Question: I need a complete and professional answer for Q#3 ONLY. please guys try to make it sense with Q1 &Q2 answers below. thanks in advance

I need a complete and professional answer for Q#3 ONLY. please guys try to make it sense with Q1 &Q2 answers below. thanks in advance COARSE NAME: procurment & contract Mgmt.

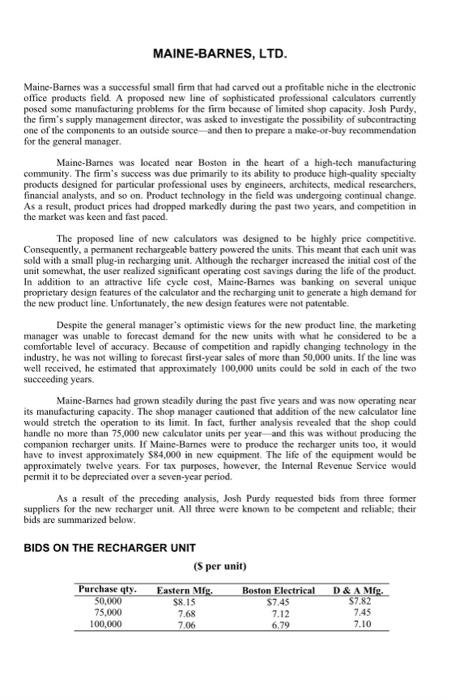

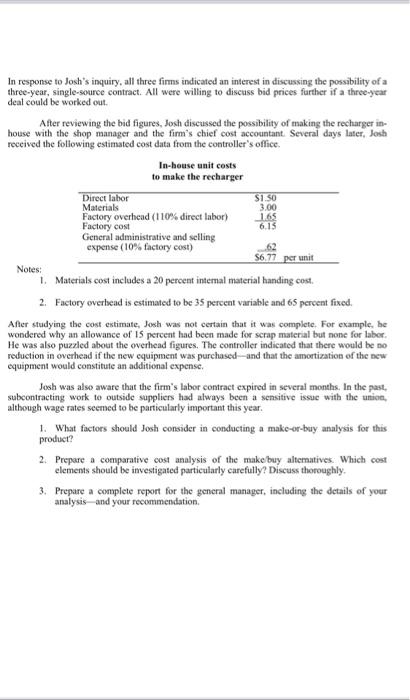

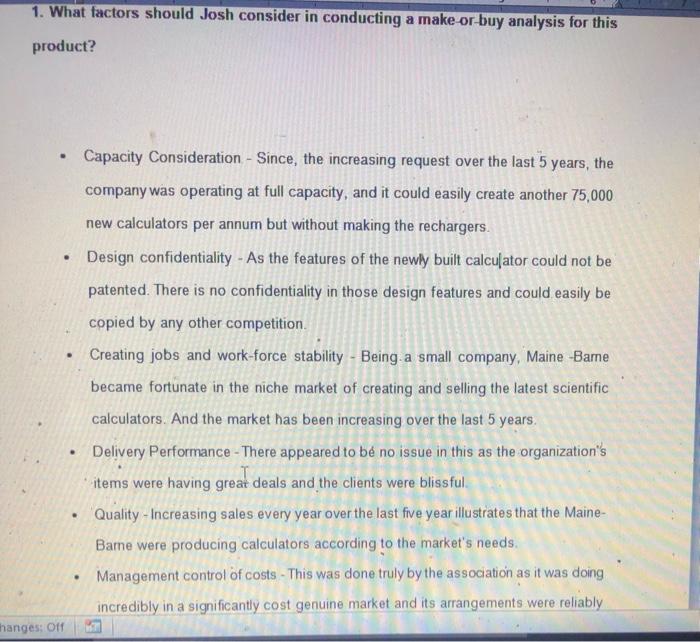

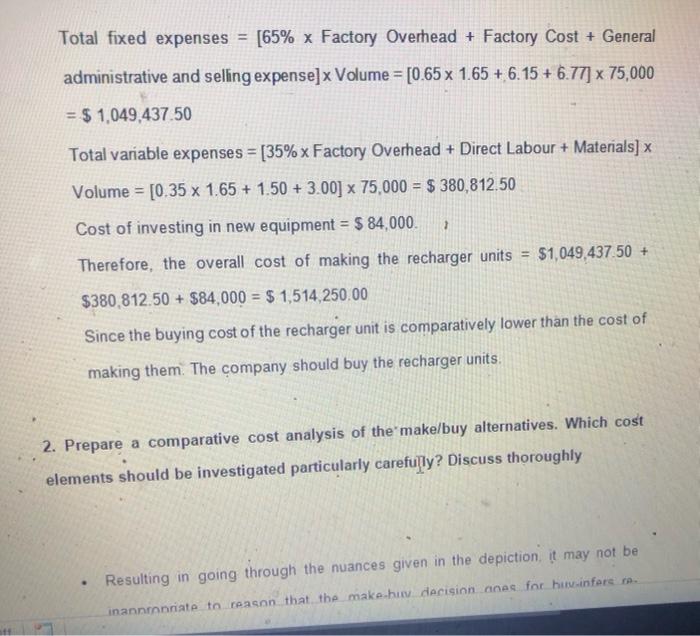

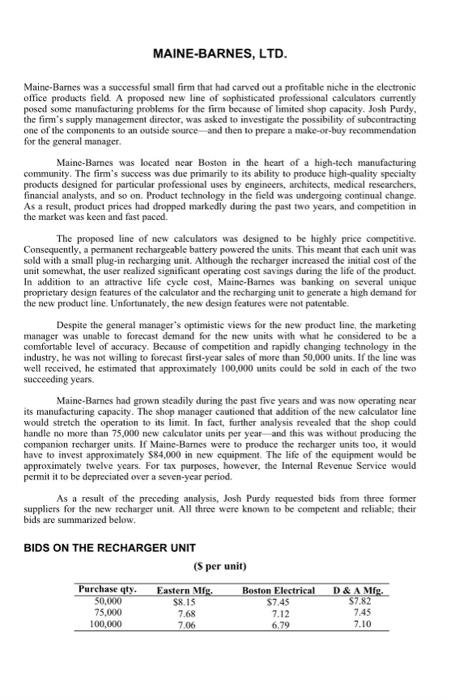

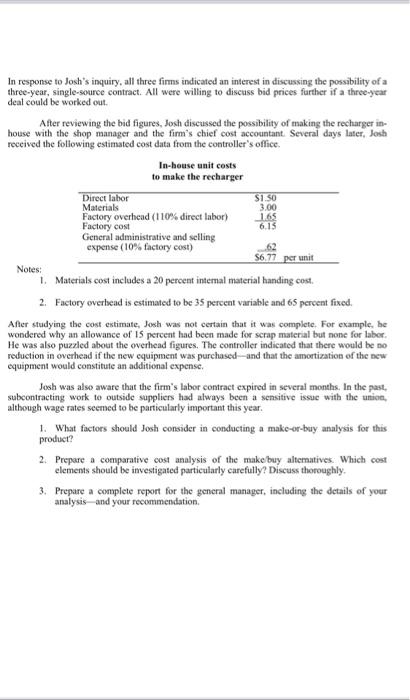

MAINE-BARNES, LTD. Maine-Barnes was a successful small firm that had carved out a profitable niche in the electronic office products field. A proposed new line of sophisticated professional calculators currently posed some manufacturing problems for the firm because of limited shop capacity. Josh Purdy, the firm's supply management director, was asked to investigate the possibility of subcontracting one of the components to an outside source and then to prepare a make-or-buy recommendation for the general manager Maine-Barnes was located near Boston in the heart of a high-tech manufacturing community. The firm's success was due primarily to its ability to produce high-quality specialty products designed for particular professional uses by engineers, architects, medical researchers, financial analysts, and so on. Product technology in the field was undergoing continual change. As a result, product prices had dropped markedly during the past two years, and competition in the market was keen and fast paced. The proposed line of new calculators was designed to be highly price competitive. Consequently, a permanent rechargeable battery powered the units. This meant that each unit was sold with a small plug-in techarging unit. Although the recharger increased the initial cost of the unit somewhat, the user realized significant operating cost savings during the life of the product. In addition to an attractive life cycle cost, Maine-Bames was banking on several unique proprietary design features of the calculator and the recharging unit to generate a high demand for the new product line. Unfortunately, the new design features were not patentable. Despite the general manager's optimistic views for the new product line, the marketing manager was unable to forecast demand for the new units with what he considered to be a comfortable level of accuracy. Because of competition and rapidly changing technology in the industry, he was not willing to forecast first-year sales of more than 50,000 units. If the line was well received, he estimated that approximately 100,000 units could be sold in each of the two succeeding years. Maine-Barnes had grown steadily during the past five years and was now operating near its manufacturing capacity. The shop manager cautioned that addition of the new calculator line would stretch the operation to its limit. In fact, further analysis revealed that the shop could handle no more than 75,000 new calculator units per year and this was without producing the companion recharger units. If Maine-Bames were to produce the recharger units too, it would have to invest approximately $84.000 in new equipment. The life of the equipment would be approximately twelve years. For tax purposes, however, the Internal Revenue Service would permit it to be depreciated over a seven-year period. As a result of the preceding analysis, Josh Purdy requested bids from three former suppliers for the new recharger unit. All three were known to be competent and reliable, their bids are summarized below. BIDS ON THE RECHARGER UNIT (s per unit) Purchase qty. Eastern Mfg. Boston Electrical 50,000 S8.15 $7.45 75,000 7.68 7.12 100,000 7.06 6.79 D&A Mr. $7.82 7.45 7.10 In response to Josh's inquiry, all three fimms indicated an interest in discussing the possibility of a three-year, single-source contract. All were willing to discuss bid prices further if a three-year deal could be worked out. After reviewing the bid figures, Josh discussed the possibility of making the recharger in- house with the shop manager and the firm's chief cost accountant. Several days later, Josh received the following estimated cost data from the controller's office In-house unit costs to make the recharger Direct labor S1.50 Materials 3.00 Factory overhead (110% direct labor 1.65 Factory cost 6.13 General administrative and selling expense (10% factory cost) $6.77 per unit Notes: 1. Materials cost includes a 20 percent interal material handing cost. 2. Factory overhead is estimated to be 35 percent variable and 65 percent fixed. After studying the cost estimate, Josh was not certain that it was complete. For example, he wondered why an allowance of 15 percent had been made for scrap material but none for labor. He was also puzzled about the overhead figures. The controller indicated that there would be no reduction in overhead if the new equipment was purchased and that the amortization of the new equipment would constitute an additional expense. Josh was also aware that the firm's labor contract expired in several months. In the past, subcontracting work to outside suppliers had always been a sensitive issue with the union, although wage rates seemed to be particularly important this year. 1. What factors should Josh consider in conducting a make-or-buy analysis for this product? 2. Prepare a comparative cost analysis of the make buy alternatives. Which cost elements should be investigated particularly carefully? Discuss thoroughly. 3. Prepare a complete report for the general manager, including the details of your analysis and your recommendation, 1. What factors should Josh consider in conducting a make or buy analysis for this product? . Capacity Consideration - Since, the increasing request over the last 5 years, the company was operating at full capacity, and it could easily create another 75,000 new calculators per annum but without making the rechargers. Design confidentiality - As the features of the newly built calculator could not be patented. There is no confidentiality in those design features and could easily be copied by any other competition. Creating jobs and work-force stability - Being a small company, Maine -Bame became fortunate in the niche market of creating and selling the latest scientific calculators. And the market has been increasing over the last 5 years. . Delivery Performance - There appeared to be no issue in this as the organization's items were having great deals and the clients were blissful. Quality - Increasing sales every year over the last five year illustrates that the Maine- Bame were producing calculators according to the market's needs. Management control of costs - This was done truly by the association as it was doing incredibly in a significantly cost genuine market and its arrangements were reliably thanges: Ott Total fixed expenses = [65% x Factory Overhead + Factory Cost + General administrative and selling expense] x Volume = [0.65 x 1.65 +6.15 + 6.77] x 75,000 = $ 1.049,437.50 Total variable expenses = [35% x Factory Overhead + Direct Labour + Materials] X Volume = [0.35 x 1.65 + 1.50 + 3.00] x 75,000 = $ 380,812.50 7 Cost of investing in new equipment = $ 84,000 Therefore, the overall cost of making the recharger units = $1,049,437.50 + $380,812.50 + $84,000 = $ 1,514,250.00 Since the buying cost of the recharger unit is comparatively lower than the cost of making them. The company should buy the recharger units. 2. Prepare a comparative cost analysis of the make/buy alternatives. Which cost elements should be investigated particularly carefully? Discuss thoroughly Resulting in going through the nuances given in the depiction, it may not be inanmpriate to reason that the make his decision coes for hus.inferra 2. Prepare a comparative cost analysis of the make/buy alternatives. Which cost elements should be investigated particularly carefully? Discuss thoroughly . Resulting in going through the nuances given in the depiction, it may not be inappropriate to reason that the make-buy decision goes for buy-infers re- . appropriating as opposed to meandering in the in-house formation of recharger. Initially the current limit is as a rule completely used and there are factors concerning the augmentations to the limit expected for in-house production. Also New adventure as much as $84,000 is normal for updating the breaking point which is a negative variable for in-house creation Apparently that the issues like arrangement secret and control of significant worth are better dealt with through in-house creation. At the same time, the mechanical changes at a faster speed and genuine competition in the space of undertakings correspondingly support for out-getting and that too with the presence of strong suppliers at competitive rates. I . As per the depiction, Josh has surveyedits creation cost of $6.77 per unit which is not the rates given by the bidders. At any rate there are not well characterized circumstances about the evaluation of in-house cost of creation and there exists possibilities of diminishing in bidder's rates. . On correlation it is observed that the most minimal bidder is Boston Electricals with rates $6.79, $7.12, and $7.45 for request sizes 100,000, 75,000 and 50,000 separately Keeping in view a lot of issues about the in-house creation combined with questionable interest, it very well might be fitting to pay even a piece extra when contrasted with in-house cost of creation and out obtained the rechargers from Boston Electricals or from other provider with additional exchanges on the offers

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock