Question: I need a work order from this given case study. Thank you. Case Study Having a work order system, an operator writes a work order.

I need a work order from this given case study. Thank you.

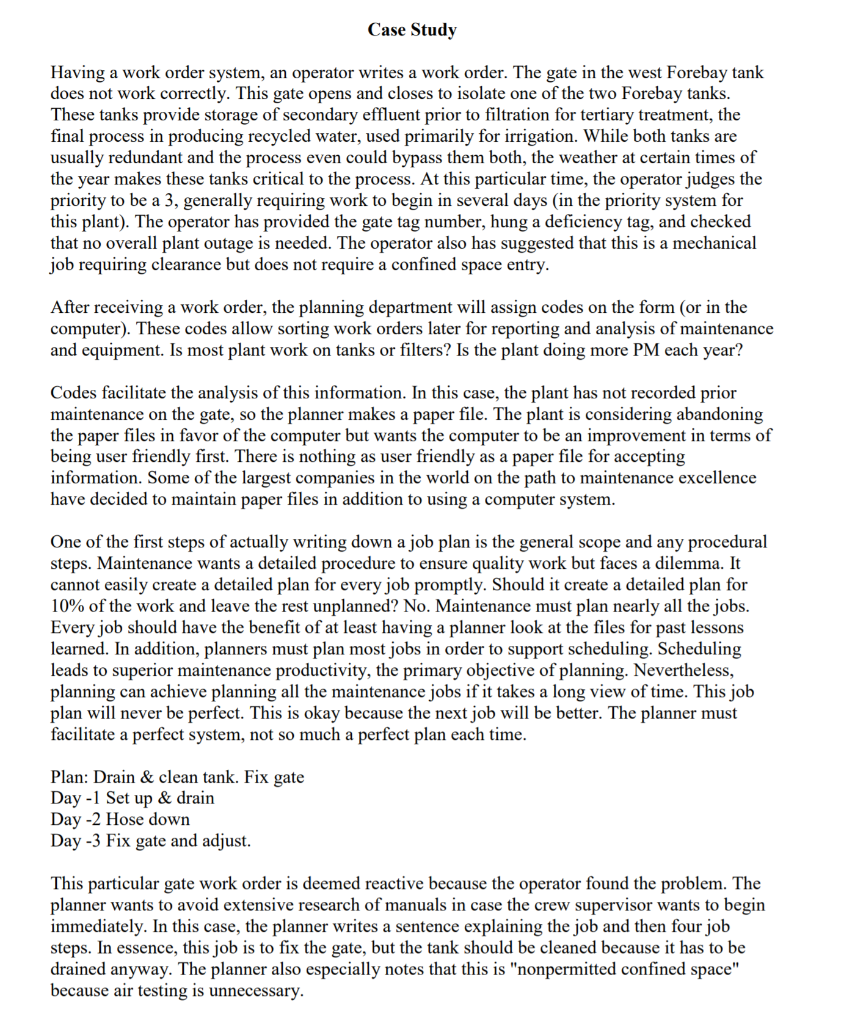

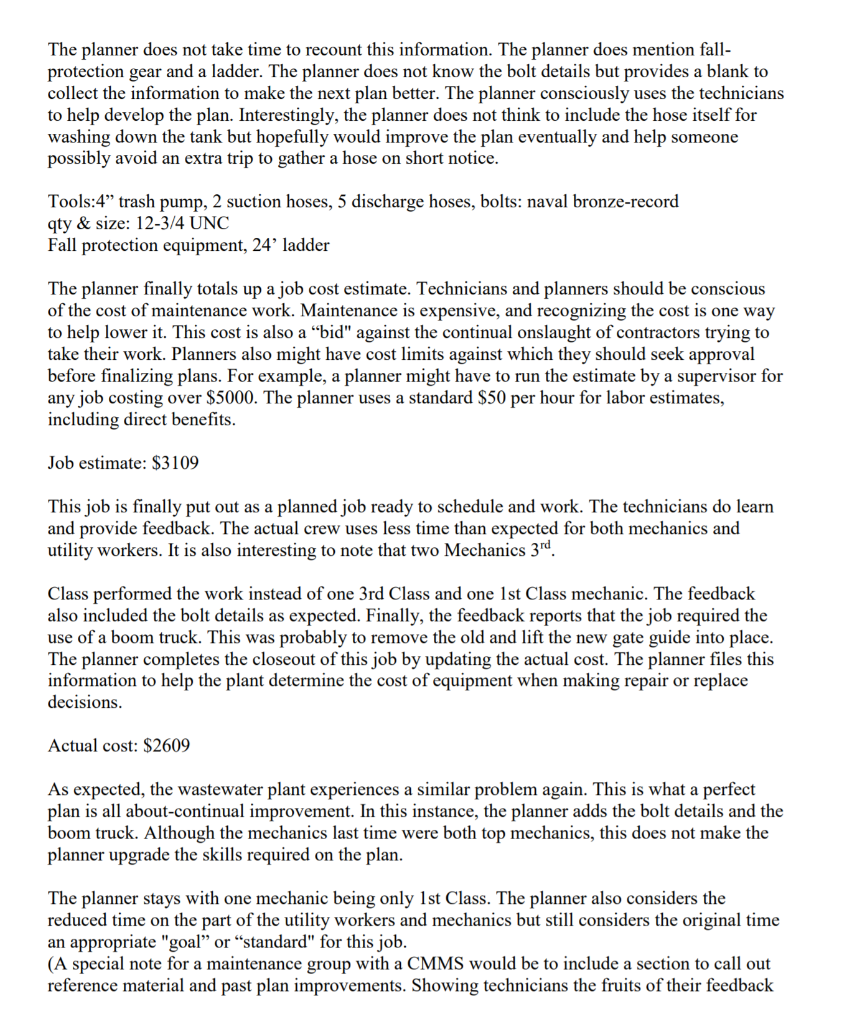

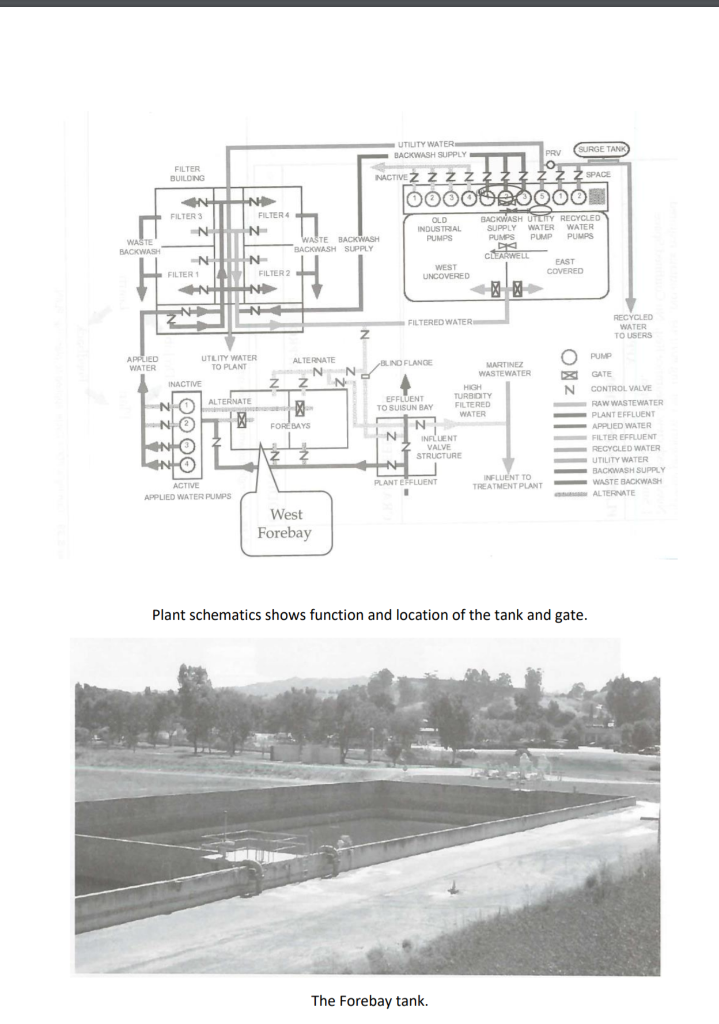

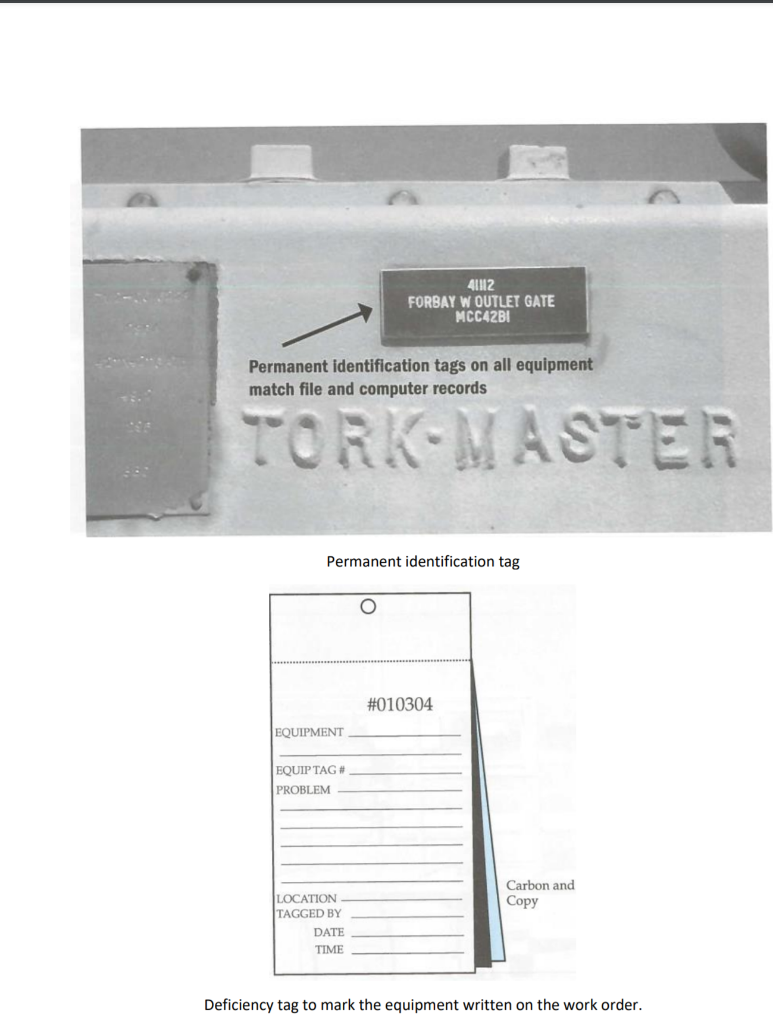

Case Study Having a work order system, an operator writes a work order. The gate in the west Forebay tank does not work correctly. This gate opens and closes to isolate one of the two Forebay tanks. These tanks provide storage of secondary effluent prior to filtration for tertiary treatment, the final process in producing recycled water, used primarily for irrigation. While both tanks are usually redundant and the process even could bypass them both, the weather at certain times of the year makes these tanks critical to the process. At this particular time, the operator judges the priority to be a 3, generally requiring work to begin in several days (in the priority system for this plant). The operator has provided the gate tag number, hung a deficiency tag, and checked that no overall plant outage is needed. The operator also has suggested that this is a mechanical job requiring clearance but does not require a confined space entry. After receiving a work order, the planning department will assign codes on the form (or in the computer). These codes allow sorting work orders later for reporting and analysis of maintenance and equipment. Is most plant work on tanks or filters? Is the plant doing more PM each year? Codes facilitate the analysis of this information. In this case, the plant has not recorded prior maintenance on the gate, so the planner makes a paper file. The plant is considering abandoning the paper files in favor of the computer but wants the computer to be an improvement in terms of being user friendly first. There is nothing as user friendly as a paper file for accepting information. Some of the largest companies in the world on the path to maintenance excellence have decided to maintain paper files in addition to using a computer system. One of the first steps of actually writing down a job plan is the general scope and any procedural steps. Maintenance wants a detailed procedure to ensure quality work but faces a dilemma. It cannot easily create a detailed plan for every job promptly. Should it create a detailed plan for 10% of the work and leave the rest unplanned? No. Maintenance must plan nearly all the jobs. Every job should have the benefit of at least having a planner look at the files for past lessons learned. In addition, planners must plan most jobs in order to support scheduling. Scheduling leads to superior maintenance productivity, the primary objective of planning. Nevertheless, planning can achieve planning all the maintenance jobs if it takes a long view of time. This job plan will never be perfect. This is okay because the next job will be better. The planner must facilitate a perfect system, not so much a perfect plan each time. Plan: Drain & clean tank. Fix gate Day-1 Set up & drain Day -2 Hose down Day -3 Fix gate and adjust. This particular gate work order is deemed reactive because the operator found the problem. The planner wants to avoid extensive research of manuals in case the crew supervisor wants to begin immediately. In this case, the planner writes a sentence explaining the job and then four job steps. In essence, this job is to fix the gate, but the tank should be cleaned because it has to be drained anyway. The planner also especially notes that this is "nonpermitted confined space" because air testing is unnecessary. The next issue is to identify the required skills to complete the work. The planner wants to identify the lowest skills necessary to give the supervisor the most flexibility in assigning the work. Even though the gate adjustment itself requires two mechanics, only one needs considerable expertise. The planner puts in one Mechanic 3rd Class (the highest skill) and one Mechanic 1st Class; the planner does not include two Mechanics 3rd Class. Similarly, the draining and cleaning require only general utility workers. Next, the planner considers labor hours. Rather than use complex built-up estimates, the planner simply uses personal best judgment for the time good technicians should take to perform a "smooth job. A smooth job would have no unanticipated delays. Development of super precise estimates is usually not possible owing to the nature of maintenance work. This is not an assembly line. Extra time developing estimates does not create estimates that are more precise and often wastes limited planner time. In addition, experience has shown that such estimates are useful for assigning work and creating schedules, even though they are not precisely accurate. They are still useful because the estimate is a good median, and as many jobs run over as under the estimated time. These useful estimates are achieved when planners have extensive craft experience. The plant includes the labor hours on the printed work orders for the technicians. They are adults and need to gauge their efforts against the target. Supervisors give them enough work each day for an entire shift. Dayl - 2 utility workers 4 hr Day2 - 3 utility workers 7 hr Day3 - 1 Mech 3rd class 4 hr 1 Mech 1st class 4 hr 2 utility workers 4 hr Next, the planner considers parts. The planner may not be able to identify parts on more reactive work the first time. Yet the planner can be an excellent clerk to file and retrieve the part numbers discovered on previous work. On this gate job, there was no history, but the planner was able to specify the part number from the inventory system. If any nonstock purchases been required, the planning department would lead the purchasing effort. Note that the planner includes the cost. The technician needs this information to judge whether the part should be handled especially carefully. Labor: Total labor 45 hr Job duration 2.5 day Parts:gate guide #7843-2 qty:1 Cost:$859 Tools for this job include a pump and lengths of hose to drain the tank. The technicians know to connect the lengths together and where to drain the discharged water. The planner does not take time to recount this information. The planner does mention fall- protection gear and a ladder. The planner does not know the bolt details but provides a blank to collect the information to make the next plan better. The planner consciously uses the technicians to help develop the plan. Interestingly, the planner does not think to include the hose itself for washing down the tank but hopefully would improve the plan eventually and help someone possibly avoid an extra trip to gather a hose on short notice. Tools:4 trash pump, 2 suction hoses, 5 discharge hoses, bolts: naval bronze-record qty & size: 12-3/4 UNC Fall protection equipment, 24' ladder The planner finally totals up a job cost estimate. Technicians and planners should be conscious of the cost of maintenance work. Maintenance is expensive, and recognizing the cost is one way to help lower it. This cost is also a bid" against the continual onslaught of contractors trying to take their work. Planners also might have cost limits against which they should seek approval before finalizing plans. For example, a planner might have to run the estimate by a supervisor for any job costing over $5000. The planner uses a standard $50 per hour for labor estimates, including direct benefits. Job $3109 This job is finally put out as a planned job ready to schedule and work. The technicians do learn and provide feedback. The actual crew uses less time than expected for both mechanics and utility workers. It is also interesting to note that two Mechanics 3rd. Class performed the work instead of one 3rd Class and one 1st Class mechanic. The feedback also included the bolt details as expected. Finally, the feedback reports that the job required the use of a boom truck. This was probably to remove the old and lift the new gate guide into place. The planner completes the closeout of this job by updating the actual cost. The planner files this information to help the plant determine the cost of equipment when making repair or replace decisions. Actual cost: $2609 As expected, the wastewater plant experiences a similar problem again. This is what a perfect plan is all about-continual improvement. In this instance, the planner adds the bolt details and the boom truck. Although the mechanics last time were both top mechanics, this does not make the planner upgrade the skills required on the plan. The planner stays with one mechanic being only 1st Class. The planner also considers the reduced time on the part of the utility workers and mechanics but still considers the original time an appropriate "goal" or "standard" for this job. (A special note for a maintenance group with a CMMS would be to include a section to call out reference material and past plan improvements. Showing technicians the fruits of their feedback on the job plans encourages their participation in the system. In the presentation slide, the plan portion has been enlarged, and the feedback and coding would be on a subsequent page.) Thus, with every maintenance cycle, the plan approaches perfection-hence the perfect job plan. UTIUTY WATER BACKWASH SUPPLY SURGE TANK FILTER BUILDING PRV NACTIVEZ Z ZZZZZ Z Z SPACE OOOOOOOOO IN FILTER 3 N WASTE BACKWASH N' FILTERS OLD INDUSTRIAL PUMPS BACKWASH UTILITY RECYCLED SUPPLY WATER WATER PUMOS PUMP PUMPS FILTER 4 N WASTE BACKWASH BACKWASH SUPPLY N FILTER 2 CLEANWELL WEST UNCOVERED EAST COVERED TUIN -N FILTERED WATER z RECYCLED WATER TO USERS ALTERNATE N N Z N Z APPLIED UTLITY WATER WATER TO PLANT INACTIVE NO ALTERNATE NO M INIO CNL FOREBAYS BLIND FLANGE MARTINEZ WASTEWATER HIGH EFFLUENT TURBIDITY TO SUISUN BAY FILTERED WATER N N INFLUENT VALVE STRUCTURE N PLANT EFFLUENT INFLUENT TO TREATMENT PLANT PUMP X GATE N CONTROL VALVE RAW WASTEWATER PLANT EFFLUENT APPLED WATER FILTER EFFLUENT RECYCLED WATER UTILITY WATER BACKWASH SUPPL WASTE BACKWASH ALTERNATE ACTIVE APPLIED WATER PUMPS West Forebay Plant schematics shows function and location of the tank and gate. The Forebay tank. 4112 FORBAY W OUTLET GATE MCC42B! Permanent identification tags on all equipment match file and computer records TORK MASTER Permanent identification tag #010304 EQUIPMENT EQUIP TAG # PROBLEM Carbon and Copy LOCATION TAGGED BY DATE TIME Deficiency tag to mark the equipment written on the work order. Case Study Having a work order system, an operator writes a work order. The gate in the west Forebay tank does not work correctly. This gate opens and closes to isolate one of the two Forebay tanks. These tanks provide storage of secondary effluent prior to filtration for tertiary treatment, the final process in producing recycled water, used primarily for irrigation. While both tanks are usually redundant and the process even could bypass them both, the weather at certain times of the year makes these tanks critical to the process. At this particular time, the operator judges the priority to be a 3, generally requiring work to begin in several days (in the priority system for this plant). The operator has provided the gate tag number, hung a deficiency tag, and checked that no overall plant outage is needed. The operator also has suggested that this is a mechanical job requiring clearance but does not require a confined space entry. After receiving a work order, the planning department will assign codes on the form (or in the computer). These codes allow sorting work orders later for reporting and analysis of maintenance and equipment. Is most plant work on tanks or filters? Is the plant doing more PM each year? Codes facilitate the analysis of this information. In this case, the plant has not recorded prior maintenance on the gate, so the planner makes a paper file. The plant is considering abandoning the paper files in favor of the computer but wants the computer to be an improvement in terms of being user friendly first. There is nothing as user friendly as a paper file for accepting information. Some of the largest companies in the world on the path to maintenance excellence have decided to maintain paper files in addition to using a computer system. One of the first steps of actually writing down a job plan is the general scope and any procedural steps. Maintenance wants a detailed procedure to ensure quality work but faces a dilemma. It cannot easily create a detailed plan for every job promptly. Should it create a detailed plan for 10% of the work and leave the rest unplanned? No. Maintenance must plan nearly all the jobs. Every job should have the benefit of at least having a planner look at the files for past lessons learned. In addition, planners must plan most jobs in order to support scheduling. Scheduling leads to superior maintenance productivity, the primary objective of planning. Nevertheless, planning can achieve planning all the maintenance jobs if it takes a long view of time. This job plan will never be perfect. This is okay because the next job will be better. The planner must facilitate a perfect system, not so much a perfect plan each time. Plan: Drain & clean tank. Fix gate Day-1 Set up & drain Day -2 Hose down Day -3 Fix gate and adjust. This particular gate work order is deemed reactive because the operator found the problem. The planner wants to avoid extensive research of manuals in case the crew supervisor wants to begin immediately. In this case, the planner writes a sentence explaining the job and then four job steps. In essence, this job is to fix the gate, but the tank should be cleaned because it has to be drained anyway. The planner also especially notes that this is "nonpermitted confined space" because air testing is unnecessary. The next issue is to identify the required skills to complete the work. The planner wants to identify the lowest skills necessary to give the supervisor the most flexibility in assigning the work. Even though the gate adjustment itself requires two mechanics, only one needs considerable expertise. The planner puts in one Mechanic 3rd Class (the highest skill) and one Mechanic 1st Class; the planner does not include two Mechanics 3rd Class. Similarly, the draining and cleaning require only general utility workers. Next, the planner considers labor hours. Rather than use complex built-up estimates, the planner simply uses personal best judgment for the time good technicians should take to perform a "smooth job. A smooth job would have no unanticipated delays. Development of super precise estimates is usually not possible owing to the nature of maintenance work. This is not an assembly line. Extra time developing estimates does not create estimates that are more precise and often wastes limited planner time. In addition, experience has shown that such estimates are useful for assigning work and creating schedules, even though they are not precisely accurate. They are still useful because the estimate is a good median, and as many jobs run over as under the estimated time. These useful estimates are achieved when planners have extensive craft experience. The plant includes the labor hours on the printed work orders for the technicians. They are adults and need to gauge their efforts against the target. Supervisors give them enough work each day for an entire shift. Dayl - 2 utility workers 4 hr Day2 - 3 utility workers 7 hr Day3 - 1 Mech 3rd class 4 hr 1 Mech 1st class 4 hr 2 utility workers 4 hr Next, the planner considers parts. The planner may not be able to identify parts on more reactive work the first time. Yet the planner can be an excellent clerk to file and retrieve the part numbers discovered on previous work. On this gate job, there was no history, but the planner was able to specify the part number from the inventory system. If any nonstock purchases been required, the planning department would lead the purchasing effort. Note that the planner includes the cost. The technician needs this information to judge whether the part should be handled especially carefully. Labor: Total labor 45 hr Job duration 2.5 day Parts:gate guide #7843-2 qty:1 Cost:$859 Tools for this job include a pump and lengths of hose to drain the tank. The technicians know to connect the lengths together and where to drain the discharged water. The planner does not take time to recount this information. The planner does mention fall- protection gear and a ladder. The planner does not know the bolt details but provides a blank to collect the information to make the next plan better. The planner consciously uses the technicians to help develop the plan. Interestingly, the planner does not think to include the hose itself for washing down the tank but hopefully would improve the plan eventually and help someone possibly avoid an extra trip to gather a hose on short notice. Tools:4 trash pump, 2 suction hoses, 5 discharge hoses, bolts: naval bronze-record qty & size: 12-3/4 UNC Fall protection equipment, 24' ladder The planner finally totals up a job cost estimate. Technicians and planners should be conscious of the cost of maintenance work. Maintenance is expensive, and recognizing the cost is one way to help lower it. This cost is also a bid" against the continual onslaught of contractors trying to take their work. Planners also might have cost limits against which they should seek approval before finalizing plans. For example, a planner might have to run the estimate by a supervisor for any job costing over $5000. The planner uses a standard $50 per hour for labor estimates, including direct benefits. Job $3109 This job is finally put out as a planned job ready to schedule and work. The technicians do learn and provide feedback. The actual crew uses less time than expected for both mechanics and utility workers. It is also interesting to note that two Mechanics 3rd. Class performed the work instead of one 3rd Class and one 1st Class mechanic. The feedback also included the bolt details as expected. Finally, the feedback reports that the job required the use of a boom truck. This was probably to remove the old and lift the new gate guide into place. The planner completes the closeout of this job by updating the actual cost. The planner files this information to help the plant determine the cost of equipment when making repair or replace decisions. Actual cost: $2609 As expected, the wastewater plant experiences a similar problem again. This is what a perfect plan is all about-continual improvement. In this instance, the planner adds the bolt details and the boom truck. Although the mechanics last time were both top mechanics, this does not make the planner upgrade the skills required on the plan. The planner stays with one mechanic being only 1st Class. The planner also considers the reduced time on the part of the utility workers and mechanics but still considers the original time an appropriate "goal" or "standard" for this job. (A special note for a maintenance group with a CMMS would be to include a section to call out reference material and past plan improvements. Showing technicians the fruits of their feedback on the job plans encourages their participation in the system. In the presentation slide, the plan portion has been enlarged, and the feedback and coding would be on a subsequent page.) Thus, with every maintenance cycle, the plan approaches perfection-hence the perfect job plan. UTIUTY WATER BACKWASH SUPPLY SURGE TANK FILTER BUILDING PRV NACTIVEZ Z ZZZZZ Z Z SPACE OOOOOOOOO IN FILTER 3 N WASTE BACKWASH N' FILTERS OLD INDUSTRIAL PUMPS BACKWASH UTILITY RECYCLED SUPPLY WATER WATER PUMOS PUMP PUMPS FILTER 4 N WASTE BACKWASH BACKWASH SUPPLY N FILTER 2 CLEANWELL WEST UNCOVERED EAST COVERED TUIN -N FILTERED WATER z RECYCLED WATER TO USERS ALTERNATE N N Z N Z APPLIED UTLITY WATER WATER TO PLANT INACTIVE NO ALTERNATE NO M INIO CNL FOREBAYS BLIND FLANGE MARTINEZ WASTEWATER HIGH EFFLUENT TURBIDITY TO SUISUN BAY FILTERED WATER N N INFLUENT VALVE STRUCTURE N PLANT EFFLUENT INFLUENT TO TREATMENT PLANT PUMP X GATE N CONTROL VALVE RAW WASTEWATER PLANT EFFLUENT APPLED WATER FILTER EFFLUENT RECYCLED WATER UTILITY WATER BACKWASH SUPPL WASTE BACKWASH ALTERNATE ACTIVE APPLIED WATER PUMPS West Forebay Plant schematics shows function and location of the tank and gate. The Forebay tank. 4112 FORBAY W OUTLET GATE MCC42B! Permanent identification tags on all equipment match file and computer records TORK MASTER Permanent identification tag #010304 EQUIPMENT EQUIP TAG # PROBLEM Carbon and Copy LOCATION TAGGED BY DATE TIME Deficiency tag to mark the equipment written on the work orderStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock