Question: How do you do this step-by-step? Analytics Exercise 21-3 (Algo) Recently, Paris, the production control Manager at Brunswick. read an article on time-phased requirement planning.

How do you do this step-by-step?

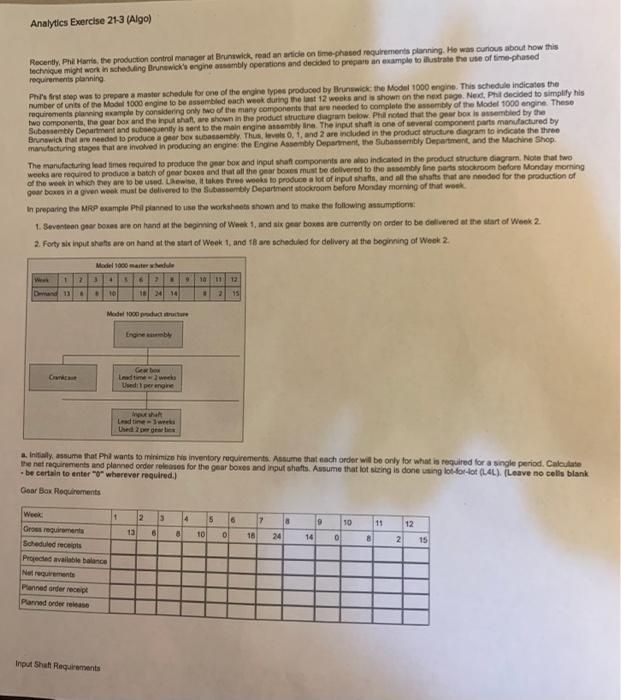

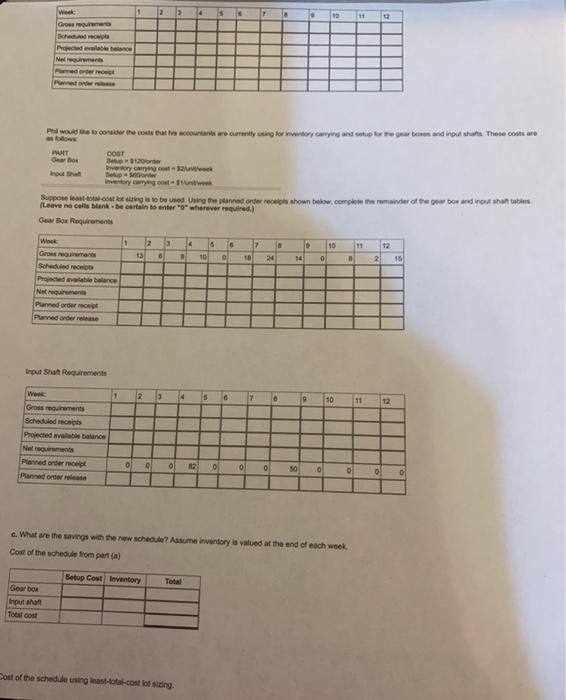

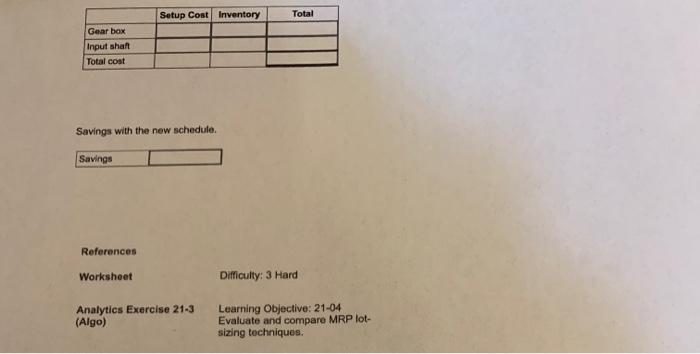

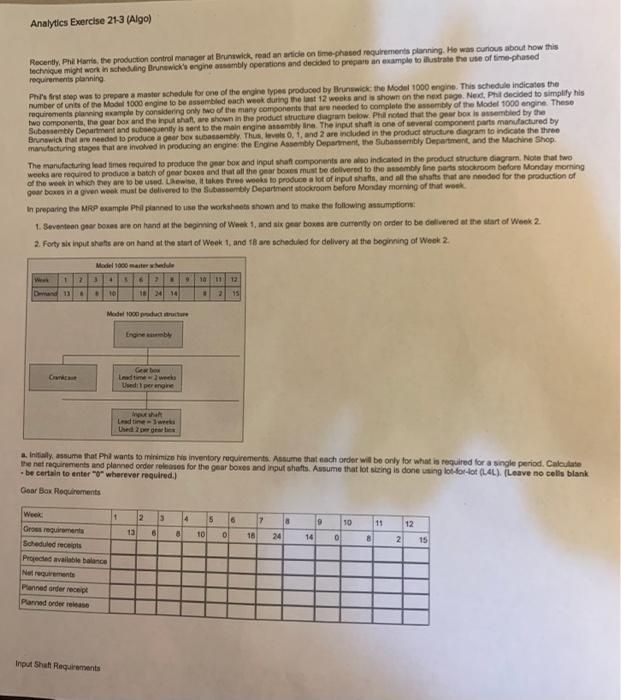

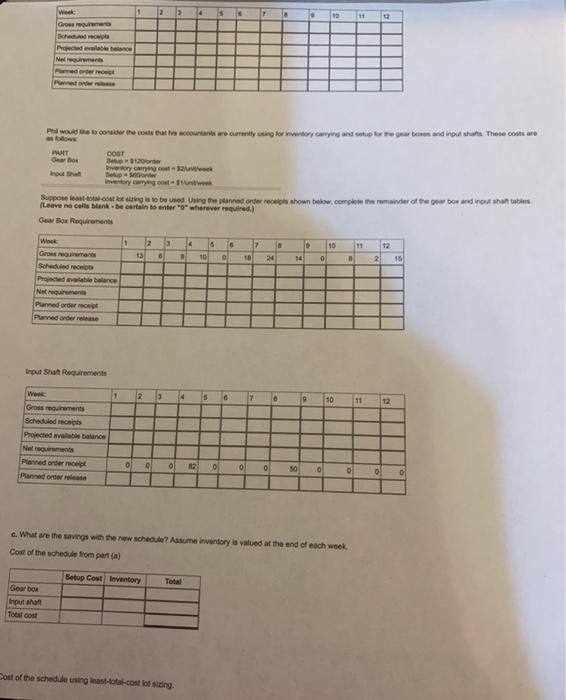

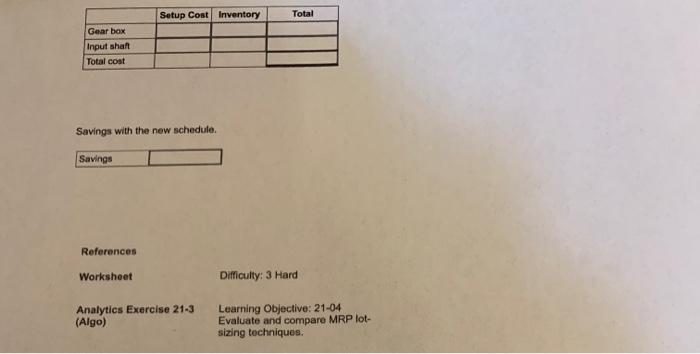

Analytics Exercise 21-3 (Algo) Recently, Paris, the production control Manager at Brunswick. read an article on time-phased requirement planning. He was curious about how this technique might work in scheduling Brunswick's engine ambly operations and decided to prepare an example to llustrate the use of time phased requirement planning Phil's first step was to prepare a master schedule for one of the engine types produced by Brunswick the Model 1000 engine. This schedule indicates the number of unts of the Model 1000 engine to be assembled each week during the last 12 weeks and is shown on the next page. Next Phil decided to simplify his requirements planning example by considering only two of the many components that we needed to complete the assembly of the Model 1000 engine. These two components, the gear box and the input that are shown in the product structure diagram below. Phill noted that the gearbox is assembled by the Subassembly Department and subsequently is sent to the main engine ambay are. The input shaft is one of several component parts manufactured by Brunswick that are needed to produce a gear box subsembly Thus, teves 0, 1 and 2 are included in the product structure diagram to indicate the three manufacturing stages that are involved in producing an engine the Engine Assembly Department, the Subassembly Department and the Machine Shop The manufacturing load times required to produce the gear box and input shaft components are indicated in the product structure diagram. Note that two works are required to produce a batch of gearboxes and that all the gear boxes must be delivered to the embly fine parts stockroom before Monday morning of the week in which they are to be used. Lewis, it takes three weeks to produce a lot of input shafts, and all the shafts that are needed for the production of gourboxes in a given week must be delivered to the Subassembly Department stockroom before Monday morning of the work In preparing the MRP example Phil planned to use the worksheets shown and to make the following assumptions 1. Seventeen paar bows are on hand at the beginning of Work 1, and als gear bome we currently on order to be delivered at the start of Week 2 2. Forty six input shorts are on hand at the start of Week 1, and are scheduled for delivery at the beginning of Wook 2 Model 1000 meter hele 1234 316 10 11 12 Dead 10 1824 14 #2 15 Medel 10 por Lande week Usedil pregre Latine week nuhan Uhed Inily, assume that Phl wants to minimize is inventory requirements. Assume that each order will be only for what is required for a single period. Calculate the net requirements and planned order releases for the gear boxes and input shatte. Assume that it string is done using lo-for-lot (L4L). (Leave no cells blank be certain to enter"0" wherever required.) Gear Box Requirements + 2 3 4 5 7 8 9 10 6 0 11 Week Grossegurament Scheduled rects Projected available balance 12 15 6 TO 18 24 14 0 8 2 15 Panned order receipt Parned order Iro Shut Requirements 1 2 5 14 5 19 11 wie Growers New Groot Panto Prawoken hec at a costants are currently using overtory crying and white carbone and input state. These coure PAT Gearbox COST 12 Spo Surpose festo.coloring is to be used Using the planned order shown below.complete the remainder of the ground out that Leave a call blank.be certain to enter" wherever required) Box Requirements Wik + 3 4 5 6 17 12 13 D 10 6 10 0 24 0 2 15 Scheduled mom Predwabebalance Nel regime Planned and Parved order Input Shaft Requirements 2 3 14 5 6 10 111 12 w 1 Gorurement Scheduled Projected weblanca Nements Planned order Planned onder o ol ol 2 0 0 0 50 0 0 0 0 c. What are the savings with the new schedule? Assume inventory is valued at the end of each week Cost of the schedule from part() Setup Cost Inventory Total Gearbox Input han Toulou out of the schedule using lastea.cost otsing Setup Cost Inventory Total Gear box Input shat Total cost Savings with the new schedule. Savings References Worksheet Difficulty: 3 Hard Analytics Exercise 21-3 (Algo) Learning Objective: 21-04 Evaluate and compare MRP lot- sizing techniques

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock