Question: I NEED PROBLEM 42, PROBLEM 41 IS JUST THERE FOR REFERENCE! THANK YOU 41. CalcIt produces a line of calculators. One model, IT53, is a

I NEED PROBLEM 42, PROBLEM 41 IS JUST THERE FOR REFERENCE! THANK YOU

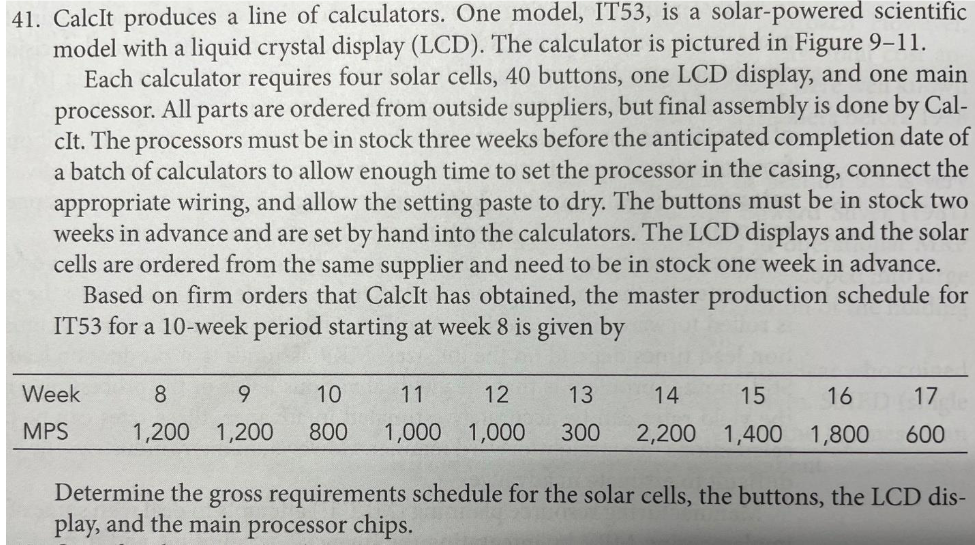

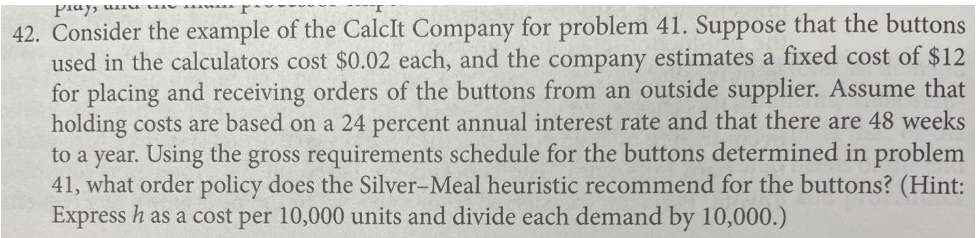

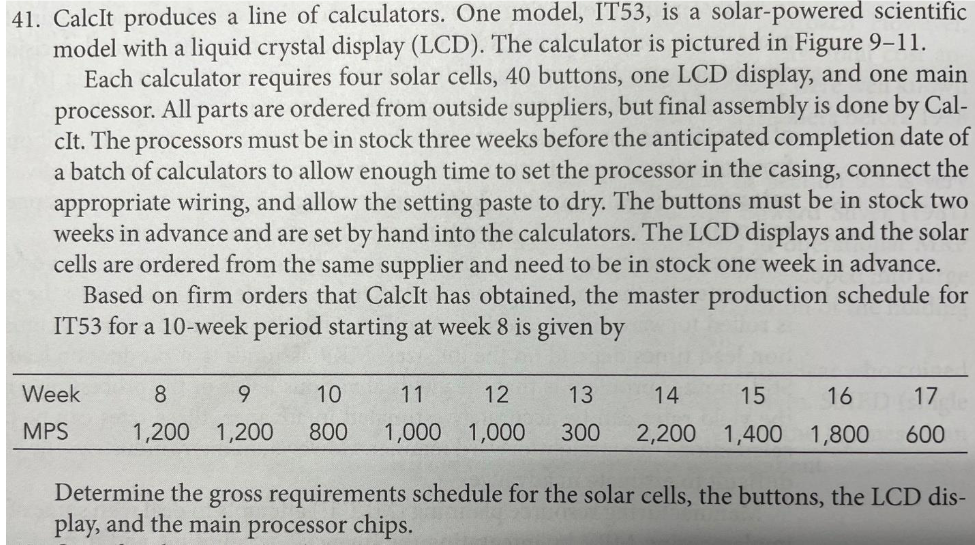

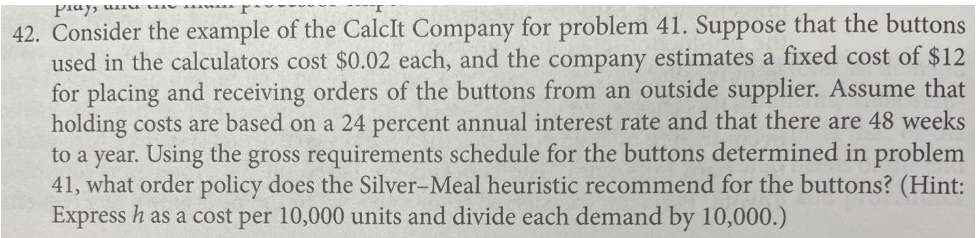

41. CalcIt produces a line of calculators. One model, IT53, is a solar-powered scientific model with a liquid crystal display (LCD). The calculator is pictured in Figure 9-11. Each calculator requires four solar cells, 40 buttons, one LCD display, and one main processor. All parts are ordered from outside suppliers, but final assembly is done by CalcIt. The processors must be in stock three weeks before the anticipated completion date of a batch of calculators to allow enough time to set the processor in the casing, connect the appropriate wiring, and allow the setting paste to dry. The buttons must be in stock two weeks in advance and are set by hand into the calculators. The LCD displays and the solar cells are ordered from the same supplier and need to be in stock one week in advance. Based on firm orders that CalcIt has obtained, the master production schedule for IT53 for a 10-week period starting at week 8 is given by \begin{tabular}{l} W \\ \hline MF \end{tabular} Determine the gross requirements schedule for the solar cells, the buttons, the LCD display, and the main processor chips. 42. Consider the example of the CalcIt Company for problem 41 . Suppose that the buttons used in the calculators cost $0.02 each, and the company estimates a fixed cost of $12 for placing and receiving orders of the buttons from an outside supplier. Assume that holding costs are based on a 24 percent annual interest rate and that there are 48 weeks to a year. Using the gross requirements schedule for the buttons determined in problem 41, what order policy does the Silver-Meal heuristic recommend for the buttons? (Hint: Express h as a cost per 10,000 units and divide each demand by 10,000 .) 41. CalcIt produces a line of calculators. One model, IT53, is a solar-powered scientific model with a liquid crystal display (LCD). The calculator is pictured in Figure 9-11. Each calculator requires four solar cells, 40 buttons, one LCD display, and one main processor. All parts are ordered from outside suppliers, but final assembly is done by CalcIt. The processors must be in stock three weeks before the anticipated completion date of a batch of calculators to allow enough time to set the processor in the casing, connect the appropriate wiring, and allow the setting paste to dry. The buttons must be in stock two weeks in advance and are set by hand into the calculators. The LCD displays and the solar cells are ordered from the same supplier and need to be in stock one week in advance. Based on firm orders that CalcIt has obtained, the master production schedule for IT53 for a 10-week period starting at week 8 is given by \begin{tabular}{l} W \\ \hline MF \end{tabular} Determine the gross requirements schedule for the solar cells, the buttons, the LCD display, and the main processor chips. 42. Consider the example of the CalcIt Company for problem 41 . Suppose that the buttons used in the calculators cost $0.02 each, and the company estimates a fixed cost of $12 for placing and receiving orders of the buttons from an outside supplier. Assume that holding costs are based on a 24 percent annual interest rate and that there are 48 weeks to a year. Using the gross requirements schedule for the buttons determined in problem 41, what order policy does the Silver-Meal heuristic recommend for the buttons? (Hint: Express h as a cost per 10,000 units and divide each demand by 10,000 .)