Activity Affecting Performance Order placement Scheduling and expediting Sourcing of raw material Impact of Offshoring More difficult communication Poorer visibility Could go either way depending on raw material sourcing Labor/fixed costs decrease, quality may suffer Higher freight costs Unit cost Freight costs Taxes and tariffs Supply lead time Production, quality (production and transportation) Transportation modes and quantity Border crossing Order communication, supplier production scheduling. production time, customs, transportation, receiving Production, quality, customs, transportation, receiving Could go either way Lead time increase results in poorer forecasts and higher inventories On-time delivery/lead time uncertainty Poorer on-time delivery and increased uncertainty resulting in higher inventory and lower product availability Larger minimum quantities increase inventory Increased returns likely Increase Minimum order quantity Production, transportation Product returns Inventories Increase Working capital Quality Lead times, inventory in transit and production Inventories and financial reconciliation Order communication invoicing errors, managing exchange rate risk Ordering, production, transportation with poorer visibility Higher hidden costs Hidden costs Increase Stockouts Son Based on Sunil Chopra and Manmohan S. Sodhi. "Managing Risk to Avoid Supply Chain Breakdown. So Chapter 6 Designing Global Supply Chain Networks TABLE 6-3 Supply Chain Risks to Be Considered During Network Design Category Disruptions Delays Systems risk Risk Drivers Natural disaster, war, terrorism Labor disputes Supplier bankruptcy High capacity utilization at supply source Inflexibility of supply source Poor quality or yield at supply source Information infrastructure breakdown System integration or extent of systems being networked Inaccurate forecasts due to long lead times, seasonality. product variety short life cycles, small customer base Information distortion Vertical integration of supply chain Global outsourcing and markets Exchange rate risk Forecast risk Intellectual property risk Procurement risk Receivables risk Inventory risk Price of inputs Fraction purchased from a single source Industry wide capacity utilization Number of customers Financial strength of customers Rate of product obsolescence Inventory holding cost Product value Demand and supply uncertainty Cost of capacity Capacity flexibility Capacity risk Management Review (Fall 2004): 53-61. Acquiring multiple sunnic mitin Chapter 6 Designing Global Suppl TABLE 6-4 Tailored Risk Mitigation Strategies During Network Design Risk Mitigation Strategy Increase capacity Get redundant suppliers Increase responsiveness Increase inventory Tailored Strategies Focus on low-cost, decentralized capacity for predictable demand. Build centralized capacity for unpredictable demand. Increase decentralization as cost of capacity drops More redundant supply for high-volume products, less redundancy for low-volume products. Centralize redundancy for low-volume products in a few flexible suppliers Favor cost over responsiveness for commodity products. Favor responsiveness over cost for short-life cycle products Decentralize inventory of predictable, lower-value products Centralize inventory of less predictable, higher-value products Favor cost over flexibility for predictable, high-volume products. Favor flexibility for unpredictable, low-volume products. Centralize flexibility in a few locations if it is expensive Increase aggregation as unpredictability grows. Increase flexibility Pool or aggregate demand Increase source capability Prefer capability over cost for high-value, high-risk products. Favor cost over capability for low-value commodity products. Centralize high capability in flexible source if possible. Source: Based on Sunil Chopra und Manmohan S. Sodhi. Managing Risk to Avoid Supply Chain Breakdown." Sloan Management Review (Fall 2004): 53-61

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock