Question: How much is the relevant unit production costs that should be considered in the decision to schedule the 45,000 hours available machine time in order

How much is the relevant unit production costs that should be considered in the decision to schedule the 45,000 hours available machine time in order to realize the maximum potential cost savings?

13. If the allocation of machine time is based on potential cost savings per machine hour, what is the best combination of parts that should be produced?

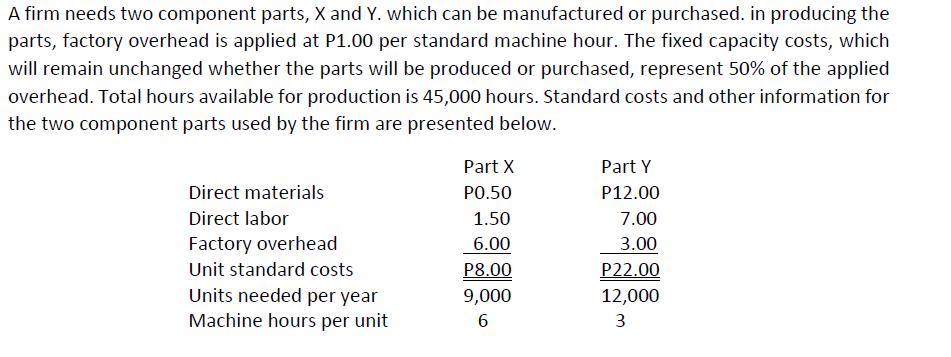

A firm needs two component parts, X and Y. which can be manufactured or purchased. in producing the parts, factory overhead is applied at P1.00 per standard machine hour. The fixed capacity costs, which will remain unchanged whether the parts will be produced or purchased, represent 50% of the applied overhead. Total hours available for production is 45,000 hours. Standard costs and other information for the two component parts used by the firm are presented below. Direct materials Direct labor Factory overhead Unit standard costs Units needed per year Machine hours per unit Part X P0.50 1.50 6.00 P8.00 9,000 6 Part Y P12.00 7.00 3.00 P22.00 12,000 3

Step by Step Solution

3.46 Rating (149 Votes )

There are 3 Steps involved in it

To determine the best combination of parts that should be produced to realize the maximum potential cost savings we need to calculate the relevant uni... View full answer

Get step-by-step solutions from verified subject matter experts