Question: I need answer in detail CASE STUDY 10.1 Attribute Control Charts: np Charts PART 1 At Fruits and Such, a local frozen fruit concentrate manufacturer,

I need answer in detail

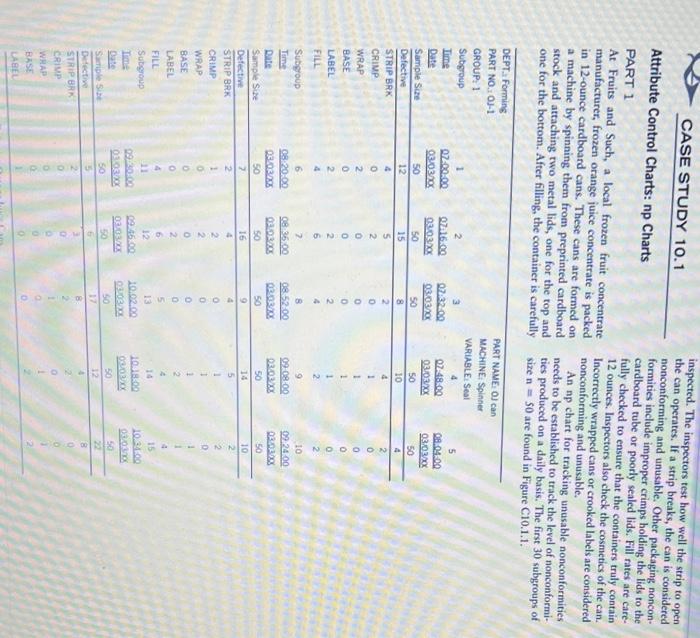

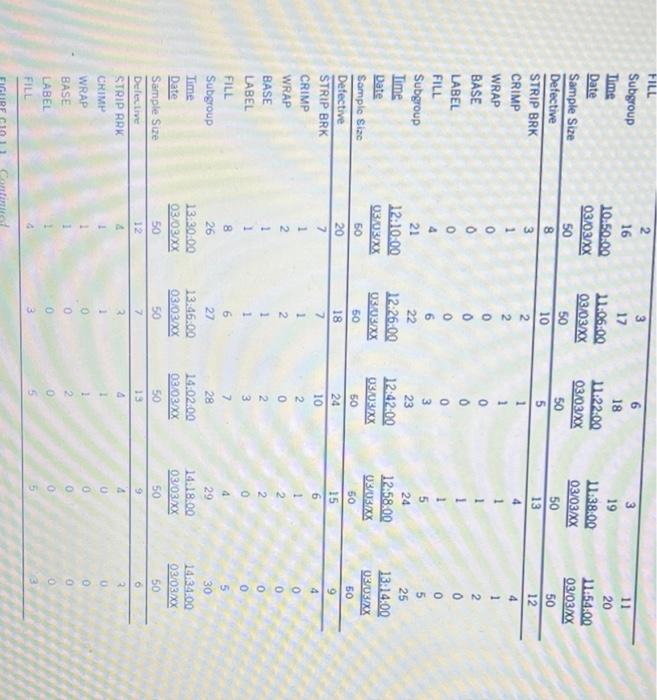

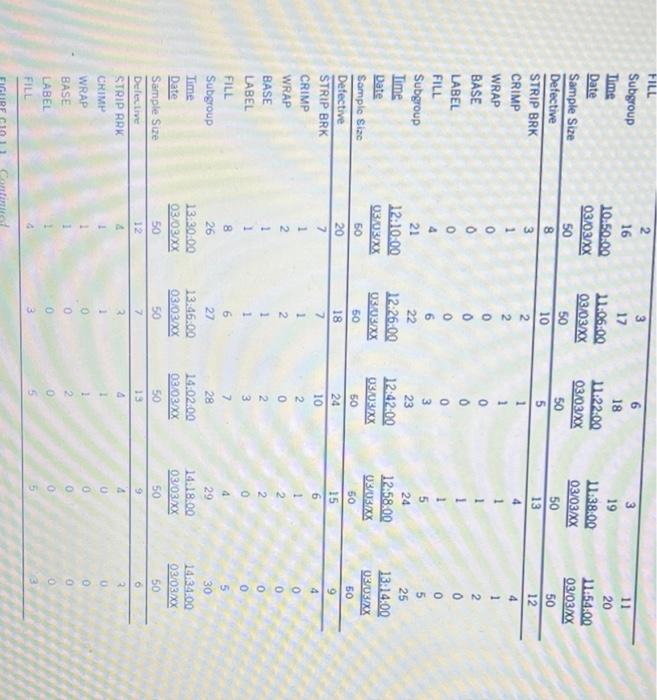

CASE STUDY 10.1 Attribute Control Charts: np Charts PART 1 At Fruits and Such, a local frozen fruit concentrate manufacturer, frozen orange juice concentrate is packed in 12-ounce cardboard cans. These cans are formed on a machine by spinning them from preprinted cardboard stock and attaching two metal lids, one for the top and one for the bottom. After filling, the container is carefully inspected. The inspectors test how well the strip to open the can operates. If a strip breaks, the can is considered nonconforming and unusable. Other packaging noncon formities include improper crimps holding the lids to the cardboard tube or poorly sealed lids. Fill rates are care- fully checked to ensure that the containers truly contain 12 ounces. Inspectors also check the cosmetics of the can. Incorrectly wrapped cans or crooked labels are considered nonconforming and unusable. An np chart for tracking unusable nonconformities needs to be established to track the level of nonconformi- ties produced on a daily basis. The first 30 subgroups of size n = $0 are found in Figure C10.1.1. PART NAME OJ can MACHINE: Spinner VARIABLE Scal 0700.00 03.03.2003 50 12 2 QA1600 303 50 15 5 02.32.00 0803/ 50 8 07.48.00 02.0/xx 50 10 08.04.09 03/03/XX 50 2 DEPT. Forming PART NO.:OJ-1 GROUP 1 Subgroup Time Date Sample Size Defective STRIP BRK CRIMP WRAP BASE LABEL FILL Subgroup TEM. Date Sample Sue Defective STRIP BRK CRIMP WRAP BASE LABEL FILL Subgroup NOON 8 ANONO 2 0 o 0 2 4 1 1 1 1 2 NOOOON18 6 08.35.00 20 50 08:20,00 DS_03 50 7 2 1 8 08:52:09 02.0 50 9 10 09:24.00 Q 50 10 16 4 09.08.00 02.02 50 14 5 . 1 1 2 0 2 0 1 1 SONON 5 6 12 o 4 11 092 OR 50 15 13 0.02.09 GELD 50 12 8 00 50 50 50 12 8 2 0 Samples Detective STRIP BRK CRIMP WRAP BASE LABEL 11 20 2. 16 10.50.00 03/03/XX 50 8 3 1 17 11:06:00 03/03/XX 50 10 2 2 18 1:22.00 03/03/ 50 5 1 1 3 19 1.38.00 03/03.XX 50 13 4 1 11.54:00 03/03/XX 50 12 4 1 0 2 NAOOO NOOOON WOO 23 12:42:00 003XX 21 12:10:00 03/ 0XX 50 20 7 1 2 FILL Subgroup Time Date Sample Size Detective STRIP BRK CRIMP WRAP BASE LABEL FILL Subgroup Time Date Sample Size Defective STRIP BRK CRIMP WRAP BASE LABEL FILL Subgroup Time Date Sample Size Delective STRIP RRK CRIMP WRAP BASE LABEL FILL 6 22 12:26,00 XX 50 18 7 1 2 1 5 24 1258,00 UX/XX 50 15 25 1344.00 03/03/XX 50 50 24 10 2 0 ONO 80OOOOO 1 1 1 1 2 3 6 27 29 8 26 13.30:00 03/03/XX 50 1345.00 03/03XX 50 7 28 14:02:00 03/03/XX 50 18.00 03/03.XX 50 30 1024 0,0 03/03/XX 50 2 13 12 4 3 . 0 0 ON--18 OOOCS 0 Cantik ASSIGNMENT Use the total number of defectives to create the np chart. How is the process currently performing? What is the pro- cess capability? While the np chart keeps track only of the number of nonconformities and not the type, Figure C10.1.1 reveals that the inspectors have also been keeping track of the types of nonconformities. CASE STUDY 10.1 Attribute Control Charts: np Charts PART 1 At Fruits and Such, a local frozen fruit concentrate manufacturer, frozen orange juice concentrate is packed in 12-ounce cardboard cans. These cans are formed on a machine by spinning them from preprinted cardboard stock and attaching two metal lids, one for the top and one for the bottom. After filling, the container is carefully inspected. The inspectors test how well the strip to open the can operates. If a strip breaks, the can is considered nonconforming and unusable. Other packaging noncon formities include improper crimps holding the lids to the cardboard tube or poorly sealed lids. Fill rates are care- fully checked to ensure that the containers truly contain 12 ounces. Inspectors also check the cosmetics of the can. Incorrectly wrapped cans or crooked labels are considered nonconforming and unusable. An np chart for tracking unusable nonconformities needs to be established to track the level of nonconformi- ties produced on a daily basis. The first 30 subgroups of size n = $0 are found in Figure C10.1.1. PART NAME OJ can MACHINE: Spinner VARIABLE Scal 0700.00 03.03.2003 50 12 2 QA1600 303 50 15 5 02.32.00 0803/ 50 8 07.48.00 02.0/xx 50 10 08.04.09 03/03/XX 50 2 DEPT. Forming PART NO.:OJ-1 GROUP 1 Subgroup Time Date Sample Size Defective STRIP BRK CRIMP WRAP BASE LABEL FILL Subgroup TEM. Date Sample Sue Defective STRIP BRK CRIMP WRAP BASE LABEL FILL Subgroup NOON 8 ANONO 2 0 o 0 2 4 1 1 1 1 2 NOOOON18 6 08.35.00 20 50 08:20,00 DS_03 50 7 2 1 8 08:52:09 02.0 50 9 10 09:24.00 Q 50 10 16 4 09.08.00 02.02 50 14 5 . 1 1 2 0 2 0 1 1 SONON 5 6 12 o 4 11 092 OR 50 15 13 0.02.09 GELD 50 12 8 00 50 50 50 12 8 2 0 Samples Detective STRIP BRK CRIMP WRAP BASE LABEL 11 20 2. 16 10.50.00 03/03/XX 50 8 3 1 17 11:06:00 03/03/XX 50 10 2 2 18 1:22.00 03/03/ 50 5 1 1 3 19 1.38.00 03/03.XX 50 13 4 1 11.54:00 03/03/XX 50 12 4 1 0 2 NAOOO NOOOON WOO 23 12:42:00 003XX 21 12:10:00 03/ 0XX 50 20 7 1 2 FILL Subgroup Time Date Sample Size Detective STRIP BRK CRIMP WRAP BASE LABEL FILL Subgroup Time Date Sample Size Defective STRIP BRK CRIMP WRAP BASE LABEL FILL Subgroup Time Date Sample Size Delective STRIP RRK CRIMP WRAP BASE LABEL FILL 6 22 12:26,00 XX 50 18 7 1 2 1 5 24 1258,00 UX/XX 50 15 25 1344.00 03/03/XX 50 50 24 10 2 0 ONO 80OOOOO 1 1 1 1 2 3 6 27 29 8 26 13.30:00 03/03/XX 50 1345.00 03/03XX 50 7 28 14:02:00 03/03/XX 50 18.00 03/03.XX 50 30 1024 0,0 03/03/XX 50 2 13 12 4 3 . 0 0 ON--18 OOOCS 0 Cantik ASSIGNMENT Use the total number of defectives to create the np chart. How is the process currently performing? What is the pro- cess capability? While the np chart keeps track only of the number of nonconformities and not the type, Figure C10.1.1 reveals that the inspectors have also been keeping track of the types of nonconformities

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock