Question: 1) The concrete sections of a certain superhighway are designed to have a length of 25.0 m. The sections are poured and cured at

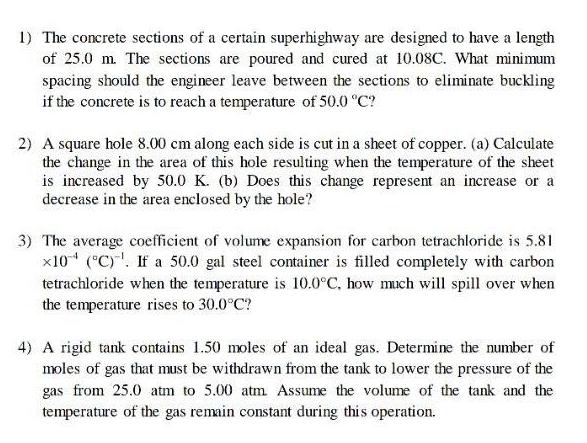

1) The concrete sections of a certain superhighway are designed to have a length of 25.0 m. The sections are poured and cured at 10.08C. What minimum spacing should the engineer leave between the sections to eliminate buckling if the concrete is to reach a temperature of 50.0 C? 2) A square hole 8.00 cm along each side is cut in a sheet of copper. (a) Calculate the change in the area of this hole resulting when the temperature of the sheet is increased by 50.0 K. (b) Does this change represent an increase or a decrease in the area enclosed by the hole? 3) The average coefficient of volume expansion for carbon tetrachloride is 5.81 x10 (C). If a 50.0 gal steel container is filled completely with carbon tetrachloride when the temperature is 10.0C, how much will spill over when the temperature rises to 30.0C? 4) A rigid tank contains 1.50 moles of an ideal gas. Determine the number of moles of gas that must be withdrawn from the tank to lower the pressure of the gas from 25.0 atm to 5.00 atm. Assume the volume of the tank and the temperature of the gas remain constant during this operation.

Step by Step Solution

3.36 Rating (149 Votes )

There are 3 Steps involved in it

ution Given L25M Page from literature for concrete the coefficient of thermal e... View full answer

Get step-by-step solutions from verified subject matter experts