Question: How could this process be improved so as to reduce the amount of waste? PR 27-3B Lean accounting ObL. 2 d In Com-Tel Inc. manufactures

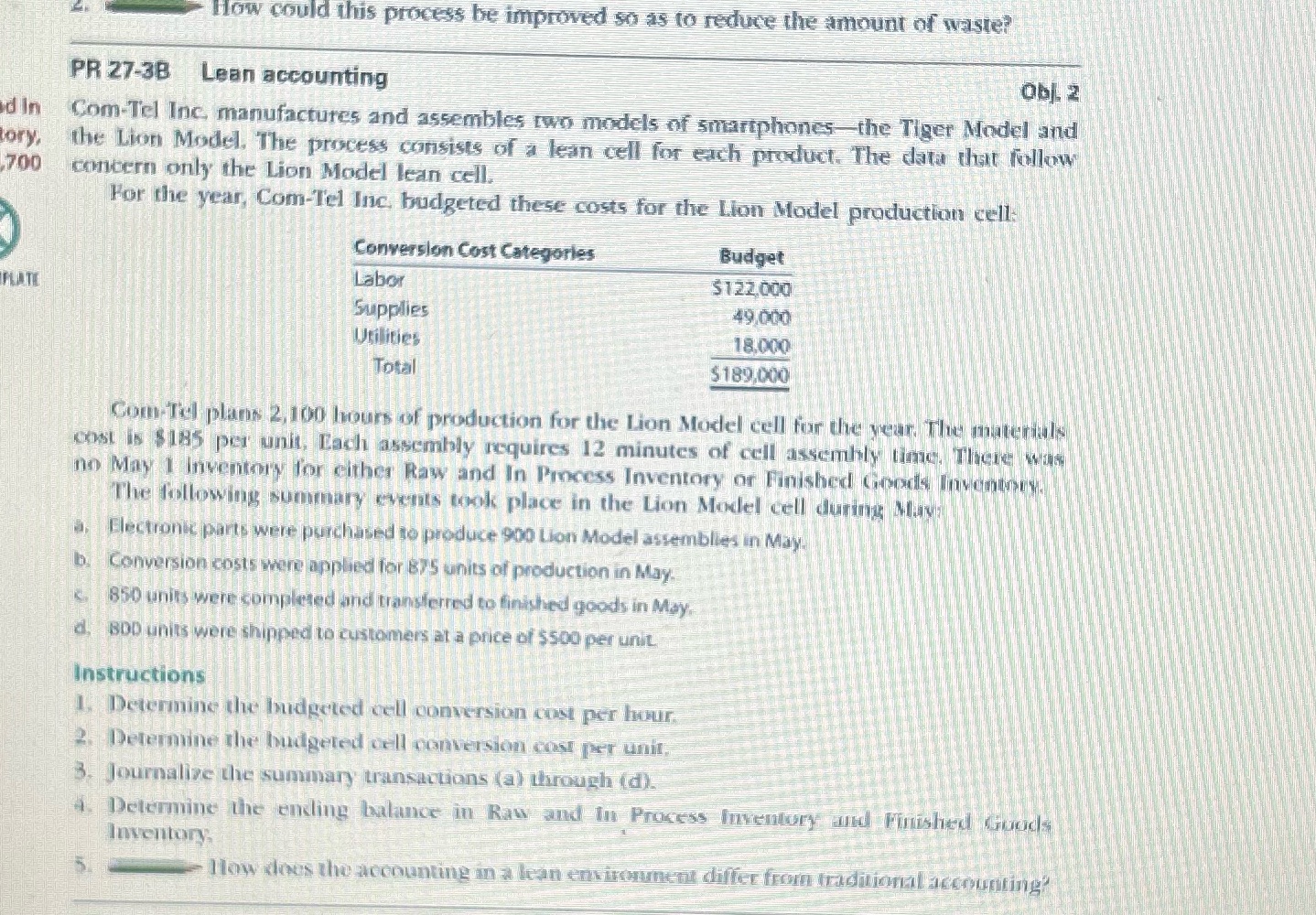

How could this process be improved so as to reduce the amount of waste? PR 27-3B Lean accounting ObL. 2 d In Com-Tel Inc. manufactures and assembles two models of smartphones-the Tiger Model and tory, the Lion Model. The process consists of a lean cell for each product. The data that follow 700 concern only the Lion Model lean cell. For the year, Com-Tel Inc. budgeted these costs for the Lion Model production cell: Conversion Cost Categories Budget PLATE Labor $122.000 Supplies 49.000 Utilities 18,000 Total $189,000 Com-Tel plans 2,100 hours of production for the Lion Model cell for the year. The materials cost is $185 per unit, Each assembly requires 12 minutes of cell assembly time. There was no May I Inventory for either Raw and In Process Inventory or Finished Goods Inventory! The following summary events took place in the Lion Model cell during May Electronic parts were purchased to produce 900 Lion Model assemblies in May. by Conversion costs were applied for 875 units of production in May 850 units were completed and transferred to finished goods in May. BDD units were shipped to customers at a price of $500 per unit Instructions I. Determine the budgeted cell conversion cost per hour 2. Determine the budgeted cell conversion cost per unit 3. Journalize the summary transactions (a) through (d). A. Determine the ending balance in Raw and In Process Inventory and Finished Goods Inventory 5. How does the accounting in a lean environment differ from traditional accounting

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts