Question: I need help finding the overhead cost per unit. Way Cool produces two different models of air conditioners. The company produces the mechanical systems in

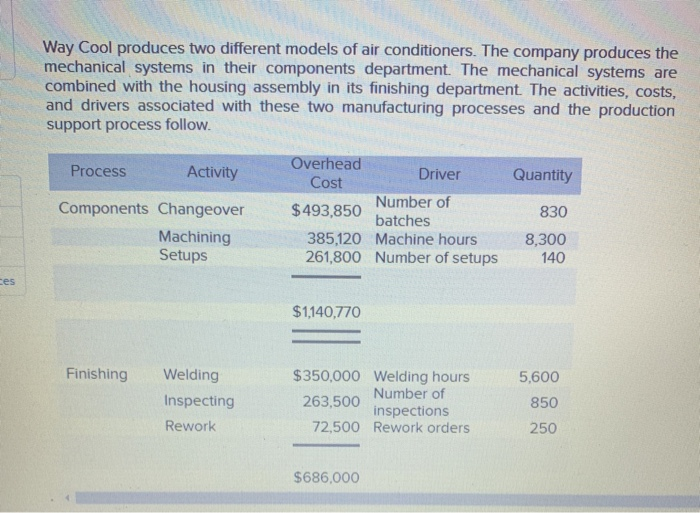

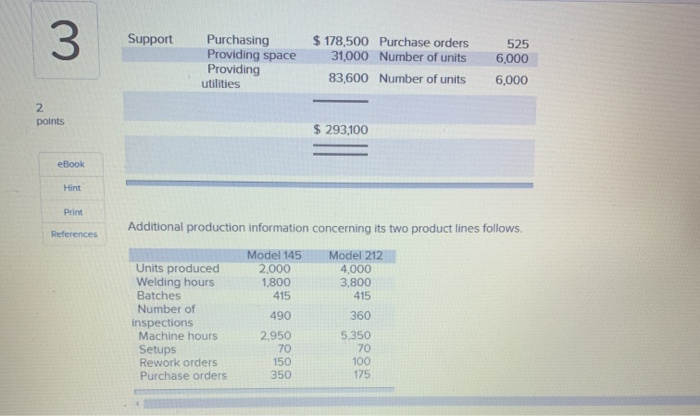

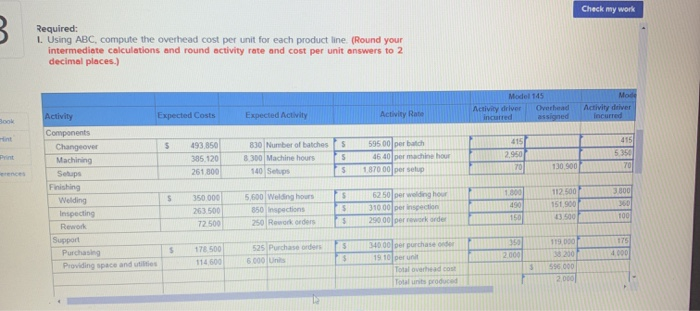

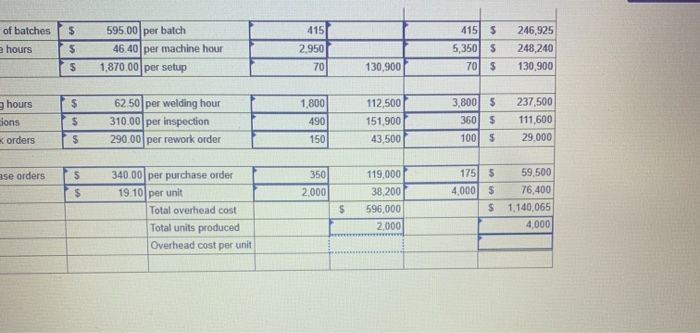

Way Cool produces two different models of air conditioners. The company produces the mechanical systems in their components department. The mechanical systems are combined with the housing assembly in its finishing department. The activities, costs, and drivers associated with these two manufacturing processes and the production support process follow. Overhead Process Activity Driver Quantity Cost $493,850 Number of batches Components Changeover 830 Machining Setups 385,120 261,800 8,300 140 Machine hours Number of setups es $1140,770 Finishing Welding $350,000 Welding hours 5,600 Number of 263,500 inspections Inspecting 850 Rework 72,500 Rework orders 250 $686,000 3 Support $178,500 Purchase orders 31,000 Number of units Purchasing Providing space Providing utilities 525 6,000 83,600 Number of units 6,000 2 points $293,100 eBook Hint Print Additional production information concerning its two product lines follows. References Model 145 2,000 Model 212 Units produced Welding hours Batches Number of 4,000 1,800 415 3,800 415 490 360 inspections Machine hours Setups Rework orders Purchase orders 5,350 70 100 175 2,950 70 150 350 415 S 595.00 per batch of batches S 415 246,925 5,350 S a hours 46.40 per machine hour 2,950 248,240 $ 1,870.00 per setup 70 $ 130,900 130,900 70 62.50 per welding hour 3,800 S 237,500 hours 1,800 112,500 360 S 111,600 ions 310.00 per inspection 290.00 per rework order 490 151,900 100 S 29,000 orders 150 43,500 175 S 59,500 119,000 ase orders 340.00 per purchase order 350 2,000 76,400 4,000 19.10 per unit 38,200 1,140,065 596,000 S Total overhead cost $ Total units produced 4,000 2,000 Overhead cost per unit

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts