Question: i need help creating a cpm schedule using the following information Immediately after the yforms have been own to the next level, installation of temporary

i need help creating a cpm schedule using the following information

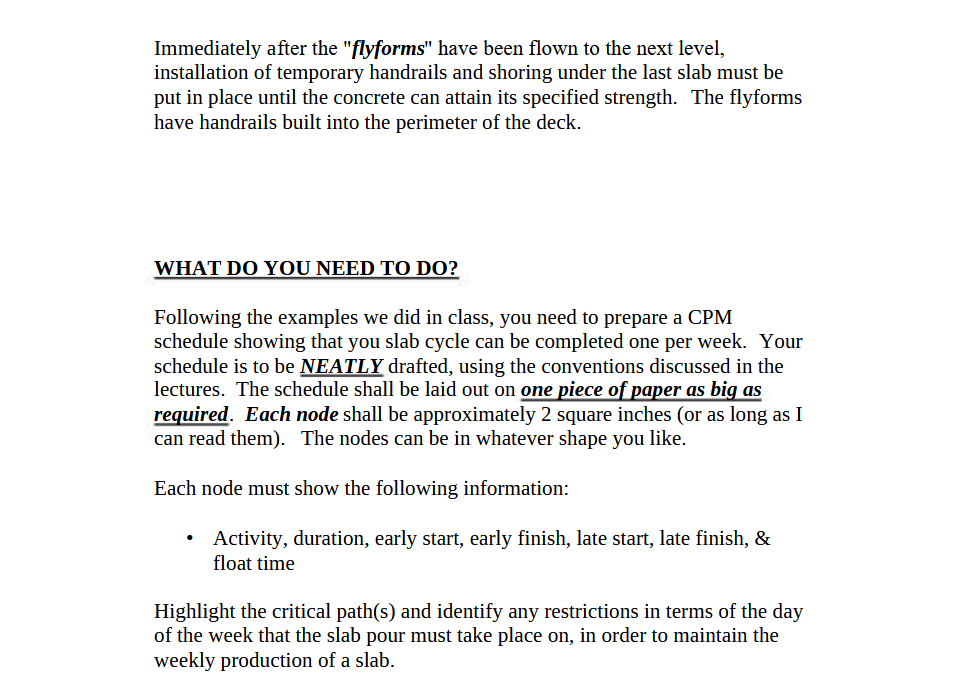

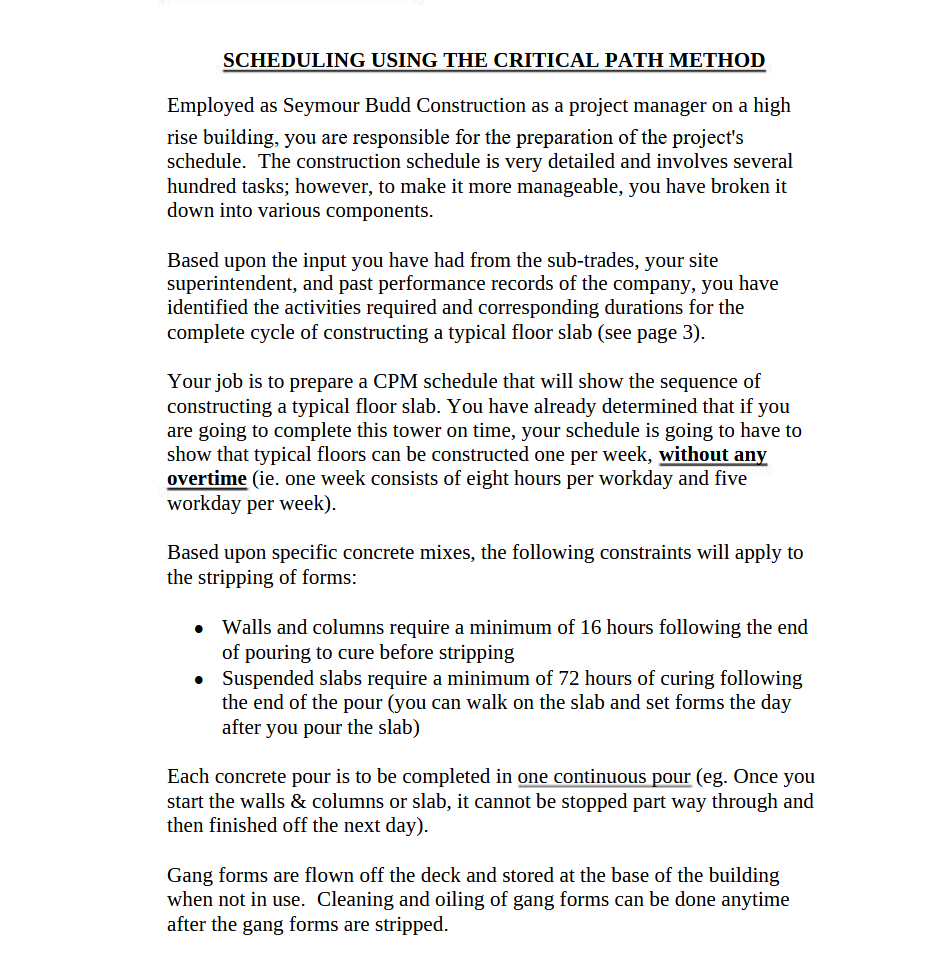

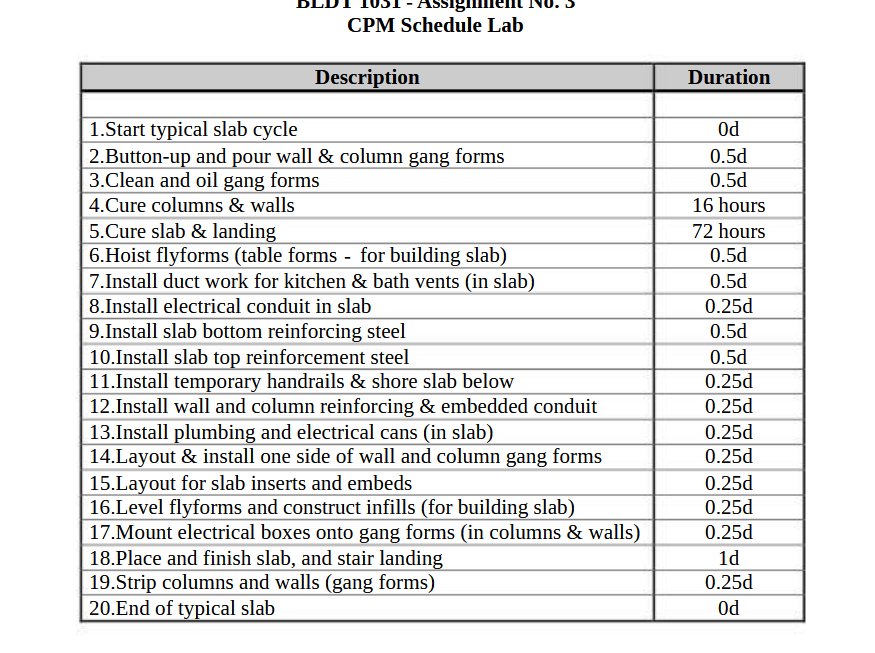

Immediately after the \"yforms\" have been own to the next level, installation of temporary handrails and shoring under the last slab must be put in place until the concrete can attain its specified strength. The yforms have handrails built into the perimeter of the deck. WHAT DO YOU NEED TO DO? Following the examples we did in class, you need to prepare a CPM schedule showing that you slab cycle can be completed one per week. Your schedule is to be NEATLY drafted, using the conventions discussed in the lectures. The schedule shall be laid out on one piece of paper as big as required. Each node shall be approximately 2 square inches (or as long as I can read them). The nodes can be in whatever shape you like. Each node must show the following information: - Activity, duration, early start, early finish, late start, late finish, 8: float time Highlight the critical path(s) and identify any restrictions in terms of the day of the week that the slab pour must take place on, in order to maintain the weekly production of a slab. SCHEDULING USING THE CRITICAL PATH METHOD Employed as Seymour Budd Construction as a project manager on a high rise building, you are responsible for the preparation of the project's schedule. The construction schedule is very detailed and involves several hundred tasks; however, to make it more manageable, you have broken it down into various components. Based upon the input you have had from the sub-trades, your site superintendent, and past performance records of the company, you have identified the activities required and corresponding durations for the complete cycle of constructing a typical oor slab (see page 3). Yourjob is to prepare a CPM schedule that will show the sequence of constructing a typical floor slab. You have already determined that if you are going to complete this tower on time, your schedule is going to have to show that typical floors can be constructed one per week, without any overtime (ie. one week consists of eight hours per workday and five workday per week). Based upon specific concrete mixes, the following constraints will apply to the stripping of forms: 0 Walls and columns require a minimum of 16 hours following the end of pouring to cure before stripping o Suspended slabs require a minimum of ?2 hours of curing following the end of the pour {you can walk on the slab and set forms the day after you pour the slab) Each concrete pour is to be completed in one continuous pour (e g. Once you start the walls 8: columns or slab, it cannot be stopped part way through and then finished off the next day). Gang forms are own off the deck and stored at the base of the building when not in use. Cleaning and oiling of gang forms can be done anytime after the gang forms are stripped. BL!\" 1 10.)]. - blglllllt'lll I'll. J (3PM Schedule Lab m 1.Start typical slab cycle 2.Button-up and pour wall 8: column gang forms 3.Clean and oil gang forms 4.Cnre columns 8: walls 513an slab 8: landing 6.Hoist flyforms (table forms - for building slab) T.lnstall duct work for kitchen 8: bath vents (in slab) 8.1nstall electrical conduit in slab 10.1nstall slab top reinforcement steel [15d 11.Install temporary handrails S: shore slab below 0.25d 12.Install wall and column reinforcing 8: embedded conduit 0.25d 13.Install plumbing and electrical cans (in slab) [L25d 14.Layout :3: install one side of wall and column gang forms 15.Layout for slab inserts and embeds 16.Level flyforms and construct infills (for building slab) 17.Mount electrical boxes onto gang forms (in columns 8: walls) 18.Place and finish slab, and stair landing 19.Strip columns and walls (gang forms) 20.End of typical slab

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts