Question: I just need help with some problems, can you explain to me step by step how to get it. please and thank you IgnmentMain.do?inprogress=true A04

I just need help with some problems, can you explain to me step by step how to get it. please and thank you

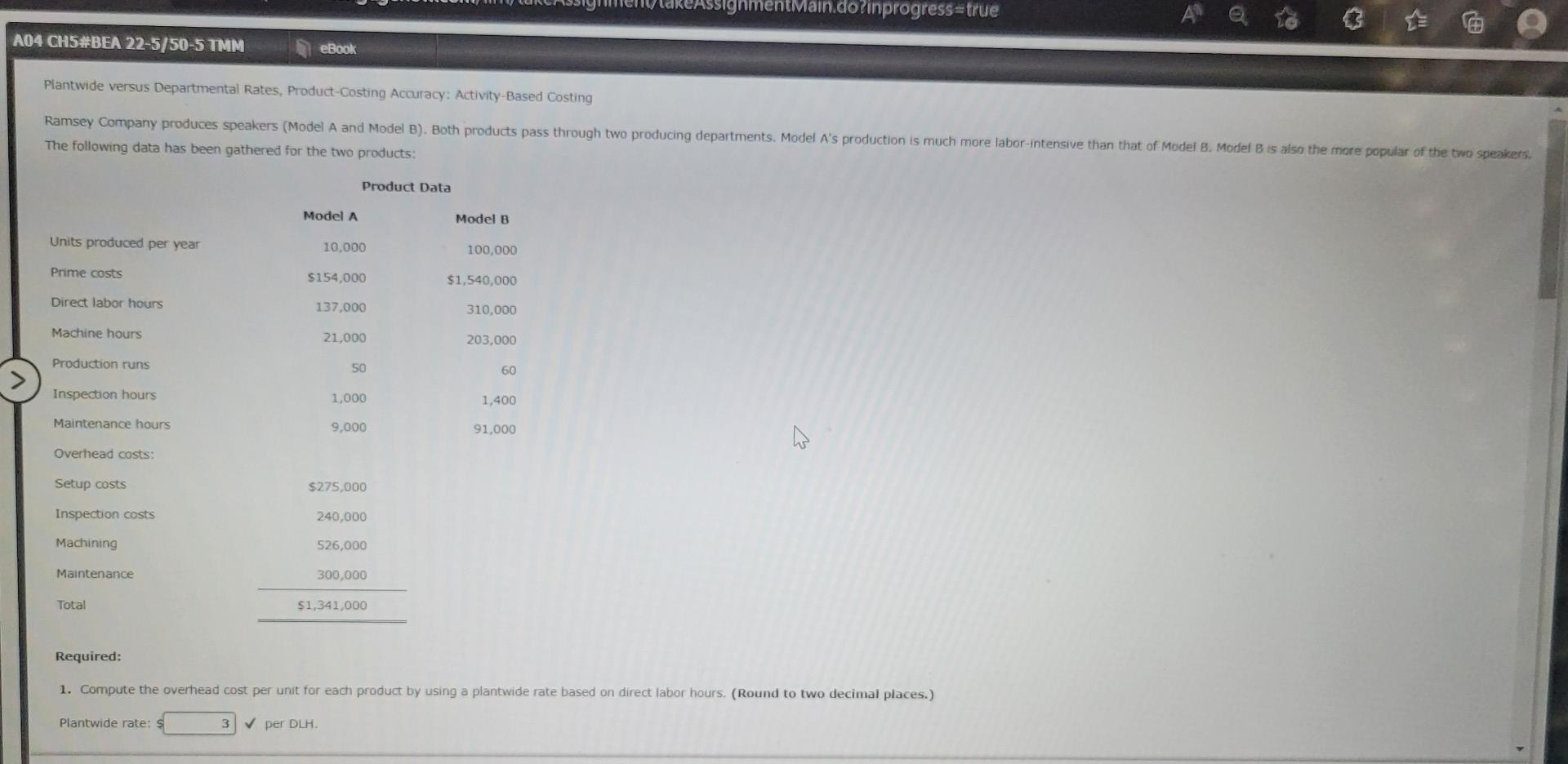

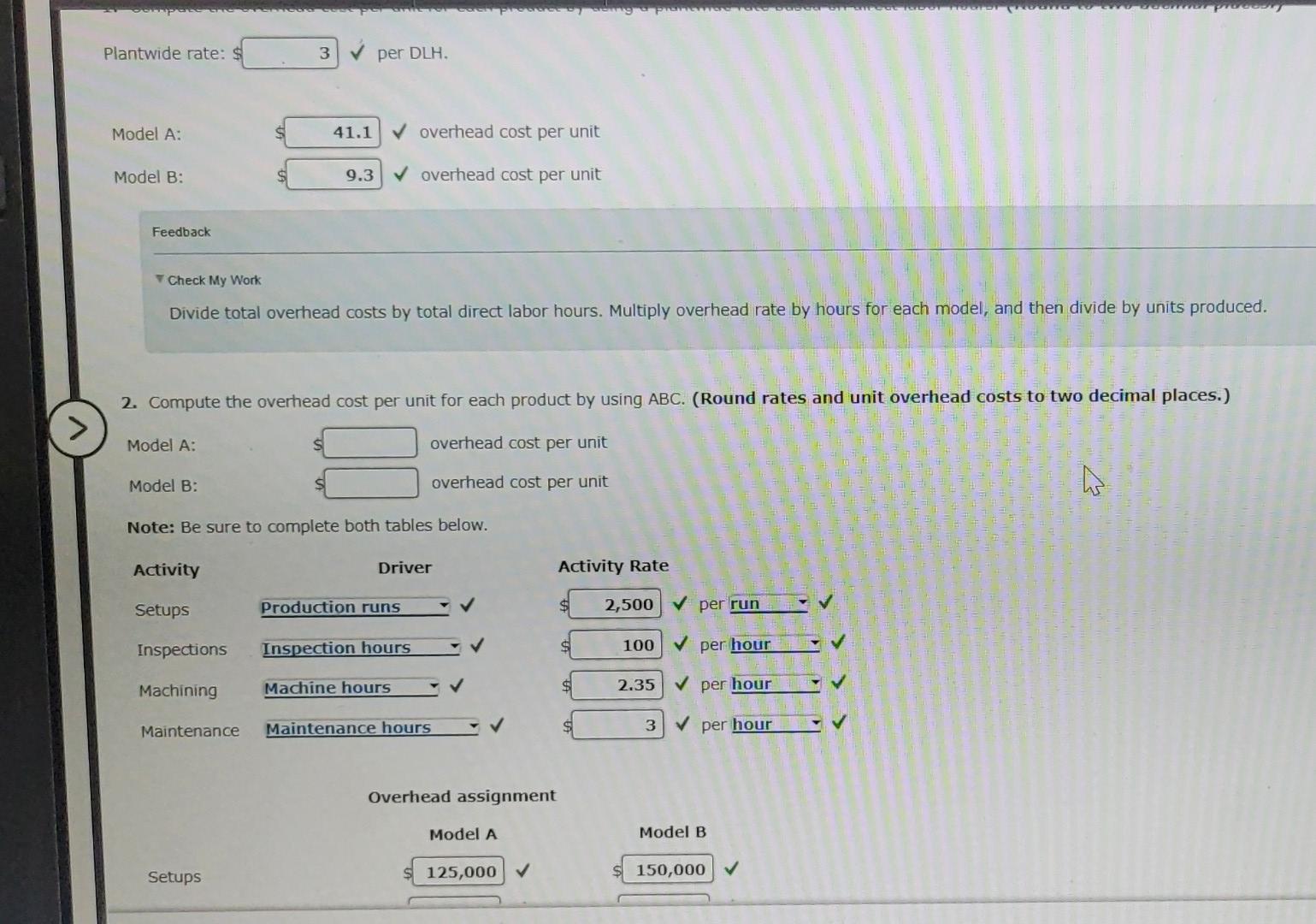

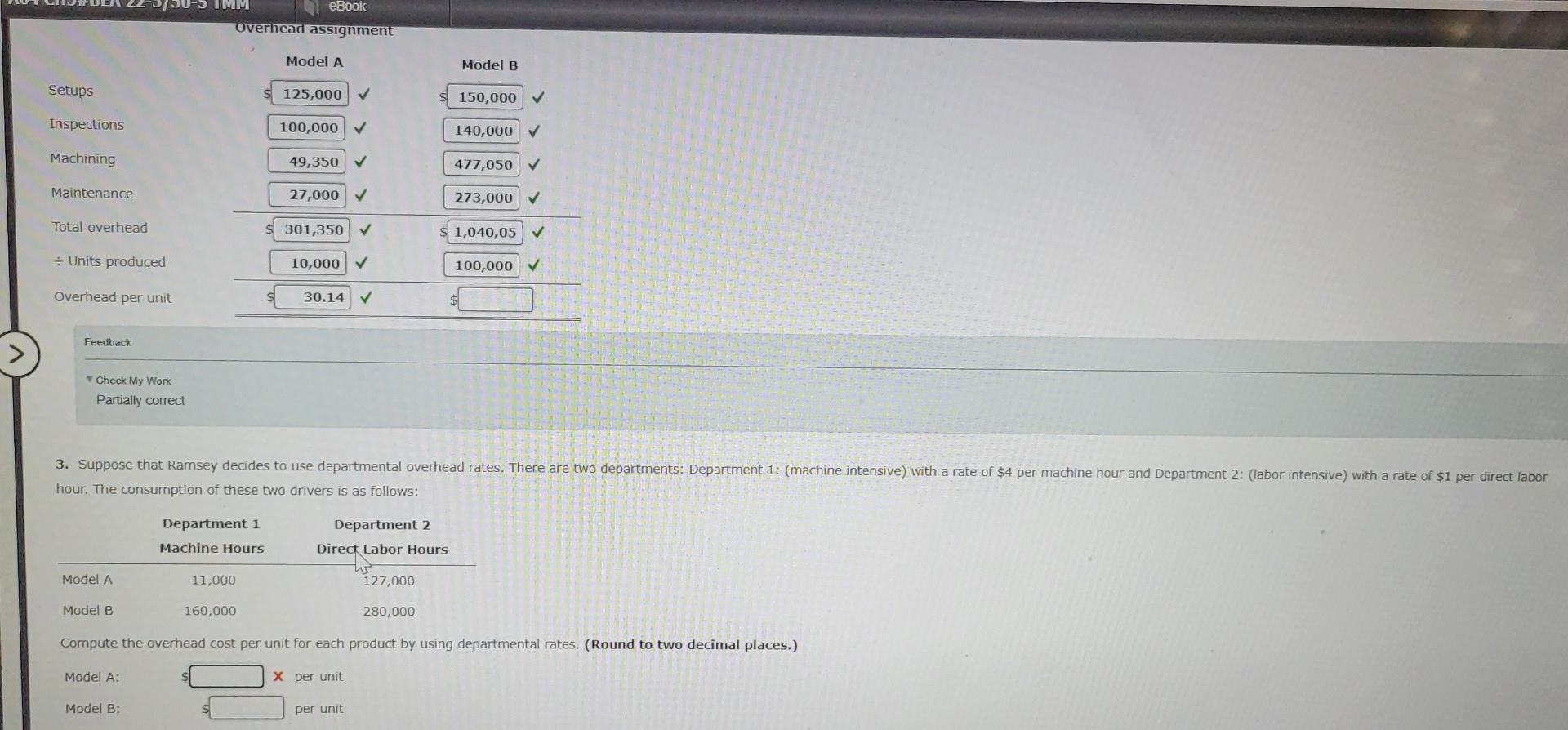

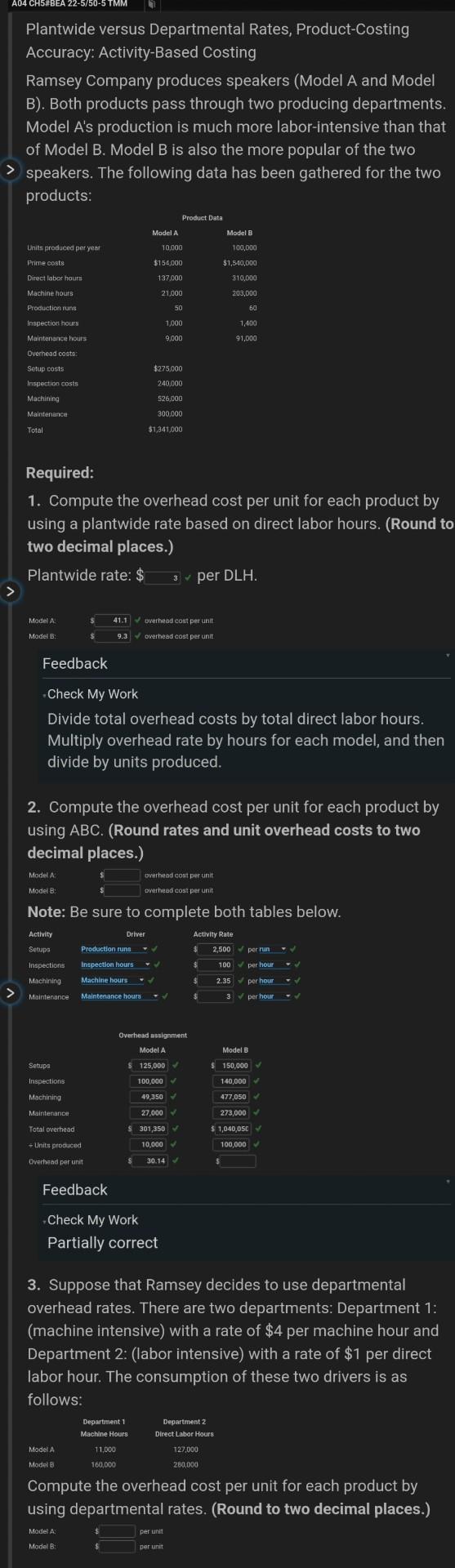

IgnmentMain.do?inprogress=true A04 CH5#BEA 22-5/50-5 TMM eBook Plantwide versus Departmental Rates, Product-Costing Accuracy: Activity-Based Costing Ramsey Company produces speakers (Model A and Model B). Both products pass through two producing departments. Model A's production is much more labor-intensive than that of Model B. Model B is also the more popular of the two speakers. The following data has been gathered for the two products: Product Data Model A Model B Units produced per year 10,000 100,000 Prime costs $154,000 $1,540,000 Direct labor hours 137.000 310,000 Machine hours 21,000 203,000 Production runs 50 60 Inspection hours 1,000 1,400 Maintenance hours 9,000 91,000 Overhead costs: Setup costs $275,000 Inspection costs 240,000 Machining 526,000 Maintenance 300,000 Total $1,341,000 Required: 1. Compute the overhead cost per unit for each product by using a plantwide rate based on direct labor hours. (Round to two decimal places.) Plantwide rate: S 3 per DLH Plantwide rate: $ 3 per DLH. Model A: 41.1 overhead cost per unit Model B: 9.3 overhead cost per unit Feedback Check My Work Divide total overhead costs by total direct labor hours. Multiply overhead rate by hours for each model, and then divide by units produced. 2. Compute the overhead cost per unit for each product by using ABC. (Round rates and unit ou cos to two decimal places.) > Model A: overhead cost per unit Model B: overhead cost per unit M Note: Be sure to complete both tables below. Activity Driver Activity Rate Setups Production runs 2,500 per run Inspections Inspection hours 100 per hour Machining Machine hours 2.35 per hour Maintenance Maintenance hours $ 3 per hour Overhead assignment Model A Model B Setups 125,000 $ 150,000 IMM eBook Overhead assignment Model A Model B Setups 125,000 150,000 Inspections 100,000 140,000 Machining 49,350 477,050 Maintenance 27,000 273,000 Total overhead 301,350 $ 1,040,05 Units produced 10,000 100,000 Overhead per unit 30.14 Feedback Check My Work Partially correct 3. Suppose that Ramsey decides to use departmental overhead rates. There are two departments: Department 1: (machine intensive) with a rate of $4 per machine hour and Department 2: (labor intensive) with a rate of $1 per direct labor hour. The consumption of these two drivers is as follows: Department 1 Machine Hours Department 2 Direct Labor Hours w 127,000 Model A 11,000 Model B 160,000 280,000 Compute the overhead cost per unit for each product by using departmental rates. (Round to two decimal places.) Model A: X per unit Model B: per unit A04 CH5#BEA 22-5/50-5 TMM Plantwide versus Departmental Rates, Product-Costing Accuracy: Activity-Based Costing Ramsey Company produces speakers (Model A and Model B). Both products pass through two producing departments. Model A's production is much more labor-intensive than that of Model B. Model B is also the more popular of the two speakers. The following data has been gathered for the two products: > Product Data Madel A Model B 10,000 100,000 Units produced per year Prime costs Direct labor hours $154,000 $1,540,000 310,000 137,000 21.000 Machine hours 203,000 Production runs 50 60 Inspection hours 1,000 1,400 Maintenance hours 9,000 91,000 Overhead costs Setup costs $275,000 Inspection costs 240,000 526,000 Machining Maintenance 300,000 Total $1,341,000 Required: 1. Compute the overhead cost per unit for each product by using a plantwide rate based on direct labor hours. (Round to two decimal places.) Plantwide rate: $ 3 per DLH. Model A s 41.1 overhead cost per unit Model: 9.3 ~ overhead cost per unit Feedback Check My Work Divide total overhead costs by total direct labor hours. Multiply overhead rate by hours for each model, and then divide by units produced. 2. Compute the overhead cost per unit for each product by using ABC. (Round rates and unit overhead costs to two decimal places.) Model A : Model: overhead cost per unit Overhead cost per unit Note: Be sure to complete both tables below. Driver Activity Rate Activity Setups Production runs $ 2,500 per run 100 per hour per hour Inspections Inspection hours $ Machining Machine hours $ 2.35 per hour > Maintenance Maintenance hours $ 3 per hour Model B Overhead assignment Model A $ 125,000 100,000 Setups $ 150,000 Inspections 140,000 Machining 49,350 477,050 Maintenance 27,000 273,000 Total overhead S 301,350 $ 1,040,050 - Units produced 10,000 100,000 Overhead perunt 30.14 Feedback Check My Work Partially correct 3. Suppose that Ramsey decides to use departmental overhead rates. There are two departments: Department 1: (machine intensive) with a rate of $4 per machine hour and Department 2: (labor intensive) with a rate of $1 per direct labor hour. The consumption of these two drivers is as follows: Department1 Machine Hours 11,000 160,000 Department 2 Direct Labor Hours 127,000 280,000 Model A Model B Compute the overhead cost per unit for each product by using departmental rates. (Round to two decimal places.) Model A per un Model B: per unit IgnmentMain.do?inprogress=true A04 CH5#BEA 22-5/50-5 TMM eBook Plantwide versus Departmental Rates, Product-Costing Accuracy: Activity-Based Costing Ramsey Company produces speakers (Model A and Model B). Both products pass through two producing departments. Model A's production is much more labor-intensive than that of Model B. Model B is also the more popular of the two speakers. The following data has been gathered for the two products: Product Data Model A Model B Units produced per year 10,000 100,000 Prime costs $154,000 $1,540,000 Direct labor hours 137.000 310,000 Machine hours 21,000 203,000 Production runs 50 60 Inspection hours 1,000 1,400 Maintenance hours 9,000 91,000 Overhead costs: Setup costs $275,000 Inspection costs 240,000 Machining 526,000 Maintenance 300,000 Total $1,341,000 Required: 1. Compute the overhead cost per unit for each product by using a plantwide rate based on direct labor hours. (Round to two decimal places.) Plantwide rate: S 3 per DLH Plantwide rate: $ 3 per DLH. Model A: 41.1 overhead cost per unit Model B: 9.3 overhead cost per unit Feedback Check My Work Divide total overhead costs by total direct labor hours. Multiply overhead rate by hours for each model, and then divide by units produced. 2. Compute the overhead cost per unit for each product by using ABC. (Round rates and unit ou cos to two decimal places.) > Model A: overhead cost per unit Model B: overhead cost per unit M Note: Be sure to complete both tables below. Activity Driver Activity Rate Setups Production runs 2,500 per run Inspections Inspection hours 100 per hour Machining Machine hours 2.35 per hour Maintenance Maintenance hours $ 3 per hour Overhead assignment Model A Model B Setups 125,000 $ 150,000 IMM eBook Overhead assignment Model A Model B Setups 125,000 150,000 Inspections 100,000 140,000 Machining 49,350 477,050 Maintenance 27,000 273,000 Total overhead 301,350 $ 1,040,05 Units produced 10,000 100,000 Overhead per unit 30.14 Feedback Check My Work Partially correct 3. Suppose that Ramsey decides to use departmental overhead rates. There are two departments: Department 1: (machine intensive) with a rate of $4 per machine hour and Department 2: (labor intensive) with a rate of $1 per direct labor hour. The consumption of these two drivers is as follows: Department 1 Machine Hours Department 2 Direct Labor Hours w 127,000 Model A 11,000 Model B 160,000 280,000 Compute the overhead cost per unit for each product by using departmental rates. (Round to two decimal places.) Model A: X per unit Model B: per unit A04 CH5#BEA 22-5/50-5 TMM Plantwide versus Departmental Rates, Product-Costing Accuracy: Activity-Based Costing Ramsey Company produces speakers (Model A and Model B). Both products pass through two producing departments. Model A's production is much more labor-intensive than that of Model B. Model B is also the more popular of the two speakers. The following data has been gathered for the two products: > Product Data Madel A Model B 10,000 100,000 Units produced per year Prime costs Direct labor hours $154,000 $1,540,000 310,000 137,000 21.000 Machine hours 203,000 Production runs 50 60 Inspection hours 1,000 1,400 Maintenance hours 9,000 91,000 Overhead costs Setup costs $275,000 Inspection costs 240,000 526,000 Machining Maintenance 300,000 Total $1,341,000 Required: 1. Compute the overhead cost per unit for each product by using a plantwide rate based on direct labor hours. (Round to two decimal places.) Plantwide rate: $ 3 per DLH. Model A s 41.1 overhead cost per unit Model: 9.3 ~ overhead cost per unit Feedback Check My Work Divide total overhead costs by total direct labor hours. Multiply overhead rate by hours for each model, and then divide by units produced. 2. Compute the overhead cost per unit for each product by using ABC. (Round rates and unit overhead costs to two decimal places.) Model A : Model: overhead cost per unit Overhead cost per unit Note: Be sure to complete both tables below. Driver Activity Rate Activity Setups Production runs $ 2,500 per run 100 per hour per hour Inspections Inspection hours $ Machining Machine hours $ 2.35 per hour > Maintenance Maintenance hours $ 3 per hour Model B Overhead assignment Model A $ 125,000 100,000 Setups $ 150,000 Inspections 140,000 Machining 49,350 477,050 Maintenance 27,000 273,000 Total overhead S 301,350 $ 1,040,050 - Units produced 10,000 100,000 Overhead perunt 30.14 Feedback Check My Work Partially correct 3. Suppose that Ramsey decides to use departmental overhead rates. There are two departments: Department 1: (machine intensive) with a rate of $4 per machine hour and Department 2: (labor intensive) with a rate of $1 per direct labor hour. The consumption of these two drivers is as follows: Department1 Machine Hours 11,000 160,000 Department 2 Direct Labor Hours 127,000 280,000 Model A Model B Compute the overhead cost per unit for each product by using departmental rates. (Round to two decimal places.) Model A per un Model B: per unit

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts