Question: How to solve A solid 5 9 - mm - diameter cold - rolled brass [ G = 3 7 . 6 GPa ] shaft

How to solve

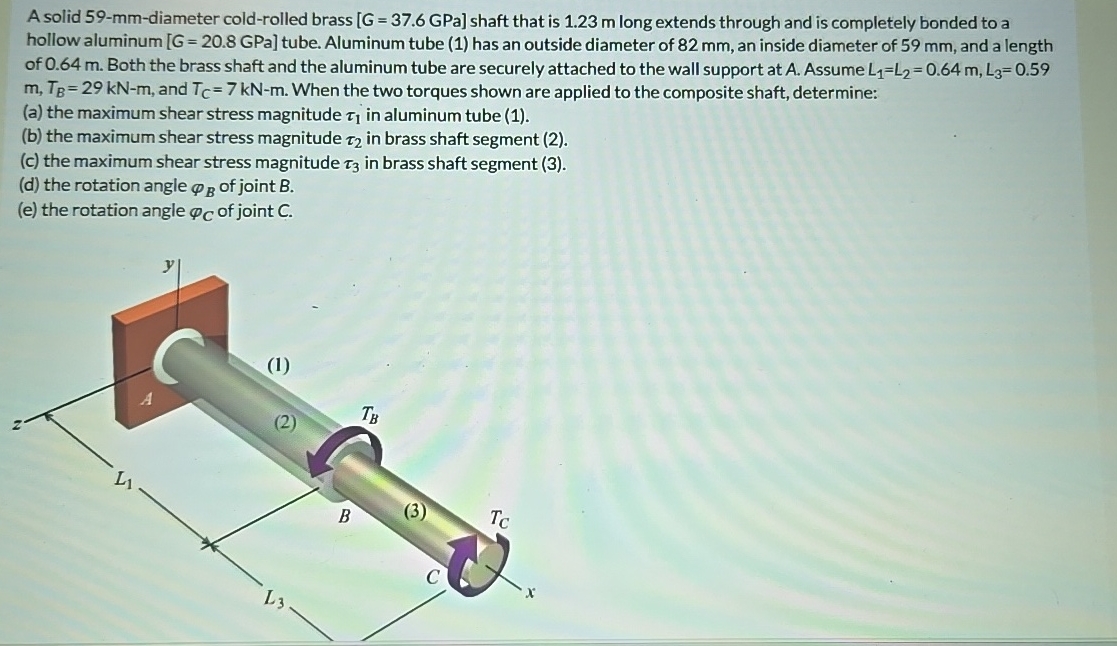

A solid mmdiameter coldrolled brass GPa shaft that is m long extends through and is completely bonded to a

hollow aluminum GPa tube. Aluminum tube has an outside diameter of mm an inside diameter of mm and a length

of m Both the brass shaft and the aluminum tube are securely attached to the wall support at Assume

and When the two torques shown are applied to the composite shaft, determine:

a the maximum shear stress magnitude in aluminum tube

b the maximum shear stress magnitude in brass shaft segment

c the maximum shear stress magnitude in brass shaft segment

d the rotation angle of joint

e the rotation angle of joint

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock