Question: I DO NOT need/want a full solution! I am needing to know how to deal with knowing the efficiency ahead of time. Please guide me

I DO NOT need/want a full solution! I am needing to know how to deal with knowing the efficiency ahead of time. Please guide me in the right direction.

Here is the equation for efficiency!

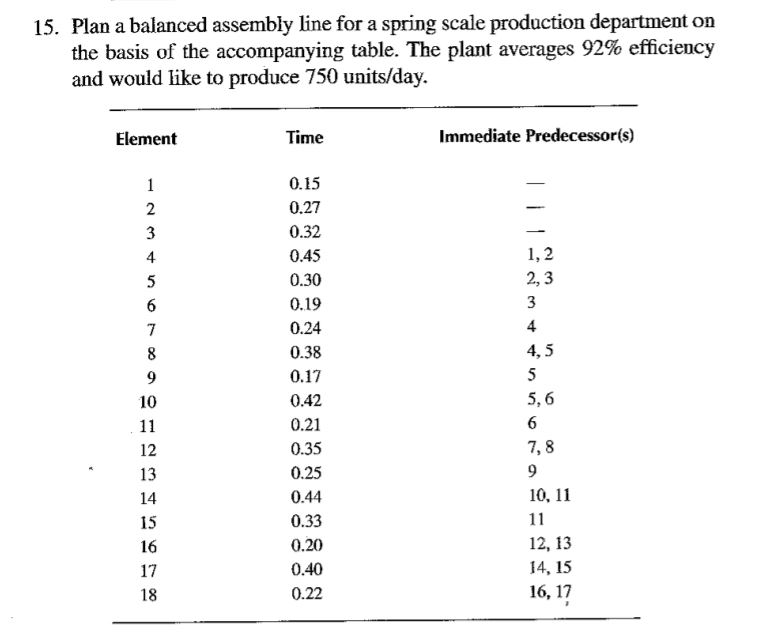

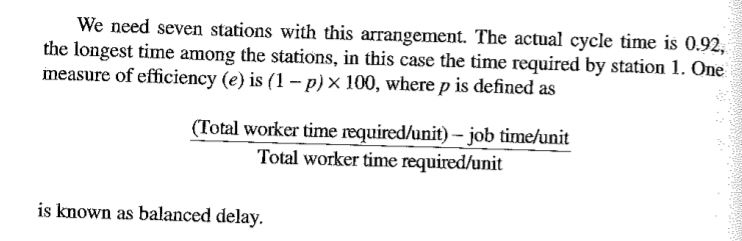

15. Plan a balanced assembly line for a spring scale production department on the basis of the accompanying table. The plant averages 92% efficiency and would like to produce 750 units/day. Element Time Immediate Predecessor(s) 1 2 3 4 1,2 2,3 3 4 4,5 5 0.15 0.27 0.32 0.45 0.30 0.19 0.24 0.38 0.17 0.42 0.21 0.35 0.25 0.44 0.33 0.20 0.40 0.22 5 6 7 8 9 10 11 12 13 14 15 16 17 18 5,6 6 7,8 9 10, 11 11 12, 13 14, 15 16, 17 We need seven stations with this arrangement. The actual cycle time is 0.92, the longest time among the stations, in this case the time required by station 1. One measure of efficiency (e) is (1-p) x 100, where p is defined as (Total worker time required/unit) - job time/unit Total worker time required/unit is known as balanced delay

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts