Question: i need numbers 1 & 2 please 16.1 carol cagle has a repetitive manufacturing plant. the plant has an average inventory turnover of only 12

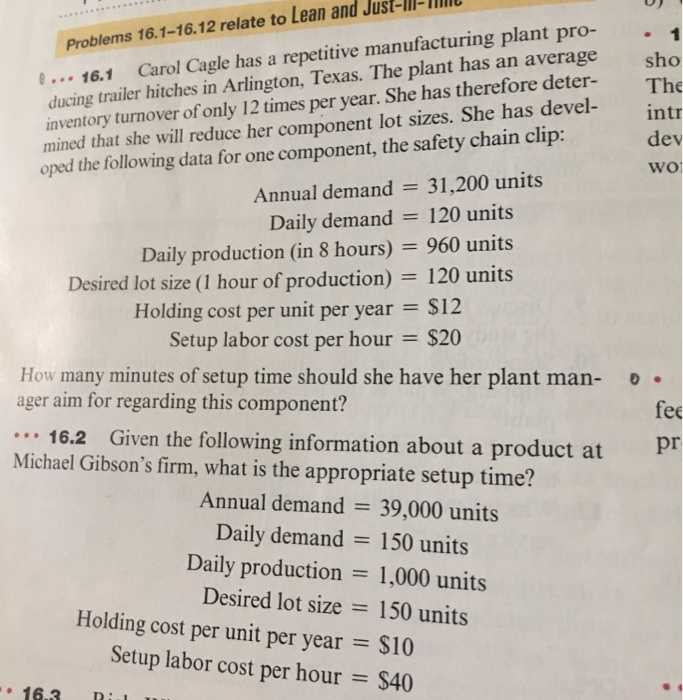

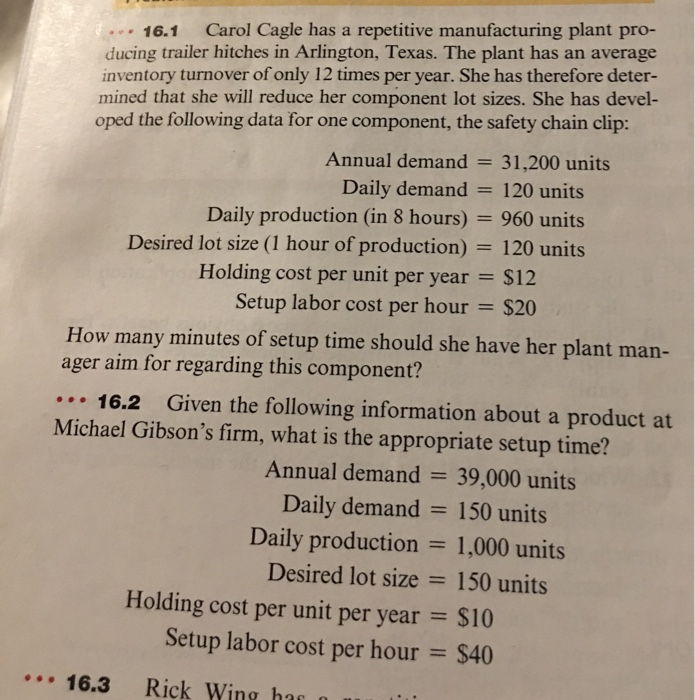

Problems 16.1-16.12 relate to Lean and Just-III-III sho The intr 2... 16.1 Carol Cagle has a repetitive manufacturing plant pro- ducing trailer hitches in Arlington, Texas. The plant has an average inventory turnover of only 12 times per year. She has therefore deter- mined that she will reduce her component lot sizes. She has devel- oped the following data for one component, the safety chain clip: dev wo Annual demand = 31,200 units Daily demand = 120 units Daily production (in 8 hours) = 960 units Desired lot size (1 hour of production) = 120 units Holding cost per unit per year = $12 Setup labor cost per hour = $20 D. fee pr How many minutes of setup time should she have her plant man- ager aim for regarding this component? ... 16.2 Given the following information about a product at Michael Gibson's firm, what is the appropriate setup time? Annual demand = 39,000 units Daily demand = 150 units Daily production = 1,000 units Desired lot size = 150 units Holding cost per unit per year = $10 Setup labor cost per hour = $40 16.3 1:1 T... 16.1 Carol Cagle has a repetitive manufacturing plant pro- ducing trailer hitches in Arlington, Texas. The plant has an average inventory turnover of only 12 times per year. She has therefore deter- mined that she will reduce her component lot sizes. She has devel- oped the following data for one component, the safety chain clip: Annual demand = 31,200 units Daily demand = 120 units Daily production (in 8 hours) = 960 units Desired lot size (1 hour of production) = 120 units Holding cost per unit per year = $12 Setup labor cost per hour = $20 How many minutes of setup time should she have her plant man- ager aim for regarding this component? ... 16.2 Given the following information about a product at Michael Gibson's firm, what is the appropriate setup time? Annual demand = 39,000 units Daily demand = 150 units Daily production = 1,000 units Desired lot size = 150 units Holding cost per unit per year = $10 Setup labor cost per hour = $40 ... 16.3 Rick Wing har

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts