Question: I need help solving the following problem or need some start. Please show as much work as possible so I can see where I am

I need help solving the following problem or need some start. Please show as much work as possible so I can see where I am going wrong.Thank-you

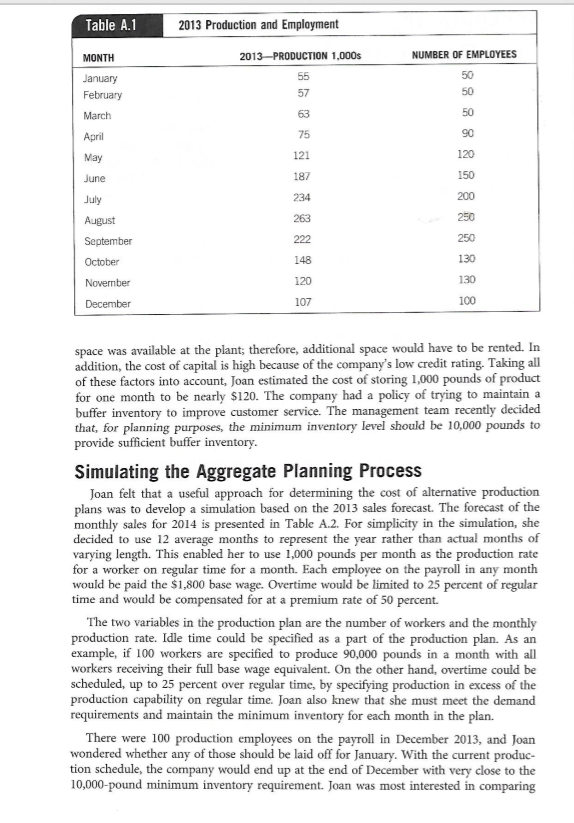

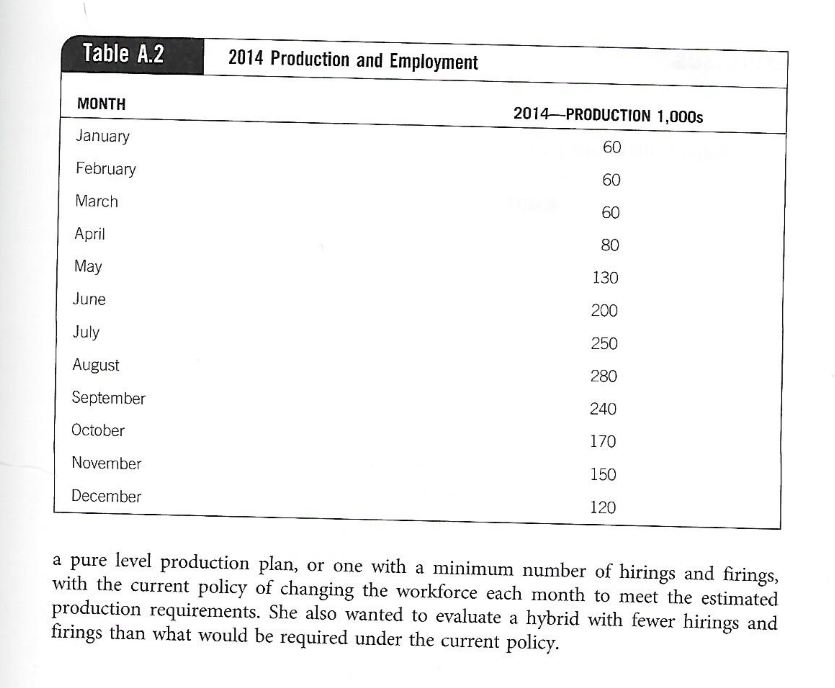

2013 Production and Employment MONTH 2013_ PRODUCTION 1. ODDS NUMBER OF EMPLOYEES January" 515 February 57 March . 50 April TE Way 121 120 June 187 150 July 2:34 200 AUGUST `Catember 22 2 250 LAB 130 MOVEITTHE` 1207 130 December 107 100 space was available at the plant ; therefore , additional space would have to be rented . In addition , the cost of capital is high because of the company's low credit rating . Taking all of these factors into account , Toan estimated the cost of storing 1, 1010 pounds of product for one month to be nearly $120 . The company had a policy of trying to maintain a buffer inventory to improve customer service . The management team recently decided that , for planning purposes , the minimum inventory level should he 10.010 pounds to provide sufficient buffer inventory . Simulating the Aggregate Planning Process Joan felt that a useful approach for determining the cast of alternative production plans was to develop a simulation based on the 2013 sales Forecast. The forecast of the monthly sales For 2014 is presented in Table A. 2. For simplicity in the simulation , she decided to use 12 average months to represent the year rather than actual months of carving length . This enabled her to use 1, 000 pounds per month as the production rate for a worker on regular time for a month . Each employee on the payroll in any month would be paid the $1, and base wage. Overtime would be limited to 25 percent of regular time and would be compensated for at a premium rate of 50 percent .` "The two variables in the production plan are the number of workers and the monthly production rate . Idle time could be specified as a part of the production plan _ As an example , it Lay workers are specified to produce 90.and pounds in a month with all workers receiving their full base wage equivalent . On the other hand , overtime could be scheduled , up to 25 percent over regular time , by specifying production in excess of the production capability on regular time Joan also knew that she must meet the demand requirements and maintain the minimum inventory for each month in the plan . There were 107 production employees on the payroll in December 2013 , and Joan wondered whether any of those should be laid off for January . With the current produc- tion schedule , the company would end up at the end of December with very close to the 10, and _ pound minimum inventory requirement. Joan was most interested in comparing*LE`le A` 2014 Production and Employment MONTH 2014 - PRODUCTION 1 , 0005 January" February March April May 130 June ZUD) July 250 AUGUST 280 September 240 October 170 November 150 December 120 a pure level production plan , or one with a minimum number of hirings and firings , with the current policy of changing the workforce each month to meet the estimated production requirements . She also wanted to evaluate a hybrid with fewer hirings and firings than what would be required under the current policy

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts