Question: I need help with questioning, and two; if you need more information, I will be able to provide it. those are the instructions ads/Case%20study. Northcutt%20Bikes.pdf

I need help with questioning, and two; if you need more information, I will be able to provide it.

those are the instructions

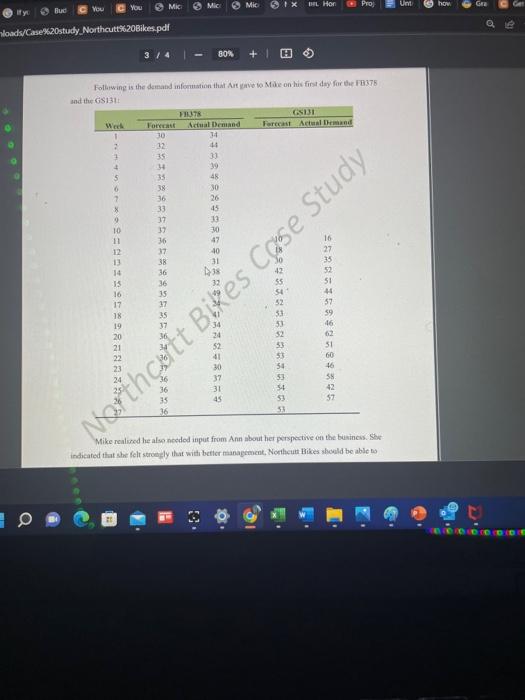

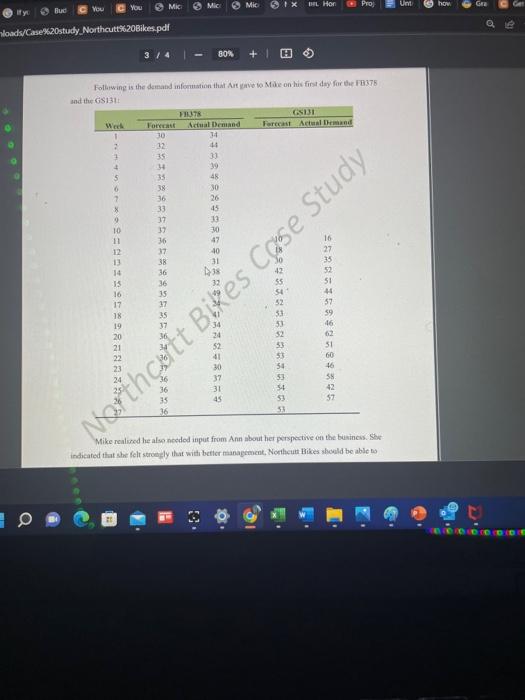

ads/Case%20study. Northcutt%20Bikes.pdf 1 / 4 80% + I O Northeuft Bikes: The Service Department Introduction Several years ago, Jan Northcutt, owner of Northcutt Bikes, recognized the need to organize a separate department to deal with service parts for the bikes her company makes Because the competitive strength of her company was developed around customer responsiveness and flexibility, she felt that creating a separate department focused exclusively on aftermarket service was critical in meeting that mission When she established the department, she named Ann Hill, one of her clerical workers at the time, to establish and manage the department. At first, the irtment occupied only a comer of the production warehouse, but now it has grown to occupy its own 100,000 square foot warehouse. The service business has also grown sigefficantly, and it now represents over 15% of the total revenue of Northcutt Bikes. The exclusiv mission of the service department is to provide parts (tires, seats, chains, etc.) many retail business that sell and service Northeutt Bikes While Ann has turned out to be a very manager and now holds the title of Director of Aftermarket Service), she still basic understanding of materials management To help her develop a more effective materials management program, she hired Mike Alexander, a recent graduate of an outstanding usiness management program at North Carolina State University, to fill the newly position of Materials Manager of Aftermarket service. The Current Situation During the process, Mike got the impression that there was a lot of opportunity for improvement thcott Bikes. It was only after he selected his starting date and requested some informe that he started to see the full extent of the challenges that lay ahead. His first day on really opened his eyes. One of the first items he had requested was a status report on inventory history and shipped orders. In response, the following note was on his desk the first day from the warchouse supervisor, Art Demming piese de We could not compile the Wory you requested as we keep no such records. There is just ity Bud C You You S Mic Mic Mici IX EL HOE PIC Unt how Gra ownloads/Case%20study. Northcutt%20Bikes.pdf 2 / 4 80% Mike decided to investigate the Albo the records were idee diffick down and comple, by the end of his second week, bedobbi fly good picture of the wat based on an investigation of 100 paits selectat a random Hearned, for example, that although there was an average of over 70 days worth of inventory leverage aventory, the late for customer ordees was less than 80% of the item request Inventory, the remaining onders were backordered. Unfortunately, the maily viewed service partage and would take their business clewhere in parts were not vilable from Northcuttakes What really was when those businesses sometimes caled their entire order for parts and placed it with other parts supplier The iconicon was that while there was plenty of inventory overall the timing and quantities were placed. Increasing the inventory did not appear to be the answer, not only become a barge amount was already being held bewuse the space in the warehouse built the two years) increased from being 49 utilized just after they moved in to its presentation of over 95% Mike decided to this may development of solutions on the westems for which Art had already provided dem dhustory. He felt that if he cool analyze and correct any problems with those two parts could expand the analysis to most of the other. The two item on which he had history concentrated his initial analysis were the FR37 Fender lacket and the GSI31 Gear Sprock North Bikes purchase the 18:37 from a Brature. The lead times constant at three weeks, and the estimated cost of purchase order for these parts 535 per order. Currently North Bikesses an onder losire of 120 for the FH378 buys the item for 55 piece The GSII part, on the other hand, in a newer product only recently being offered. A machine shop in Nashville, Tennessee, produces the part for Northet Biker, and it gives Northult Bikes a fairly reliable six week lead time. The cost of placing an order with the machine shop is only about $15.d currently Northet Bikes onders 850 parts at a time Northet Bikes buys the item for $10.75 agitan YOU Mic S Mic Mic SIX DHL HON Vou Unt Pro Choy GE fyBus Q loads/Case20study, Northcut19620Bikes.pdf 314 80N Following is the demand information that Are to Me on his first day for the F8375 and the GSI31 PUR (5131 Week FORNO Actual Demand Ferra Actual Demand 1 30 34 2 12 44 1 35 33 + 39 5 48 0 38 30 7 36 26 8 33 45 9 37 13 10 37 30 1 36 47 12 37 40 27 13 38 31 35 14 36 52 15 36 51 16 15 54 46 17 37 57 18 31 59 19 53 46 20 32 02 21 52 33 51 22 41 53 60 30 54 46 37 53 38 31 54 42 35 45 53 57 16 53 * Marthertt Bikes Case Study Mike realised he also needed input from Ann about her perspective on the business. She indicated that she felt strongly that with better management, Northcuit Bikes should be able to DDDDDD Pro Unt how Gra POL. Hor 1x Mic 3 MK 9 Mic YOU ify Cou Downloads/Case%20study Northcutt20Bikes.pdf 4/4 - 80% dock 31 14 30 53 2 57 15 Mart Mike dhe needed it from Annshot her penpective on the hip. She indicated that the feestdly that with her management. Nohut Rakeshold be able use the editing schoose for years to come, even with the anticipated within buri. Carbowever, the views the situation is because we are hunting them with Investy It's costing a lot of profit, yer our service level is very poor, less than 0% Tilike to see itin 9 or better service level without back orders, yet we need to be able to do that with a reduction in totality. What do you, Me? Can we do better Questions 1. the waiable data to develop inventory policies Corder quantities and reorder po for the FR378 and mechat the holding cost 20% of the unit price 2. Compare the inventory conted with your order quantities with the of the current order quantities. What can you can 3. Do you think the lost customer cald be included as a cost of cry?why! Flow would chance de policies you exted in 019 e sua Documents included in this Case Analysis Northcutt Bike Case Instruction Northcutt Bike Case . Learning Objectives Understand the economic order quantity (EOQ) and reorder point (RP) for the continuous review system Understand how inventory decisions affect other areas of the supply chain Case Analysis Questions: Use the available data to develop inventory policies (order quantities and reorder points) for the FB378 and GS131. Assume that the holding cost is 20% of the unit price. (25 points!!) Compare the inventory costs associated with your suggested order quantities with those of the current order quantities. What can you conclude? (25 points) Do you think the lost customer sales should be included as a cost of inventory? Why? How would such an inclusion impact the ordering policies you established in Q1? (25 points) . Instructor Note: The Northcutt Bike case make you familiarize with the relationships between economic order quantity, service level, reorder point, and total cost. As you work through the case, you will discover the positive and negative effects that changing order quantity and reorder point can have on total cost. You will also gain experences for the benefits of ordering the optimal size in an environment of variable demand and have the opportunity to analyze the costs and benefits of a capital expenditure proposal intended to reduce order quantity, You can find your team member in Brightspace (Communication->Groups) To carn full points for each question, you need to make the correct calculation and fully explain each question. The instructor has no expectation on the length of your analysis, but to earn full points, you need fully explain each question. Submission The due date of this case is 11:59pm, May 3, 2022 Your team need to submit your case analysis through Brightspace. In your document, you need to address the case analysis questions listed above. Case analysis tips at the end of this instruction provides some tips to prepare the answers, The instructor does not accept email submission. In order to earn full points of Q1 and 02. you need to show the detailed calculation. Case Analysis Tips: For question 1, you need to calculate EOQ and reorder point. Here are some hints for the parameters (take FB378 for example): . . . . This case is worth 100 points in total. The points listed at the end of each question indicate the grading rubriek 0 Annual demand: actual demand is given from week 1 to week 26, you can first calculate average weekly demand based on the first 26 weeks demand. Next, you use average weekly demand times 52 (Each year has 52 weeks in total) and this is annual demand. o Average demand during lead time-average weekly demand of the first 26 weeks o Standard deviation of demand for FB 378 is 7.91 and for GS131 is 12.78. For question 2, you first need to calculate the total cost with the current order quantity, and then calculate the total cost if you order EOQ. Next, you compare those two total costs and see how much you can save

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock