Question: I could really use some help with this Lab. It is the T.O.T.E.S Case Study Lab 2 for Accounting. As much as I would appreciate

I could really use some help with this Lab. It is the T.O.T.E.S Case Study Lab 2 for Accounting. As much as I would appreciate the answers I would also like to learn the process of solving these questions in order to fully understand. Lab 1 is included as it is needed information to finish Lab 2. Thank you!

Thanks again!

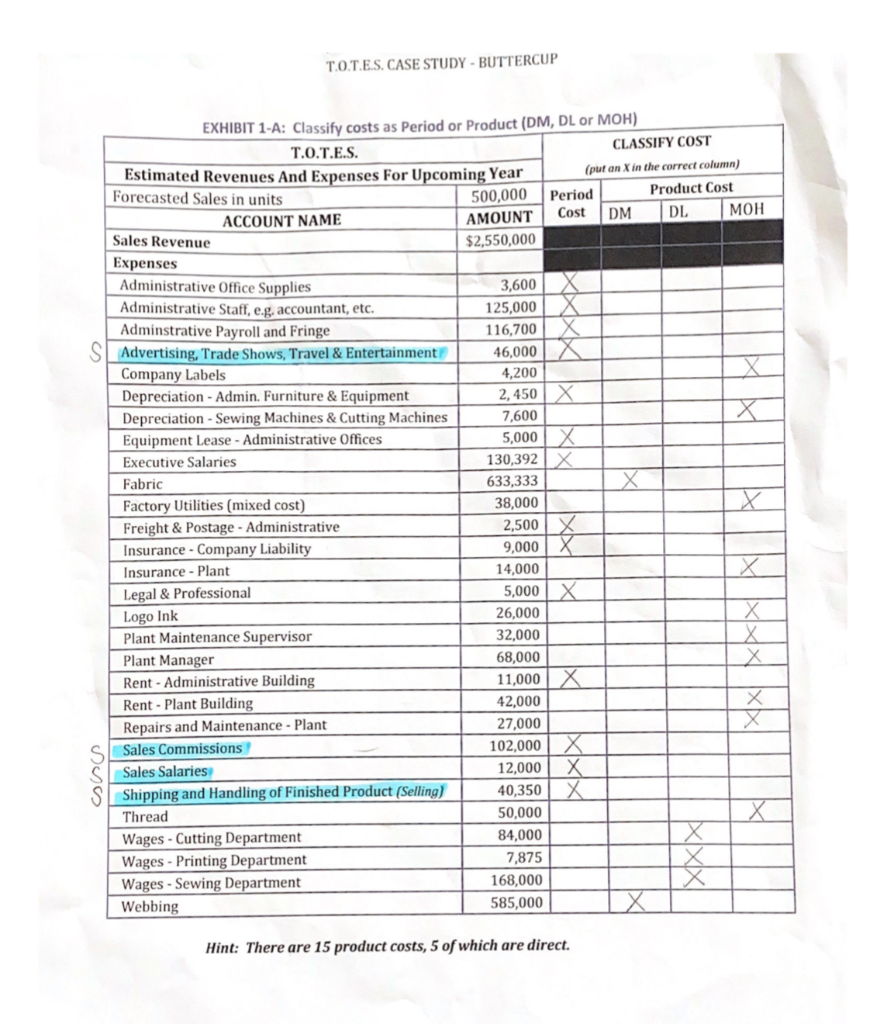

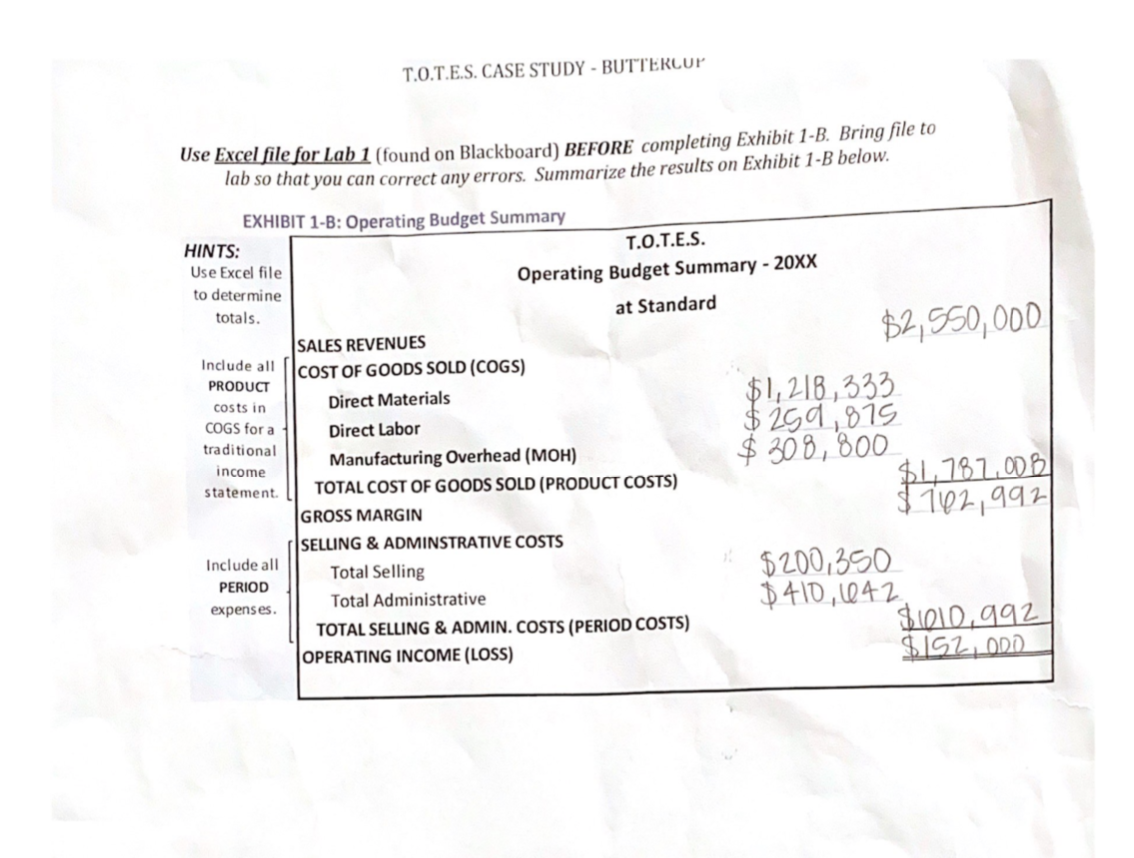

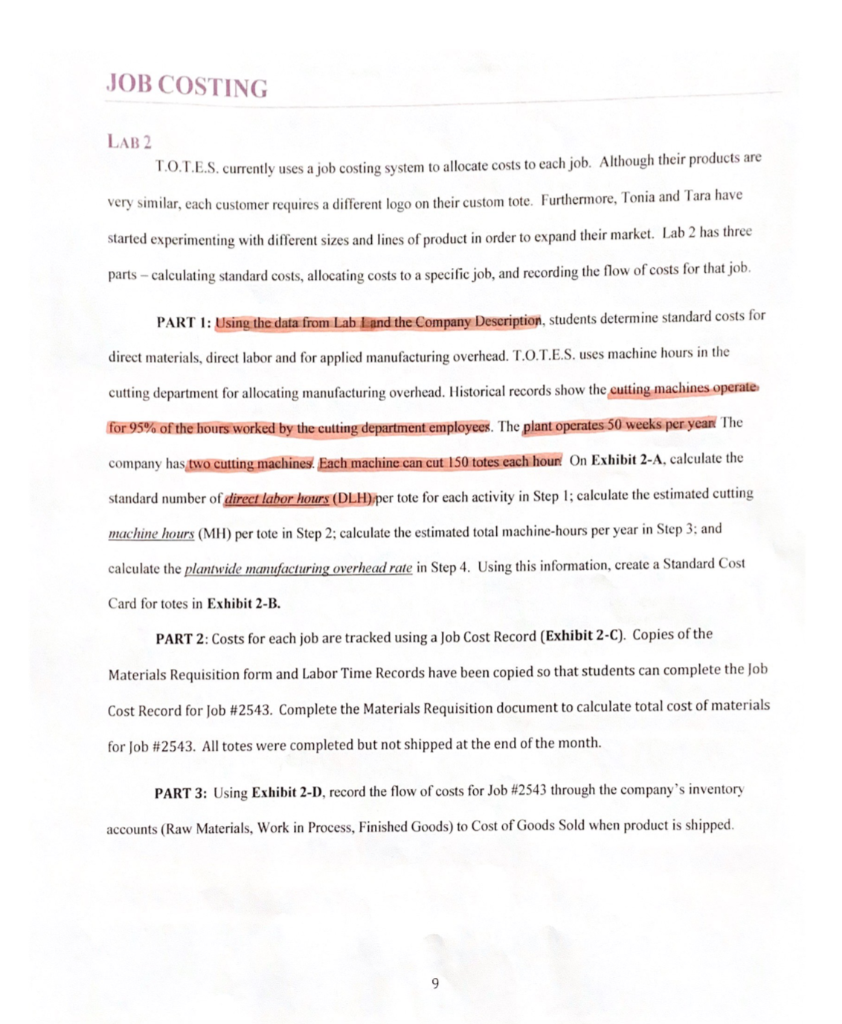

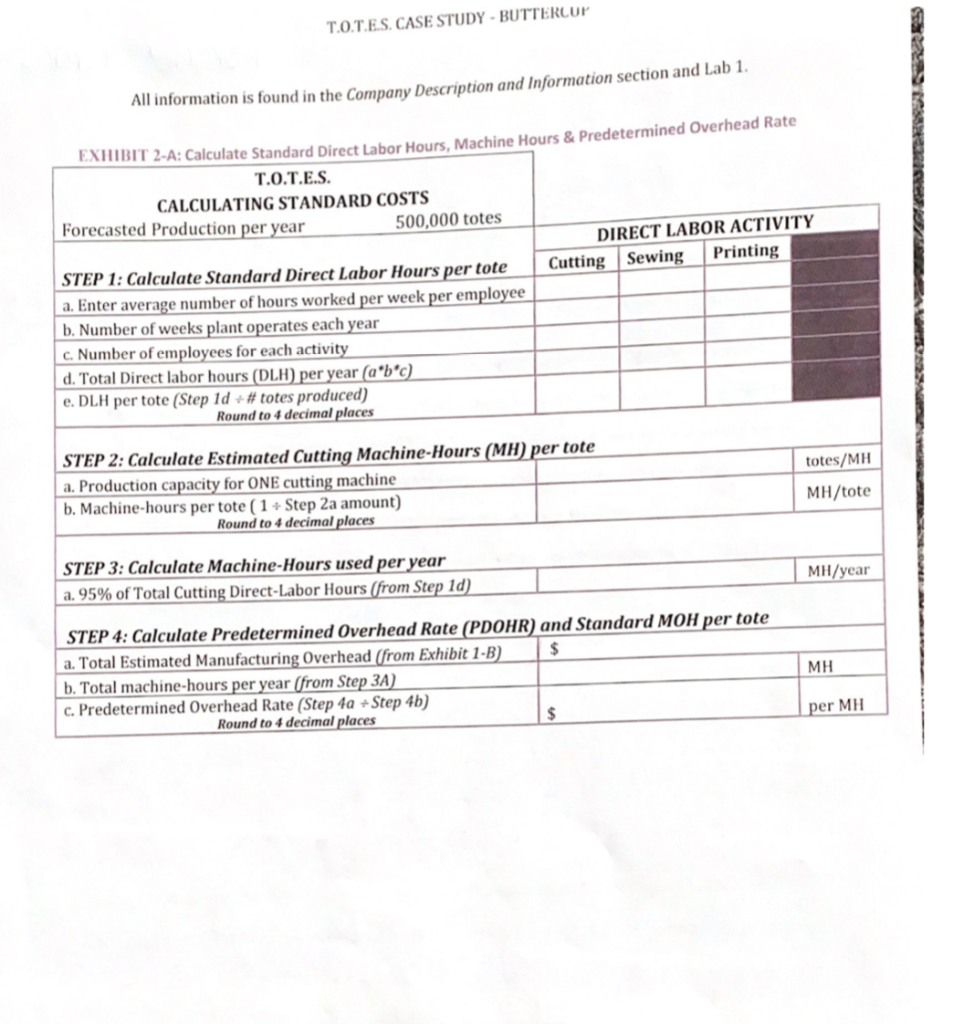

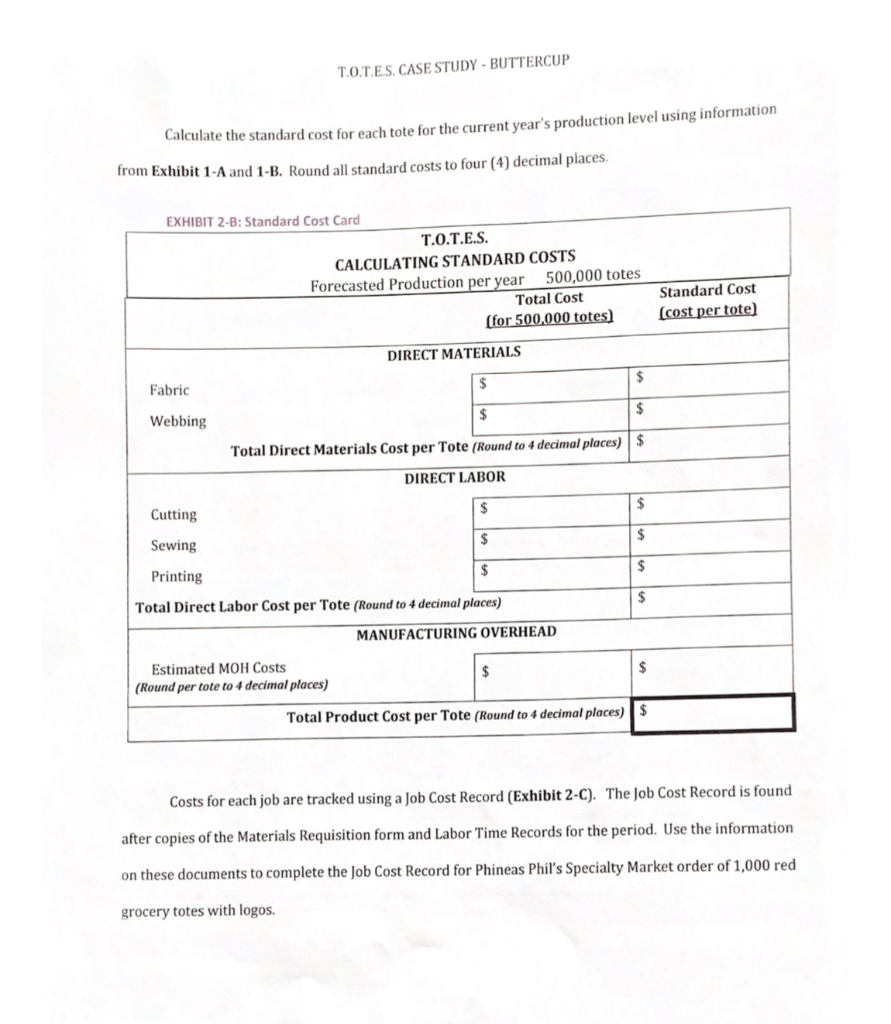

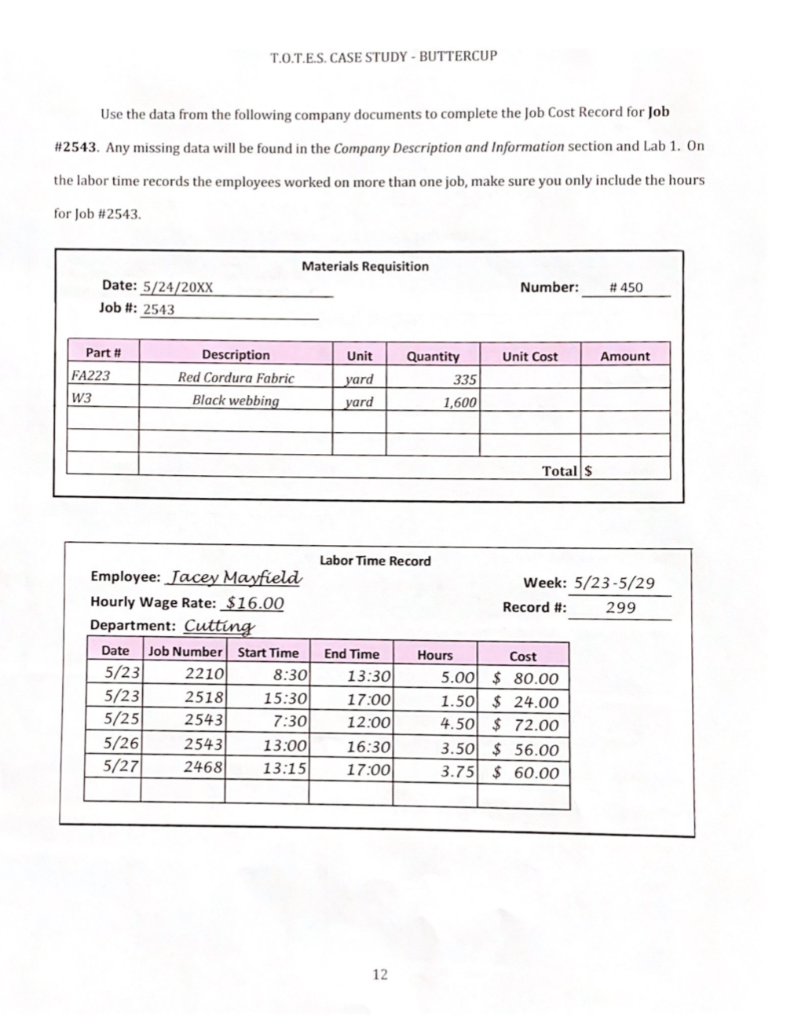

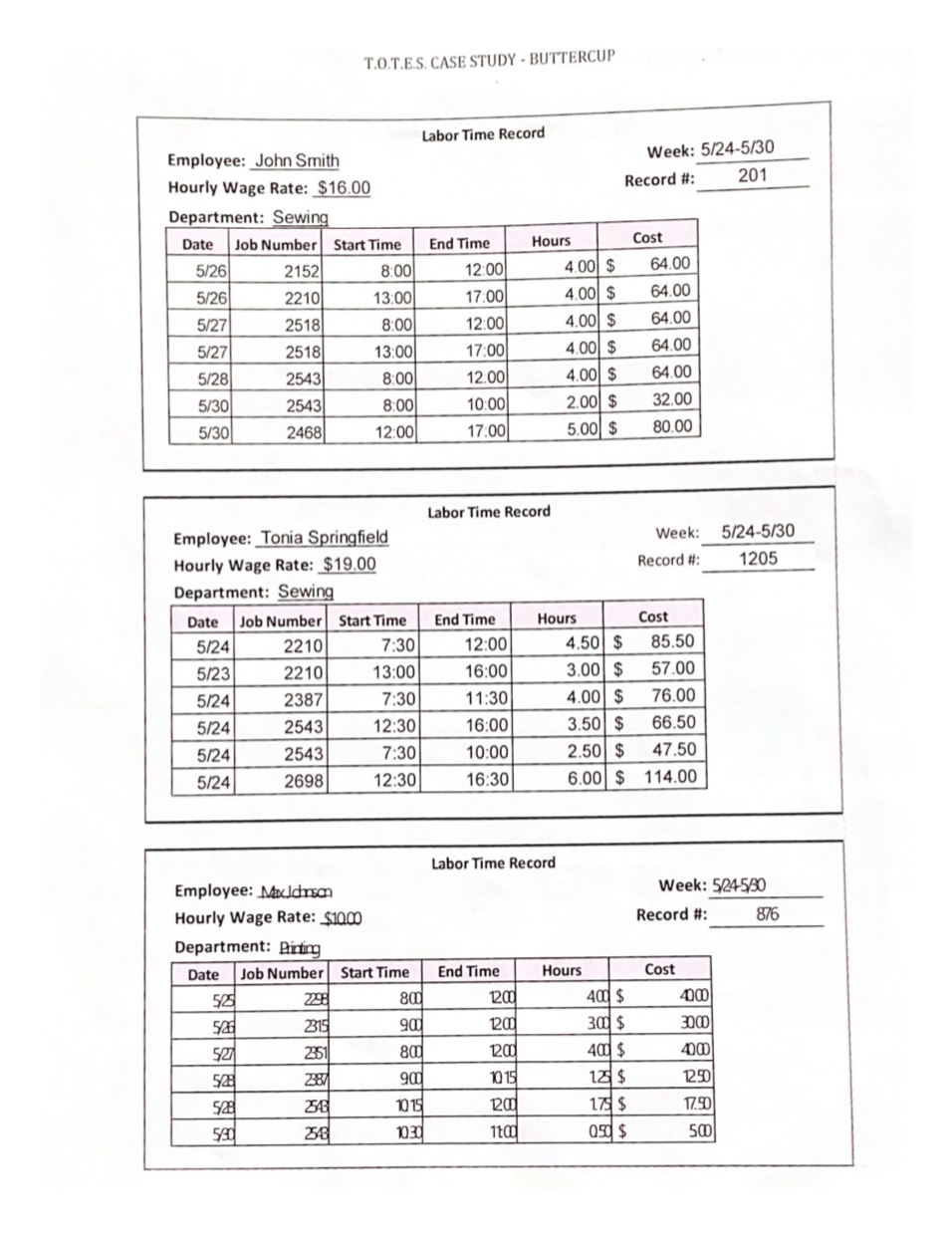

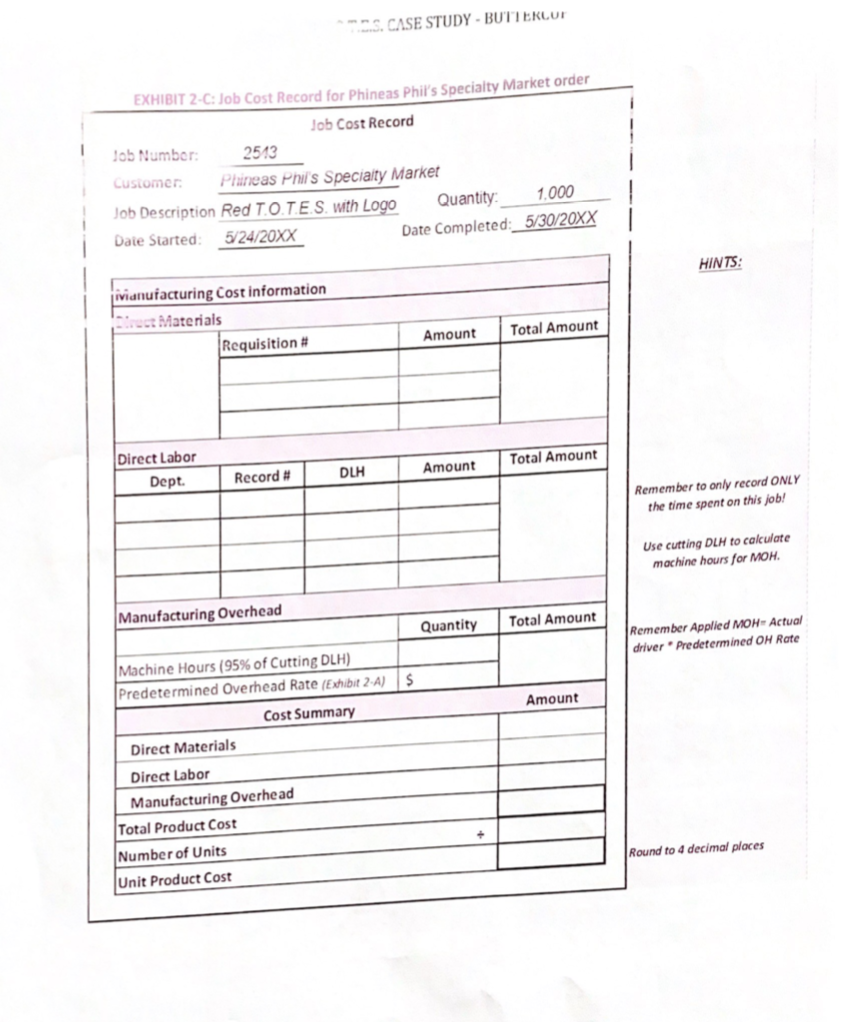

T.O.T.E.S. CASE STUDY - BUTTERCUP EXHIBIT 1-A: Classify costs as Period or Product (DM, DL or MOH) T.O.T.E.S. CLASSIFY COST Estimated Revenues And Expenses For Upcoming Year (put an X in the correct column) Forecasted Sales in units 500,000 Period Product Cost ACCOUNT NAME AMOUNT Cost DM DL MOH Sales Revenue $2,550,000 Expenses Administrative Office Supplies 3,600 Administrative Staff, e.g, accountant, etc. 125,000 Adminstrative Payroll and Fringe 116,700 SAdvertising, Trade Shows, Travel & Entertainment 46,000 Company Labels 4,200 X Depreciation - Admin. Furniture & Equipment 2,450 X Depreciation - Sewing Machines & Cutting Machines 7,600 X Equipment Lease - Administrative Offices 5,000 X xecutive Salaries 130,392X Fabric 633,333 X Factory Utilities (mixed cost) 38,000 X Freight & Postage - Administrative 2,500 Insurance - Company Liability 9,000 Insurance - Plant 14,000 Legal & Professional 5,000 X 26,000 X Plant Maintenance Supervisor 32,000 X Plant Manager 68,000 Rent - Administrative Building 11,000 X Rent - Plant Building 42,000 Repairs and Maintenance - Plant 27,000 Sales Commissions 102,000 X Sales Salaries 12,000 Shipping and Handling of Finished Product (Selling) 40,350 X Thread 50,000 X Wages - Cutting Department 84,000 Wages - Printing Department 7,875 Wages - Sewing Department 168,000 Webbing 585,000 X X Logo Ink XXY Hint: There are 15 product costs, 5 of which are direct. T.O.T.E.S. CASE STUDY - BUTTERCUP Use Excel file for Lab 1 (found on Blackboard) BEFORE completing Exhibit 1-B. Bring file to lab so that you can correct any errors. Summarize the results on Exhibit 1-B below. $2,550,000 EXHIBIT 1-B: Operating Budget Summary HINTS: T.O.T.E.S. Use Excel file Operating Budget Summary - 20XX to determine totals. at Standard SALES REVENUES Include all [ COST OF GOODS SOLD (COGS) PRODUCT $1,218,333 costs in Direct Materials COGS for a Direct Labor $250,875 traditional Manufacturing Overhead (MOH) income statement TOTAL COST OF GOODS SOLD (PRODUCT COSTS) GROSS MARGIN SELLING & ADMINSTRATIVE COSTS Include all Total Selling $200,350 PERIOD Total Administrative $410,642 expenses TOTAL SELLING & ADMIN. COSTS (PERIOD COSTS) $110.992 OPERATING INCOME (LOSS) SISZ DO $ 308,800 $4,787,008 $162,992 JOB COSTING LAB 2 T.O.T.E.S. currently uses a job costing system to allocate costs to each job. Although their products are very similar, each customer requires a different logo on their custom tote. Furthermore, Tonia and Tara have started experimenting with different sizes and lines of product in order to expand their market. Lab 2 has three parts - calculating standard costs, allocating costs to a specific job, and recording the flow of costs for that job. PART 1: Using the data from Lab Land the Company Description, students determine standard costs for direct materials, direct labor and for applied manufacturing overhead. T.O.T.E.S. uses machine hours in the cutting department for allocating manufacturing overhead. Historical records show the cutting machines operate for 95% of the hours worked by the cutting department employees. The plant operates 50 weeks per year. The company has two cutting machines. Each machine can cut 150 totes each hour On Exhibit 2-A, calculate the standard number of direct labor hours (DLH) per tote for each activity in Step 1; calculate the estimated cutting machine hours (MH) per tote in Step 2: calculate the estimated total machine-hours per year in Step 3; and calculate the plantwide manufacturing overhead rate in Step 4. Using this information, create a Standard Cost Card for totes in Exhibit 2-B. PART 2: Costs for each job are tracked using a Job Cost Record (Exhibit 2-C). Copies of the Materials Requisition form and Labor Time Records have been copied so that students can complete the Job Cost Record for Job #2543. Complete the Materials Requisition document to calculate total cost of materials for Job #2543. All totes were completed but not shipped at the end of the month. PART 3: Using Exhibit 2-D, record the flow of costs for Job #2543 through the company's inventory accounts (Raw Materials, Work in Process, Finished Goods) to Cost of Goods Sold when product is shipped. 9 T.O.T.E.S. CASE STUDY - BUTTERCUP All information is found in the Company Description and Information section and Lab 1. EXHIBIT 2-A: Calculate Standard Direct Labor Hours, Machine Hours & Predetermined Overhead Rate T.O.T.E.S. CALCULATING STANDARD COSTS Forecasted Production per year 500,000 totes DIRECT LABOR ACTIVITY STEP 1: Calculate Standard Direct Labor Hours per tote Cutting Sewing Printing a. Enter average number of hours worked per week per employee b. Number of weeks plant operates each year c Number of employees for each activity d. Total Direct labor hours (DLH) per year (a*b*c) e. DLH per tote (Step 1d #totes produced) Round to 4 decimal places totes/MH STEP 2: Calculate Estimated Cutting Machine-Hours (MH) per tote a. Production capacity for ONE cutting machine b. Machine-hours per tote (1 + Step 2a amount) Round to 4 decimal places MH/tote STEP 3: Calculate Machine-Hours used per year a. 95% of Total Cutting Direct-Labor Hours (from Step 1d) MH/year MH STEP 4: Calculate Predetermined Overhead Rate (PDOHR) and Standard MOH per tote a. Total Estimated Manufacturing Overhead (from Exhibit 1-B) $ b. Total machine-hours per year (from Step 3A) c. Predetermined Overhead Rate (Step 4a +Step 4b) Round to 4 decimal places $ per MH T.O.T.E.S. CASE STUDY - BUTTERCUP Calculate the standard cost for each tote for the current year's production level using information from Exhibit 1-A and 1-B. Round all standard costs to four (4) decimal places EXHIBIT 2-B: Standard Cost Card T.O.T.E.S. CALCULATING STANDARD COSTS Forecasted Production per year 500,000 totes Total Cost (for 500,000 totes) Standard Cost (cost per tote DIRECT MATERIALS Fabric $ $ $ $ Webbing Total Direct Materials Cost per Tote (Round to 4 decimal places) $ DIRECT LABOR $ $ Cutting $ $ Sewing $ $ Printing $ Total Direct Labor Cost per Tote (Round to 4 decimal places) MANUFACTURING OVERHEAD $ Estimated MOH Costs (Round per tote to 4 decimal places) Total Product Cost per Tote (Round to 4 decimal places) $ Costs for each job are tracked using a Job Cost Record (Exhibit 2-C). The Job Cost Record is found after copies of the Materials Requisition form and Labor Time Records for the period. Use the information on these documents to complete the Job Cost Record Phineas Phil's Specialty Market order of 1,000 red grocery totes with logos. T.O.T.E.S. CASE STUDY - BUTTERCUP Use the data from the following company documents to complete the Job Cost Record for Job #2543. Any missing data will be found in the Company Description and Information section and Lab 1. On the labor time records the employees worked on more than one job, make sure you only include the hours for Job #2543 Materials Requisition Number: # 450 Date: 5/24/20XX Job #: 2543 Unit Unit Cost Amount Part # FA223 Description Red Cordura Fabric Black webbing yard yard Quantity 335 1,600 W3 Total $ Labor Time Record Week: 5/23-5/29 Record #: 299 End Time Employee: Jacey Mayfield Hourly Wage Rate: $16.00 Department: Cutting Date Job Number Start Time 5/23 22101 8:30 5/23 2518 15:30 5/25 2543 7:30 5/26 2543 13:00 5/27 2468 13:15 13:30 17:00 12:00 16:30 17:00 Hours Cost 5.00 $ 80.00 1.50 $ 24.00 4.50 $ 72.00 3.50 $ 56.00 3.751 $ 60.00 12. T.O.T.E.S. CASE STUDY - BUTTERCUP 64.00 Labor Time Record Employee: John Smith Week: 5/24-5/30 Hourly Wage Rate: $16.00 Record #: 201 Department: Sewing Date Job Number Start Time End Time Hours Cost 5/26 2152 8:00 12:00 4.000 $ 5/26 2210 13.00 4.00 $ 64.00 5/27 2518 8:00 12.00 4.000 $ 64.00 5/27 2518 13:00 17:00 4.000 $ 64.00 5/28 2543 8:00 12.00 4.000 $ 64.00 5/30 8:00 10:00 2.000 $ 32.00 5/30 2468 12:00 17:00 5.00 $ 80.00 17.00 2543 Labor Time Record Week: 5/24-5/30 1205 Record #: Employee: Tonia Springfield Hourly Wage Rate: $19.00 Department: Sewing Date Job Number Start Time 5/24 2210 7:30 5/23 2210 13:00 5/24 2387 7:30 5/24 2543 12:30 5/24 2543 7:30 5/24 2698 12:30 End Time 12:00 16:00 11:30 16:00 10:00 16:30 Hours Cost 4.50 $ 85.50 3.00 $ 57.00 4.00 $ 76.00 3.50 $ 66.50 2.50 $ 47.50 6.00 $ 114.00 Week: 524580 Record #: 876 Cost Labor Time Record Employee: Mulderson Hourly Wage Rate: $10.00 Department: Airting Date Job Number Start Time End Time Hours 528 29 800 400 $ 521 315 900 1200 300 $ 527 28511 800 1200 400 $ 58 2871 901 1015 18$ 528 24 2015 1200 17 $ 520 26 1039 090 $ 200 4000 300 4000 120 17.0 1 50 S. CASE STUDY - BUTTERCUT EXHIBIT 2-C: Job Cost Record for Phineas Phil's Specialty Market order Job Cost Record Job Number: 2513 Customer Plineas Phil's Specialty Market Job Description Red TOTES. with Logo Quantity 1.000 Date Started 5/24/20XX Date Completed:_5/30/20XX HINTS: Ivianufacturing Cost information Materials Requisition # Amount Total Amount Total Amount Direct Labor Dept. DLH Amount Record # Remember to only record ONLY the time spent on this job! Use cutting DLH to calculate machine hours for MOH Total Amount Remember Applied MOH- Actual driver. Predetermined OH Rote Amount Manufacturing Overhead Quantity Machine Hours (95% of Cutting DLH) Predetermined Overhead Rate (Exhibit 2- AS Cost Summary Direct Materials Direct Labor Manufacturing Overhead Total Product Cost Number of Units Unit Product Cost Round to 4 decimal places T.O.T.E.S. CASE STUDY - BUTTERCUP EXHIBIT 1-A: Classify costs as Period or Product (DM, DL or MOH) T.O.T.E.S. CLASSIFY COST Estimated Revenues And Expenses For Upcoming Year (put an X in the correct column) Forecasted Sales in units 500,000 Period Product Cost ACCOUNT NAME AMOUNT Cost DM DL MOH Sales Revenue $2,550,000 Expenses Administrative Office Supplies 3,600 Administrative Staff, e.g, accountant, etc. 125,000 Adminstrative Payroll and Fringe 116,700 SAdvertising, Trade Shows, Travel & Entertainment 46,000 Company Labels 4,200 X Depreciation - Admin. Furniture & Equipment 2,450 X Depreciation - Sewing Machines & Cutting Machines 7,600 X Equipment Lease - Administrative Offices 5,000 X xecutive Salaries 130,392X Fabric 633,333 X Factory Utilities (mixed cost) 38,000 X Freight & Postage - Administrative 2,500 Insurance - Company Liability 9,000 Insurance - Plant 14,000 Legal & Professional 5,000 X 26,000 X Plant Maintenance Supervisor 32,000 X Plant Manager 68,000 Rent - Administrative Building 11,000 X Rent - Plant Building 42,000 Repairs and Maintenance - Plant 27,000 Sales Commissions 102,000 X Sales Salaries 12,000 Shipping and Handling of Finished Product (Selling) 40,350 X Thread 50,000 X Wages - Cutting Department 84,000 Wages - Printing Department 7,875 Wages - Sewing Department 168,000 Webbing 585,000 X X Logo Ink XXY Hint: There are 15 product costs, 5 of which are direct. T.O.T.E.S. CASE STUDY - BUTTERCUP Use Excel file for Lab 1 (found on Blackboard) BEFORE completing Exhibit 1-B. Bring file to lab so that you can correct any errors. Summarize the results on Exhibit 1-B below. $2,550,000 EXHIBIT 1-B: Operating Budget Summary HINTS: T.O.T.E.S. Use Excel file Operating Budget Summary - 20XX to determine totals. at Standard SALES REVENUES Include all [ COST OF GOODS SOLD (COGS) PRODUCT $1,218,333 costs in Direct Materials COGS for a Direct Labor $250,875 traditional Manufacturing Overhead (MOH) income statement TOTAL COST OF GOODS SOLD (PRODUCT COSTS) GROSS MARGIN SELLING & ADMINSTRATIVE COSTS Include all Total Selling $200,350 PERIOD Total Administrative $410,642 expenses TOTAL SELLING & ADMIN. COSTS (PERIOD COSTS) $110.992 OPERATING INCOME (LOSS) SISZ DO $ 308,800 $4,787,008 $162,992 JOB COSTING LAB 2 T.O.T.E.S. currently uses a job costing system to allocate costs to each job. Although their products are very similar, each customer requires a different logo on their custom tote. Furthermore, Tonia and Tara have started experimenting with different sizes and lines of product in order to expand their market. Lab 2 has three parts - calculating standard costs, allocating costs to a specific job, and recording the flow of costs for that job. PART 1: Using the data from Lab Land the Company Description, students determine standard costs for direct materials, direct labor and for applied manufacturing overhead. T.O.T.E.S. uses machine hours in the cutting department for allocating manufacturing overhead. Historical records show the cutting machines operate for 95% of the hours worked by the cutting department employees. The plant operates 50 weeks per year. The company has two cutting machines. Each machine can cut 150 totes each hour On Exhibit 2-A, calculate the standard number of direct labor hours (DLH) per tote for each activity in Step 1; calculate the estimated cutting machine hours (MH) per tote in Step 2: calculate the estimated total machine-hours per year in Step 3; and calculate the plantwide manufacturing overhead rate in Step 4. Using this information, create a Standard Cost Card for totes in Exhibit 2-B. PART 2: Costs for each job are tracked using a Job Cost Record (Exhibit 2-C). Copies of the Materials Requisition form and Labor Time Records have been copied so that students can complete the Job Cost Record for Job #2543. Complete the Materials Requisition document to calculate total cost of materials for Job #2543. All totes were completed but not shipped at the end of the month. PART 3: Using Exhibit 2-D, record the flow of costs for Job #2543 through the company's inventory accounts (Raw Materials, Work in Process, Finished Goods) to Cost of Goods Sold when product is shipped. 9 T.O.T.E.S. CASE STUDY - BUTTERCUP All information is found in the Company Description and Information section and Lab 1. EXHIBIT 2-A: Calculate Standard Direct Labor Hours, Machine Hours & Predetermined Overhead Rate T.O.T.E.S. CALCULATING STANDARD COSTS Forecasted Production per year 500,000 totes DIRECT LABOR ACTIVITY STEP 1: Calculate Standard Direct Labor Hours per tote Cutting Sewing Printing a. Enter average number of hours worked per week per employee b. Number of weeks plant operates each year c Number of employees for each activity d. Total Direct labor hours (DLH) per year (a*b*c) e. DLH per tote (Step 1d #totes produced) Round to 4 decimal places totes/MH STEP 2: Calculate Estimated Cutting Machine-Hours (MH) per tote a. Production capacity for ONE cutting machine b. Machine-hours per tote (1 + Step 2a amount) Round to 4 decimal places MH/tote STEP 3: Calculate Machine-Hours used per year a. 95% of Total Cutting Direct-Labor Hours (from Step 1d) MH/year MH STEP 4: Calculate Predetermined Overhead Rate (PDOHR) and Standard MOH per tote a. Total Estimated Manufacturing Overhead (from Exhibit 1-B) $ b. Total machine-hours per year (from Step 3A) c. Predetermined Overhead Rate (Step 4a +Step 4b) Round to 4 decimal places $ per MH T.O.T.E.S. CASE STUDY - BUTTERCUP Calculate the standard cost for each tote for the current year's production level using information from Exhibit 1-A and 1-B. Round all standard costs to four (4) decimal places EXHIBIT 2-B: Standard Cost Card T.O.T.E.S. CALCULATING STANDARD COSTS Forecasted Production per year 500,000 totes Total Cost (for 500,000 totes) Standard Cost (cost per tote DIRECT MATERIALS Fabric $ $ $ $ Webbing Total Direct Materials Cost per Tote (Round to 4 decimal places) $ DIRECT LABOR $ $ Cutting $ $ Sewing $ $ Printing $ Total Direct Labor Cost per Tote (Round to 4 decimal places) MANUFACTURING OVERHEAD $ Estimated MOH Costs (Round per tote to 4 decimal places) Total Product Cost per Tote (Round to 4 decimal places) $ Costs for each job are tracked using a Job Cost Record (Exhibit 2-C). The Job Cost Record is found after copies of the Materials Requisition form and Labor Time Records for the period. Use the information on these documents to complete the Job Cost Record Phineas Phil's Specialty Market order of 1,000 red grocery totes with logos. T.O.T.E.S. CASE STUDY - BUTTERCUP Use the data from the following company documents to complete the Job Cost Record for Job #2543. Any missing data will be found in the Company Description and Information section and Lab 1. On the labor time records the employees worked on more than one job, make sure you only include the hours for Job #2543 Materials Requisition Number: # 450 Date: 5/24/20XX Job #: 2543 Unit Unit Cost Amount Part # FA223 Description Red Cordura Fabric Black webbing yard yard Quantity 335 1,600 W3 Total $ Labor Time Record Week: 5/23-5/29 Record #: 299 End Time Employee: Jacey Mayfield Hourly Wage Rate: $16.00 Department: Cutting Date Job Number Start Time 5/23 22101 8:30 5/23 2518 15:30 5/25 2543 7:30 5/26 2543 13:00 5/27 2468 13:15 13:30 17:00 12:00 16:30 17:00 Hours Cost 5.00 $ 80.00 1.50 $ 24.00 4.50 $ 72.00 3.50 $ 56.00 3.751 $ 60.00 12. T.O.T.E.S. CASE STUDY - BUTTERCUP 64.00 Labor Time Record Employee: John Smith Week: 5/24-5/30 Hourly Wage Rate: $16.00 Record #: 201 Department: Sewing Date Job Number Start Time End Time Hours Cost 5/26 2152 8:00 12:00 4.000 $ 5/26 2210 13.00 4.00 $ 64.00 5/27 2518 8:00 12.00 4.000 $ 64.00 5/27 2518 13:00 17:00 4.000 $ 64.00 5/28 2543 8:00 12.00 4.000 $ 64.00 5/30 8:00 10:00 2.000 $ 32.00 5/30 2468 12:00 17:00 5.00 $ 80.00 17.00 2543 Labor Time Record Week: 5/24-5/30 1205 Record #: Employee: Tonia Springfield Hourly Wage Rate: $19.00 Department: Sewing Date Job Number Start Time 5/24 2210 7:30 5/23 2210 13:00 5/24 2387 7:30 5/24 2543 12:30 5/24 2543 7:30 5/24 2698 12:30 End Time 12:00 16:00 11:30 16:00 10:00 16:30 Hours Cost 4.50 $ 85.50 3.00 $ 57.00 4.00 $ 76.00 3.50 $ 66.50 2.50 $ 47.50 6.00 $ 114.00 Week: 524580 Record #: 876 Cost Labor Time Record Employee: Mulderson Hourly Wage Rate: $10.00 Department: Airting Date Job Number Start Time End Time Hours 528 29 800 400 $ 521 315 900 1200 300 $ 527 28511 800 1200 400 $ 58 2871 901 1015 18$ 528 24 2015 1200 17 $ 520 26 1039 090 $ 200 4000 300 4000 120 17.0 1 50 S. CASE STUDY - BUTTERCUT EXHIBIT 2-C: Job Cost Record for Phineas Phil's Specialty Market order Job Cost Record Job Number: 2513 Customer Plineas Phil's Specialty Market Job Description Red TOTES. with Logo Quantity 1.000 Date Started 5/24/20XX Date Completed:_5/30/20XX HINTS: Ivianufacturing Cost information Materials Requisition # Amount Total Amount Total Amount Direct Labor Dept. DLH Amount Record # Remember to only record ONLY the time spent on this job! Use cutting DLH to calculate machine hours for MOH Total Amount Remember Applied MOH- Actual driver. Predetermined OH Rote Amount Manufacturing Overhead Quantity Machine Hours (95% of Cutting DLH) Predetermined Overhead Rate (Exhibit 2- AS Cost Summary Direct Materials Direct Labor Manufacturing Overhead Total Product Cost Number of Units Unit Product Cost Round to 4 decimal places

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts