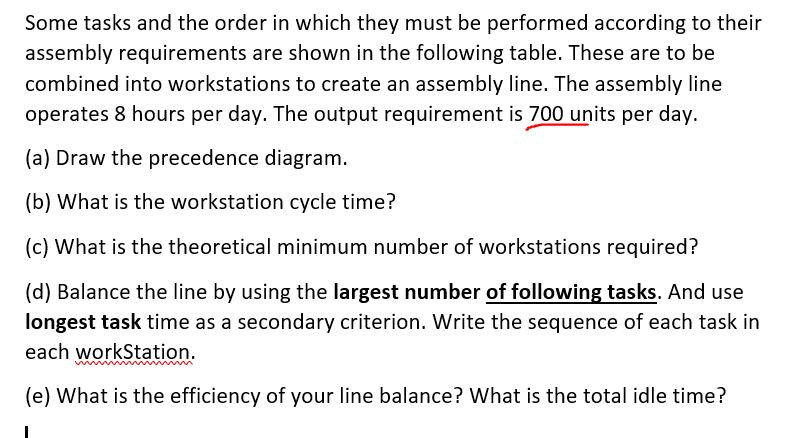

Question: i AM ASKING THIS QUESTION THE 2ND TIME. The last chegg expert did not do it correctly. Please show your work. This time I have

i AM ASKING THIS QUESTION THE 2ND TIME. The last chegg expert did not do it correctly. Please show your work. This time I have even given the formulas below:

Cycle time = Production time per day/ Required output per day

Theoretical minimum # of workstations required = Sum of task times/ Cycle time

efficiency of line balance = total task time/ (# of workstations x cycle time)

total idle time = workstation cycle time x (revised units- actual units)

| Task | Task Time (Seconds) | Immediate Predecessor |

| A | 15 | - |

| B | 24 | A |

| C | 6 | A |

| D | 12 | B |

| E | 18 | B |

| F | 7 | C |

| G | 11 | C |

| H | 9 | D |

| I | 14 | E |

| J | 7 | F, G |

| K | 15 | H, I |

| L | 10 | J, K |

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts