Question: i need the model TE 33150 Operations Research Lab Lab 7 Instructions: Model the following problem and submit your LP on Monday 11/5/2020 at 11:55

i need the model

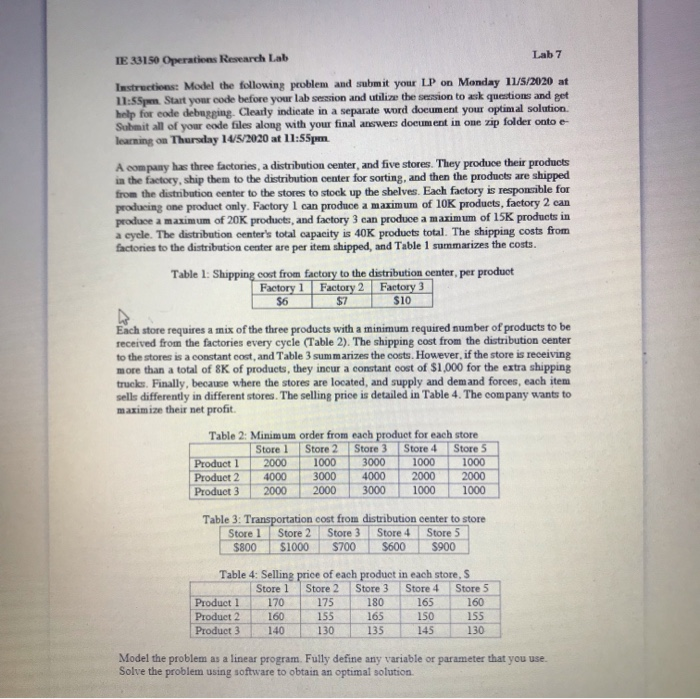

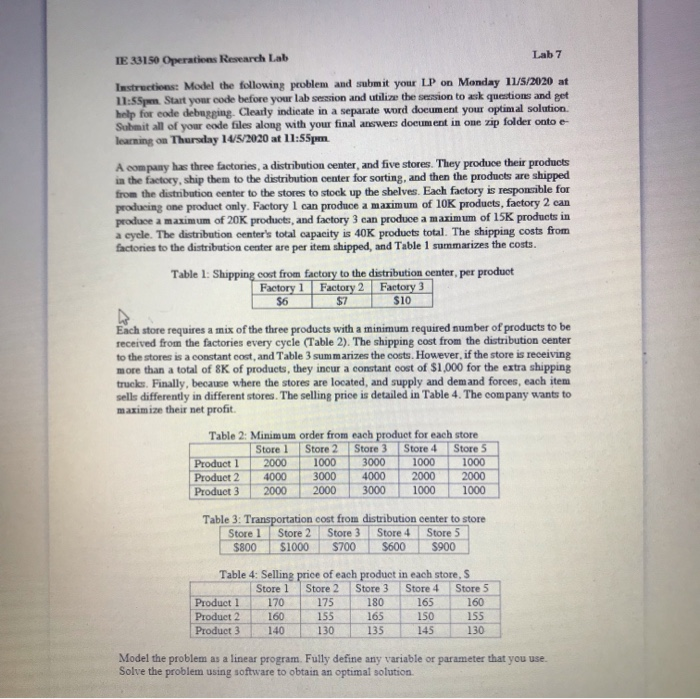

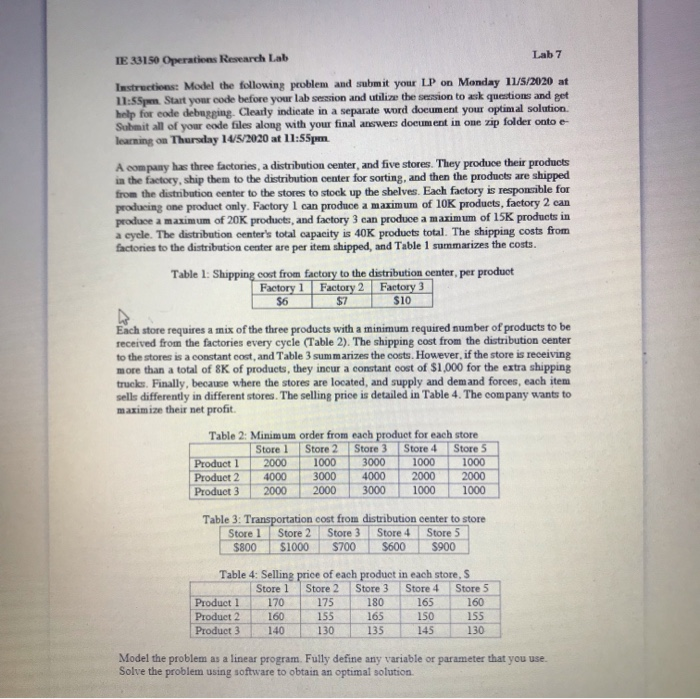

TE 33150 Operations Research Lab Lab 7 Instructions: Model the following problem and submit your LP on Monday 11/5/2020 at 11:55 Start your code before your lab session and utilize the session to ask questions and get help for code debugging. Clearly indicate in a separate word document your optimal solution Submit all of your code files along with your final answers document in one zip folder onto - learning on Thursday 145/2020 at 11:55pm A company has three factories, a distribution center and five stores. They produce their products in the factory, ship them to the distribution center for sorting, and then the products are shipped from the distribution center to the stores to stock up the shelves. Each factory is responsible for producing one product only. Factory I can produce a maximum of 10K products, factory 2 can produce a maximum of 20K products, and factory 3 can produce a maximum of 15K products in a cycle. The distribution center's total capacity is 40K produets total. The shipping costs from factories to the distribution center are per item shipped, and Table 1 summarizes the costs. Table 1: Shipping cost from factory to the distribution center, per produot Factory 1 Factory 2 Factory 3 $10 $6 Each store requires a mix of the three products with a minimum required number of products to be received from the factories every cycle (Table 2). The shipping cost from the distribution center to the stores is a constant cost, and Table 3 summarizes the costs. However, if the store is receiving more than a total of 8K of products, they incur a constant cost of $1,000 for the extra shipping trucks. Finally, because where the stores are located and supply and demand forces, each item sells differently in different stores. The selling price is detailed in Table 4. The company wants to maximize their net profit Table 2: Minimum order from each product for each store Store 1 Store 2 Store 3 Store 4 Stores Product 1 2000 1000 3 000 1000 1000 Product 2 4000 3000 4000 2000 2000 Product 3 2000 2000 3000 1000 1000 Table 3: Transportation cost from distribution center to store Store 1 Store 2 Store 3 Store 4 Store 5 $800 $1000 $700 $600 9900 Table 4: Selling price of each product in each store, S Store 1 Store 2 Store 3 Store 4 Store 5 Product 1 170 175 180 165 160 Product 2 160 155 165 150 155 Product 3 140 130 135 145 130 Model the problem as a linear program. Fully define any variable or parameter that you use. Solve the problem using software to obtain an optimal solution TE 33150 Operations Research Lab Lab 7 Instructions: Model the following problem and submit your LP on Monday 11/5/2020 at 11:55 Start your code before your lab session and utilize the session to ask questions and get help for code debugging. Clearly indicate in a separate word document your optimal solution Submit all of your code files along with your final answers document in one zip folder onto - learning on Thursday 145/2020 at 11:55pm A company has three factories, a distribution center and five stores. They produce their products in the factory, ship them to the distribution center for sorting, and then the products are shipped from the distribution center to the stores to stock up the shelves. Each factory is responsible for producing one product only. Factory I can produce a maximum of 10K products, factory 2 can produce a maximum of 20K products, and factory 3 can produce a maximum of 15K products in a cycle. The distribution center's total capacity is 40K produets total. The shipping costs from factories to the distribution center are per item shipped, and Table 1 summarizes the costs. Table 1: Shipping cost from factory to the distribution center, per produot Factory 1 Factory 2 Factory 3 $10 $6 Each store requires a mix of the three products with a minimum required number of products to be received from the factories every cycle (Table 2). The shipping cost from the distribution center to the stores is a constant cost, and Table 3 summarizes the costs. However, if the store is receiving more than a total of 8K of products, they incur a constant cost of $1,000 for the extra shipping trucks. Finally, because where the stores are located and supply and demand forces, each item sells differently in different stores. The selling price is detailed in Table 4. The company wants to maximize their net profit Table 2: Minimum order from each product for each store Store 1 Store 2 Store 3 Store 4 Stores Product 1 2000 1000 3 000 1000 1000 Product 2 4000 3000 4000 2000 2000 Product 3 2000 2000 3000 1000 1000 Table 3: Transportation cost from distribution center to store Store 1 Store 2 Store 3 Store 4 Store 5 $800 $1000 $700 $600 9900 Table 4: Selling price of each product in each store, S Store 1 Store 2 Store 3 Store 4 Store 5 Product 1 170 175 180 165 160 Product 2 160 155 165 150 155 Product 3 140 130 135 145 130 Model the problem as a linear program. Fully define any variable or parameter that you use. Solve the problem using software to obtain an optimal solution