Question: HONOLULU ASSEMBLY PLANT THROUGHPUT CASE STUDY This is the first day on the job for you as the resident throughput expert of the Honolulu Assembly

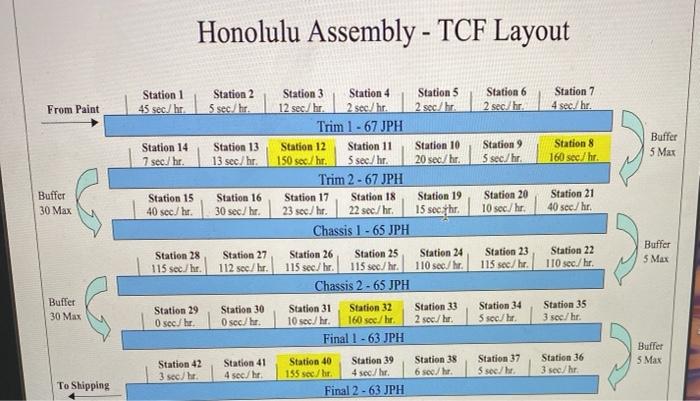

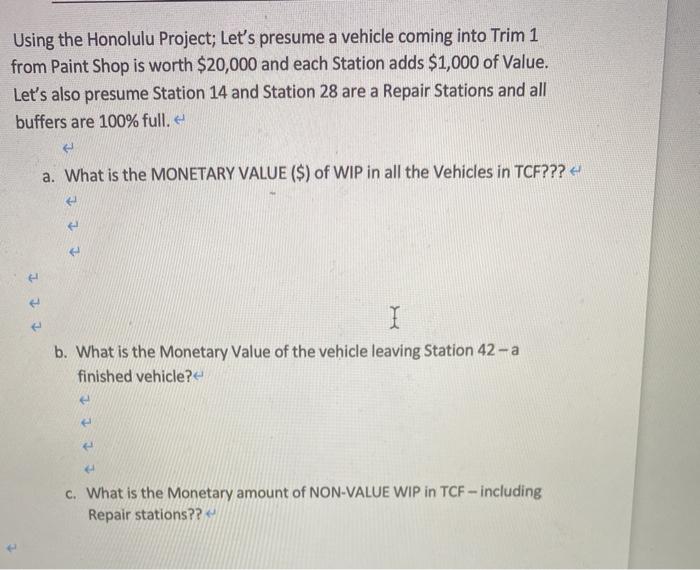

HONOLULU ASSEMBLY PLANT THROUGHPUT CASE STUDY This is the first day on the job for you as the resident throughput expert of the Honolulu Assembly Plant. What's been happening in the plant requires your immediate attention. At the Honolulu Assembly Plant, the cars are being built at full line speed, but downtime issues are preventing on-time deliveries to customers. This condition has been further aggravated because of increasing sales of the product and a growing backlog of orders, which is currently at 68 days. The situation is expected to continue due to the excellent styling, superior engineering design, excellent quality, and competitive pricing of the product. Unfortunately, delays are creating customer complaints, and unless the conditions improve, we will lose some of our customers. There is also increasing pressure from headquarters to eliminate this problem, or personnel changes could take place in the next few months. Overtime hours and Saturday production is at peak levels. Any additional production time is no longer an option. A line speed change has been considered, however, there are several facility restrictions in Trim, Chassis, Final (TCF). The plant is scheduled to build 960 units in a 16-hour day. So far, the plant has been running at 1.1 hours of unscheduled overtime a shift. Body Shop is averaging 56.1 SAJPH, Paint is averaging 56.5, while Assembly is averaging 50.7. The buffers between the 3 Centers are 30 Units maximum and 7 units minimum. Based on data, personnel from Body, Paint, and TCF determine that TCF is the bottleneck. You scheduled a meeting with TCF personnel and found that a Throughput Problem Solving Team was formed a couple of weeks ago. The team collected and analyzed production data and conducted floor reviews to ensure that the throughput focus would be accurate. In order to understand the process, the team developed a layout and collected average downtime for each station in the last 4 weeks. Based on the downtime data, the Throughput Problem Solving Team has decided to work on the four stations with the highest downtime. A layout of the TCF Departments complete with line speed of each conveyor is attached with this case study. Also attached are the charts showing the SAJPH rates for the 3 centers during the last 4 weeks. In TCF, stations 8, 12, 32 and 40 exhibited the highest amounts of average downtime. Considering the resources and the level of work required to maintain the current production level, the team members believe that the best idea would be to concentrate all their efforts in those 4 stations. The team estimates that we would gain somewhere around 10 more minutes of productive time per hour if we can resolve the downtime problems at the 4 stations Honolulu Assembly - TCF Layout Station 2 Station 1 45 sec.hr Station 6 2 sec./hr Station 7 4 sec.hr From Paint Station 14 7 sec./hr. Station 13 13 sec.hr Station 9 5 sec./hr Station 8 160 sec/hr Buffer 5 Max Buffer 30 Max Station 15 40 sec/hr. Station 16 30 sec hr. Station 20 10 sec.hr Station 21 40 sec./hr. Station 3 Station 4 Stations 12 sec.hr 2 sec/hr 2 sec.hr Trim 1 - 67 JPH Station 12 Station 11 Station 10 150 sec./hr. 5 sec./hr. 20 sec./hr. Trim 2 - 67 JPH Station 17 Station 18 Station 19 23 sec/hr. 22 sec/hr. 15 sec.hr Chassis 1 - 65 JPH Station 26 Station 25 Station 24 115 sec/hr. 115 sec/hr. 110 sec./hr. Chassis 2 - 65 JPH Station 31 Station 32 Station 33 10 sec./hr. 160 sec/hr 2 sec/ht. Final 1 - 63 JPH Station 40 Station 39 Station 38 155 sec/br. 4 sec./hr. 6 sc/hr. Final 2 - 63 JPH Station 28 115 sec./hr. Station 27 112 sec/hr. Station 23 115 sec/hr. Station 22 110 sec./hr. Buffer 5 Max Buffer 30 Max Station 29 O sec/hr Station 30 Osce.hr Station 34 5 sec/br. Station 35 3 sec/hr. Station 42 3 sec/ Buffer 5 Max Station 41 4 sec./hr. Station 37 5 sec/hr. Station 36 3 sec./hr. To Shipping Using the Honolulu Project; Let's presume a vehicle coming into Trim 1 from Paint Shop is worth $20,000 and each Station adds $1,000 of Value. Let's also presume Station 14 and Station 28 are a Repair Stations and all buffers are 100% full. a. What is the MONETARY VALUE ($) of WIP in all the Vehicles in TCF??? 4 I b. What is the Monetary Value of the vehicle leaving Station 42-a finished vehicle? c. What is the Monetary amount of NON-VALUE WIP in TCF - including Repair stations?? HONOLULU ASSEMBLY PLANT THROUGHPUT CASE STUDY This is the first day on the job for you as the resident throughput expert of the Honolulu Assembly Plant. What's been happening in the plant requires your immediate attention. At the Honolulu Assembly Plant, the cars are being built at full line speed, but downtime issues are preventing on-time deliveries to customers. This condition has been further aggravated because of increasing sales of the product and a growing backlog of orders, which is currently at 68 days. The situation is expected to continue due to the excellent styling, superior engineering design, excellent quality, and competitive pricing of the product. Unfortunately, delays are creating customer complaints, and unless the conditions improve, we will lose some of our customers. There is also increasing pressure from headquarters to eliminate this problem, or personnel changes could take place in the next few months. Overtime hours and Saturday production is at peak levels. Any additional production time is no longer an option. A line speed change has been considered, however, there are several facility restrictions in Trim, Chassis, Final (TCF). The plant is scheduled to build 960 units in a 16-hour day. So far, the plant has been running at 1.1 hours of unscheduled overtime a shift. Body Shop is averaging 56.1 SAJPH, Paint is averaging 56.5, while Assembly is averaging 50.7. The buffers between the 3 Centers are 30 Units maximum and 7 units minimum. Based on data, personnel from Body, Paint, and TCF determine that TCF is the bottleneck. You scheduled a meeting with TCF personnel and found that a Throughput Problem Solving Team was formed a couple of weeks ago. The team collected and analyzed production data and conducted floor reviews to ensure that the throughput focus would be accurate. In order to understand the process, the team developed a layout and collected average downtime for each station in the last 4 weeks. Based on the downtime data, the Throughput Problem Solving Team has decided to work on the four stations with the highest downtime. A layout of the TCF Departments complete with line speed of each conveyor is attached with this case study. Also attached are the charts showing the SAJPH rates for the 3 centers during the last 4 weeks. In TCF, stations 8, 12, 32 and 40 exhibited the highest amounts of average downtime. Considering the resources and the level of work required to maintain the current production level, the team members believe that the best idea would be to concentrate all their efforts in those 4 stations. The team estimates that we would gain somewhere around 10 more minutes of productive time per hour if we can resolve the downtime problems at the 4 stations Honolulu Assembly - TCF Layout Station 2 Station 1 45 sec.hr Station 6 2 sec./hr Station 7 4 sec.hr From Paint Station 14 7 sec./hr. Station 13 13 sec.hr Station 9 5 sec./hr Station 8 160 sec/hr Buffer 5 Max Buffer 30 Max Station 15 40 sec/hr. Station 16 30 sec hr. Station 20 10 sec.hr Station 21 40 sec./hr. Station 3 Station 4 Stations 12 sec.hr 2 sec/hr 2 sec.hr Trim 1 - 67 JPH Station 12 Station 11 Station 10 150 sec./hr. 5 sec./hr. 20 sec./hr. Trim 2 - 67 JPH Station 17 Station 18 Station 19 23 sec/hr. 22 sec/hr. 15 sec.hr Chassis 1 - 65 JPH Station 26 Station 25 Station 24 115 sec/hr. 115 sec/hr. 110 sec./hr. Chassis 2 - 65 JPH Station 31 Station 32 Station 33 10 sec./hr. 160 sec/hr 2 sec/ht. Final 1 - 63 JPH Station 40 Station 39 Station 38 155 sec/br. 4 sec./hr. 6 sc/hr. Final 2 - 63 JPH Station 28 115 sec./hr. Station 27 112 sec/hr. Station 23 115 sec/hr. Station 22 110 sec./hr. Buffer 5 Max Buffer 30 Max Station 29 O sec/hr Station 30 Osce.hr Station 34 5 sec/br. Station 35 3 sec/hr. Station 42 3 sec/ Buffer 5 Max Station 41 4 sec./hr. Station 37 5 sec/hr. Station 36 3 sec./hr. To Shipping Using the Honolulu Project; Let's presume a vehicle coming into Trim 1 from Paint Shop is worth $20,000 and each Station adds $1,000 of Value. Let's also presume Station 14 and Station 28 are a Repair Stations and all buffers are 100% full. a. What is the MONETARY VALUE ($) of WIP in all the Vehicles in TCF??? 4 I b. What is the Monetary Value of the vehicle leaving Station 42-a finished vehicle? c. What is the Monetary amount of NON-VALUE WIP in TCF - including Repair stations

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts