Question: I need these paragraphs a b and c answer Productivity and Work Study 1.1. Introduction A significant proportion of the Indian population is still struggling

I need these paragraphs a b and c answer

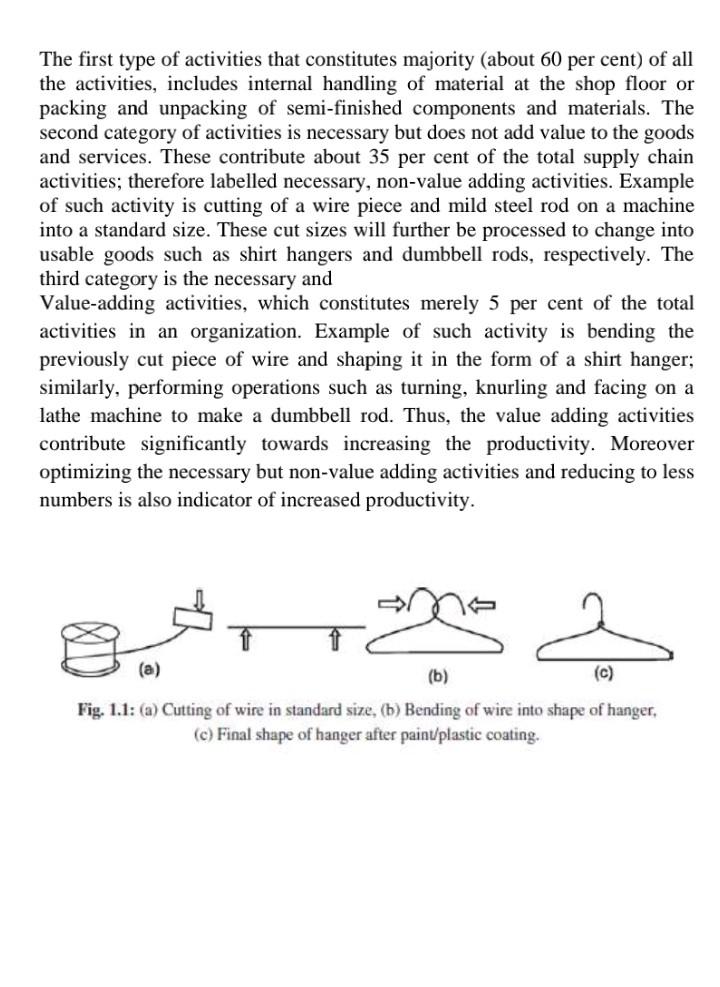

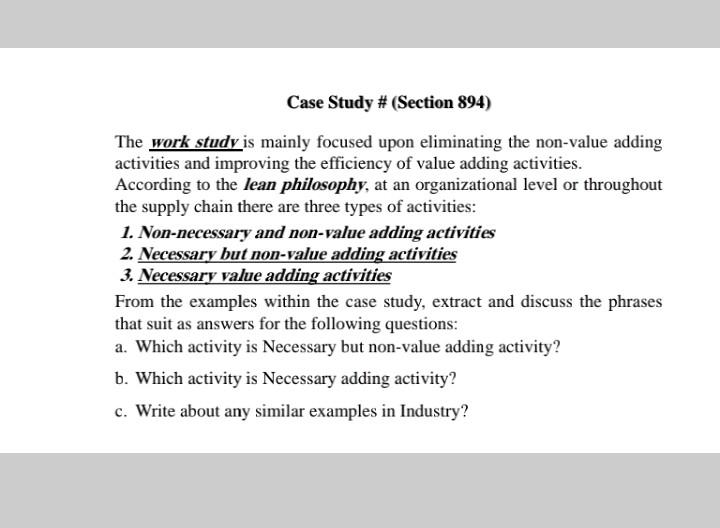

Productivity and Work Study 1.1. Introduction A significant proportion of the Indian population is still struggling for its basic needs: food, shelter, clothes, security and health services. A nation can only raise the level of satisfaction with respect to these basic needs only if the return from resources is maximized or the productivity is improved. Then, the economy will grow and help provide a better quality of life. Productivity at an enterprise is assessed in terms of output of a production variable per unit of input. Fundamentally, it is used to measure the output of resources such as manpower, machinery, materials and money, in producing goods and services or commodities to produce income or profitability. There are ample examples of Japanese manufacturers increasing their productivity, after the Second World War when they faced the dilemma of vast shortage of material and human resources. The problem of Japanese manufacturers was entirely different from their Western counterparts. Later, in the mid1940s, it was recognized by the president of Toyota Motor Company that American companies were outperforming them by a factor of ten. Therefore, in order to make a move towards rapid movement, Japanese leaders, such as Toyota, Shingo and Ohno devised a new process-oriented approach that is known as the 'Toyota Production System or Lean Manufacturing'. The main objective of this approach is to reduce wastes, which in Japanese terms is called 'Muda' and maximizing the activities that add value to the good or services in the customer's perspective. The term value can be attributed to anything in a product or service for which the customer is willing and ready to pay. The value addition in goods and services will increase the overall profitability of system, company or whole supply chain. According to the lean philosophy, at an organizational level or throughout the supply chain there are three types of activities: 1. Non-necessary and non-value adding activities 2. Necessary but non-value adding activities The first type of activities that constitutes majority (about 60 per cent) of all the activities, includes internal handling of material at the shop floor or packing and unpacking of semi-finished components and materials. The second category of activities is necessary but does not add value to the goods and services. These contribute about 35 per cent of the total supply chain activities; therefore labelled necessary, non-value adding activities. Example of such activity is cutting of a wire piece and mild steel rod on a machine into a standard size. These cut sizes will further be processed to change into usable goods such as shirt hangers and dumbbell rods, respectively. The third category is the necessary and Value-adding activities, which constitutes merely 5 per cent of the total activities in an organization. Example of such activity is bending the previously cut piece of wire and shaping it in the form of a shirt hanger; similarly, performing operations such as turning, knurling and facing on a lathe machine to make a dumbbell rod. Thus, the value adding activities contribute significantly towards increasing the productivity. Moreover optimizing the necessary but non-value adding activities and reducing to less numbers is also indicator of increased productivity. Fig. 1.1: (a) Cutting of wire in standard size, (b) Bending of wire into shape of hanger, (c) Final shape of hanger after paint/plastic coating. In addition to the above example, there is a case of one small scale foundry unit, which produces a family of hydraulic valves. The manager of the firm was looking after all the operations starting from moulding, pouring, trimming, chipping/chiseling, grinding, etc. The manager observed that the productivity of the firm was lower due to bottleneck at a workstation where the worker was removing the extra metal from the parting line of the casting by using chisel and hammer tools. The manager was much concerned to increase the productivity of that particular workstation, so that the overall productivity could be improved. So, he started looking for better and efficient tools (than the chisel and hammer), so that the bottleneck can be removed. This is one good example of non-necessary and non-value adding activity. The manager hired a consultant and asked him for designing better tools or devise new method so that efficiency of the worker can be increased. The manager took the consultant to the live work place; and after that the consultant immediately said that there was no need to design any tools; in fact, there was hardly any need of this operation even. Being surprised the manager asked for the reason. The consultant explained that the actual problem was not due to the tools or efficiency of the workers, but somewhere else, i.e., due to the loose clamping of moulding boxes (cope and drag), the molten metal leaked out at the parting line between the upper and lower moulds. Therefore, before pouring the molten metal into the mould, there was a need to assure that the side clamps were tightly fastened, and if needed extra weight be used so that when the molten metal was poured, the upper half of the mould would not be lifted due to the pressure of the molten metal. Now, the activities like removing the extra metal at the parting line is unnecessary and non-value adding; however, clamping of the moulding boxes is necessary but non-value adding activity. Therefore, the higher productivity is the outcome of value adding activities. The work study is mainly focused upon eliminating the non-value adding activities and improving the efficiency of value adding activities. Nowadays, most of the supply chains or the value chains are focused upon eliminating the nonnecessary and non-value adding activities, and optimizing value adding activities. One of the most important reasons for the decline of an enterprise or a supply chain is low productivity. Failure to achieve the targeted level of productivity leads to the higher cost per unit, hence higher prices and low competitiveness in the market. In the current scenario of a competitive world, many companies are striving to maintain the competiveness in the market. The productivity improvement at the local level cannot solely increase the productivity and profitability of a supply chain. Thus, it is very important to device a competitive strategy that enables not only an individual stage (enterprise) but also the whole supply chain to improve the productivity and profitability. Case Study \# (Section 894) The work studv is mainly focused upon eliminating the non-value adding activities and improving the efficiency of value adding activities. According to the lean philosophy, at an organizational level or throughout the supply chain there are three types of activities: 1. Non-necessary and non-value adding activities 2. Necessary but non-value adding activities 3. Necessary value adding activities From the examples within the case study, extract and discuss the phrases that suit as answers for the following questions: a. Which activity is Necessary but non-value adding activity? b. Which activity is Necessary adding activity? c. Write about any similar examples in Industry

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts