Question: I only need Question 2, It needs to be done in a Gant Chart and im very confused. Please help!! I'm only having troubles doing

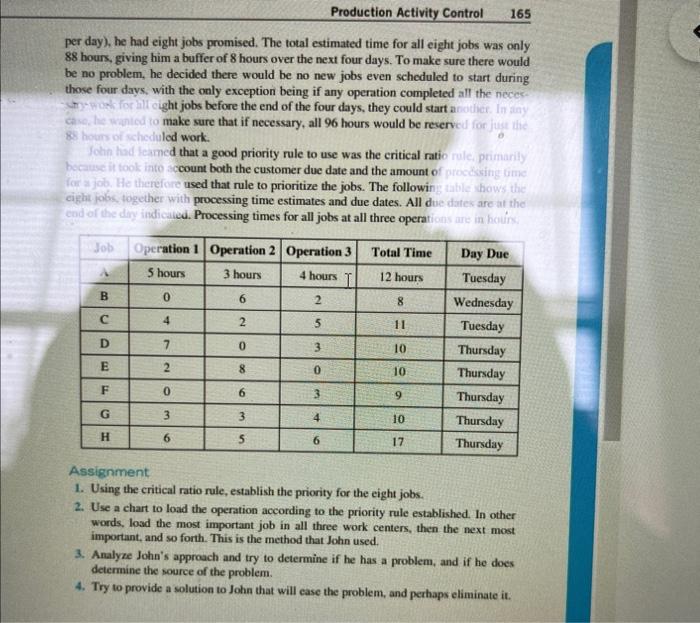

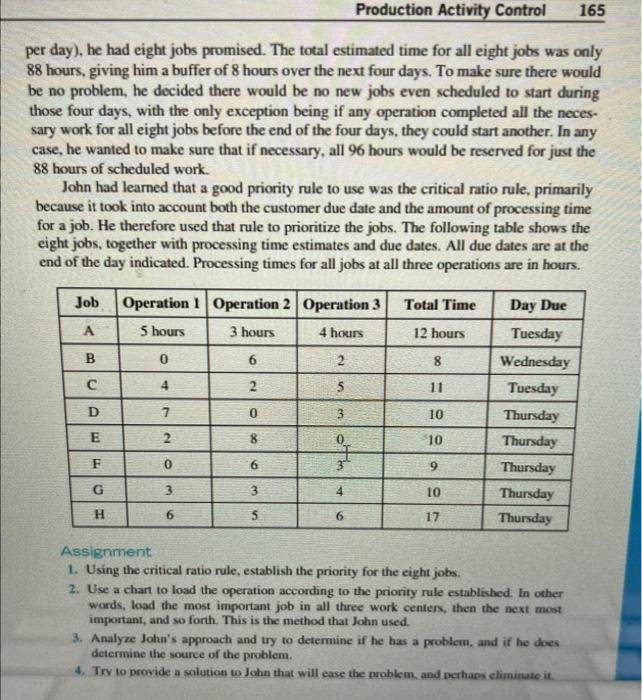

per day), he had eight jobs promised. The total estimated time for all eight jobs was only 88 hours, giving him a buffer of 8 hours over the next four days. To make sure there would be no problem, he decided there would be no new jobs even scheduled to start during those four days, with the only exception being if any operation completed all the neces- hy-workifior all eight jobs before the end of the four days, they could start anditice. In any Cas. hours of whechedulod work. Jokin had leamed that a good priority rule to use was the critical ratio rule primarily because in took into account both the customer due date and the amount of prockssing timest for a job. Ho therefore used that rule to prioritize the jobs. The followin cight jobs, together with processing time estimates and due dates. All due dates are at the cod of the diny indicaied. Processing times for all jobs at all three operations are in haulin Assignment 1. Using the critical ratio rule, establish the priority for the eight jobs. 2. Use a chart to load the operation according to the priority rule established. In other words, load the most important job in all three work centers, then the next most important, and so forth. This is the method that John used. 3. Analyze John's approach and try to determine if he has a problem, and if he does determine the source of the problem. 4. Try to provide a solution to John that will case the problem, and perhaps eliminate it. Ig been recently promoted from lead printer. While he felt very comfortable with his knowedge and success in the printing business, this managerial position was starting to wear on him. He was determined not to let it get him down, however, as he felt he surely had the knowledge, experience, and respect of the workers. He had been asking Jason Crofts for months for a chance at management, and he certainly wasn't about to let it get the better of him. His current problem had to do with scheduling. Since he had become supervisor the sales people always asked him about an order before they promised delivery to a customer. He thought that would be quite simple; after all, who knew more about the printing business than he did? Based on his knowledge of the processes and what was already in progress, he gave what he thought were reasonable, even conservative, estimates of promise dates. Unfortunately, his track record was not too good. There had been many late deliveries since his managerial appointment, and nobody in the organization was too happy about it. At first he thought it must be the other workers. "They're just jealous about my selection as supervisor and want to make me look bad" was his initial reaction. Henry Hurley, another long-time machine operator, was John's best friend. One afternoon over a beer, John asked Henry about the problem in a confidential discussion. Henry said he was sure that John had been trying to get it right but somehow it didn't seem to be going well. Henry assured John that the workers were trying their best. In fact, according to Henry, the workers had been putting in extra effort. They viewed John's promotion as a positive sign that there was a possible future for them in management as well. John's failure would have been, in fact, greatly discouraging to most of the workers. John then thought he might be the problem when it came to giving estimates. The sales people would almost always contact him about a possible job to ask him when it should be promised to the customer. His great knowledge of the printing business allowed him, be thought, to quickly come to a good estimate. Perhaps he was not as good at ectimating as he thought. To check this out, he looked at most of the jobs done during the last couple of weeks. In almost every case, the work recorded againt a job was almost exactly what he had estimated. What litile error existed was certainly not large enough to cause the problem. John trusted Henry and believed his account of the situation, and his analysis of the estimates convinced him the problem wasn't there. If it wasn't the workers and wasn't the estimates then what could it be? He must do something. Jason Crofts was a patient man, but there was a limit. He was worried about alienating his best customers, and at the same time knew he must be concerned ahout efficiency as a way to control cost. John decided there was a need to take drastic action to ease the situation, or at least to find out what the cause was. On a Friday he scheduled overtime for Saturday to finish all jobs in progress On Monday, therefore, he could start with a clean slate. There were sevcral jobs already promised, but not yet started. He figured that on Monday le could start with all new jobs and really figure out the source of his problem. The jobs were all promised within four days, but he figured there should be no problem. He had three operations, and most of the jobs went through all three, but not all jobs needed all operations. He had one worker assigned to each operation. Over the neat four days that represented 96 hours of available work time 3 coperations 4 days 8 hours John Burton was not a happy man. He was a supervisor for the Crofts Printing Company, hav ing been recently promoted from lead printer. While he felt very comfortable with his knowl edge and success in the printing business, this managerial position was starting to wear on him He was determined not to let it get him down, however, as he felt he surely had the knowledge, experience, and respect of the workers. He had been asking Jason Crofts for months for a chance at management, and he certainly wasn't about to let it get the better of him. His current problem had to do with scheduling. Since he had become supervisor the sales people always asked him about an order before they promised delivery to a customer. He thought that would be quite simple; after all, who knew more about the printing business than he did? Based on his knowledge of the processes and what was already in progress, he gave what he thought were reasonable, even conservative, estimates of promise dates. Unfortunately, his track record was not too good. There had been many late deliveries since his managerial appointment, and nobody in the organization was too happy about it. At first he thought it must be the other workers. "They're just jealous about my selection as supervisor and want to make me look bad" was his initial reaction. Henry Hurley. another long-time machine operator, was John's best friend. One afternoon over a beer, John asked Henry about the problem in a confidential discussion. Henry said he was sure that John had been trying to get it right but somehow it didn't seem to be going well. Henry assured John that the workers were trying their best. In fact, according to Henry. the workers had been putting in extra effort. They viewed John's promotion as a positive sign that there was a possible future for them in management as well. John's failure would have been, in fact, greatly discouraging to most of the workers. John then thought he might be the problem when it came to giving estimates. The sales people would almost always contact him about a posstble job to ask him when it should be promised to the customer. His great knowledge of the printing business allowed him, he thought, to quickly come to a good estimate. Perhaps he was not as good at estimating as he thought. To check this out, he looked at most of the jobs done during the last couple of weeks. In almost every case, the work recorded against a job was almost exactly what he had estimated. What little error existed was certainly not large enough to cause the problem. John trusted Henry and believed his account of the situation, and his analysis of the estimater convinced him the problem wasn't there. If it wasn't the workers and wasn't the estimates then what could it be? He must do something. Jason Crofts was a patient man. but there was a limit. He was worried about alienating his best customers, and at the same time knew he must be concerned about efficiency as a way to control cost. John decided there was a need to take drastic action to ease the situation, or at keast to John trusted Henry and believed his account of the situation, and his analysis of the estimates convinced him the problem wasn't there. If it wasn't the workers and wasn't the estimates then what could it be? He must do something. Jason Crofts was a patient man, but there was a limit. He was worried about alienating his best customers, and at the same time knew he must be concerned about efficiency as a way to control cost. John decided there was a need to take drastic action to ease the situation, or at least to find out what the cause was. On a Friday he scheduled overtime for Saturday to finish all jobs in progress. On Monday, therefore, he could start with a clean slate. There were several jobs already promised, but not yet started. He figured that on Monday he could start with all new jobs and really figure out the source of his problem. The jobs were all promised within four days, but he figured there should be no problem. He had three operations, and most of the jobs went through all three, but not all jobs needed all operations. He had one worker assigned to each operation. Over the next four days that represented 96 hours of available work time 3 operations 4 days 8 hours per day), he had eight jobs promised. The total estimated time for all eight jobs was only 88 hours, giving him a buffer of 8 hours over the next four days. To make sure there would be no problem, he decided there would be no new jobs even scheduled to start during those four days, with the only exception being if any operation completed all the necessary work for all eight jobs before the end of the four days, they could start another. In any case, he wanted to make sure that if necessary, all 96 hours would be reserved for just the 88 hours of scheduled work. John had learned that a good priority rule to use was the critical ratio rule, primarily because it took into account both the customer due date and the amount of processing time for a job. He therefore used that rule to prioritize the jobs. The following table shows the eight jobs, together with processing time estimates and due dates. All due dates are at the end of the day indicated. Processing times for all jobs at all three operations are in hours. Assignment 1. Using the critical ratio rule, establish the priority for the eight jobs. 2. Use a chart to load the operation according to the priority rule established. In other words, load the most important job in all three work centers, then the next most important, and so forth. This is the method that John used. 3. Analyze John's approach and try to determine if he has a problem, and if he does determine the source of the problem. 4. Try to provide a solution to John that will ease the problem. and perhaps eliminate it. per day), he had eight jobs promised. The total estimated time for all eight jobs was only 88 hours, giving him a buffer of 8 hours over the next four days. To make sure there would be no problem, he decided there would be no new jobs even scheduled to start during those four days, with the only exception being if any operation completed all the neces- hy-workifior all eight jobs before the end of the four days, they could start anditice. In any Cas. hours of whechedulod work. Jokin had leamed that a good priority rule to use was the critical ratio rule primarily because in took into account both the customer due date and the amount of prockssing timest for a job. Ho therefore used that rule to prioritize the jobs. The followin cight jobs, together with processing time estimates and due dates. All due dates are at the cod of the diny indicaied. Processing times for all jobs at all three operations are in haulin Assignment 1. Using the critical ratio rule, establish the priority for the eight jobs. 2. Use a chart to load the operation according to the priority rule established. In other words, load the most important job in all three work centers, then the next most important, and so forth. This is the method that John used. 3. Analyze John's approach and try to determine if he has a problem, and if he does determine the source of the problem. 4. Try to provide a solution to John that will case the problem, and perhaps eliminate it. Ig been recently promoted from lead printer. While he felt very comfortable with his knowedge and success in the printing business, this managerial position was starting to wear on him. He was determined not to let it get him down, however, as he felt he surely had the knowledge, experience, and respect of the workers. He had been asking Jason Crofts for months for a chance at management, and he certainly wasn't about to let it get the better of him. His current problem had to do with scheduling. Since he had become supervisor the sales people always asked him about an order before they promised delivery to a customer. He thought that would be quite simple; after all, who knew more about the printing business than he did? Based on his knowledge of the processes and what was already in progress, he gave what he thought were reasonable, even conservative, estimates of promise dates. Unfortunately, his track record was not too good. There had been many late deliveries since his managerial appointment, and nobody in the organization was too happy about it. At first he thought it must be the other workers. "They're just jealous about my selection as supervisor and want to make me look bad" was his initial reaction. Henry Hurley, another long-time machine operator, was John's best friend. One afternoon over a beer, John asked Henry about the problem in a confidential discussion. Henry said he was sure that John had been trying to get it right but somehow it didn't seem to be going well. Henry assured John that the workers were trying their best. In fact, according to Henry, the workers had been putting in extra effort. They viewed John's promotion as a positive sign that there was a possible future for them in management as well. John's failure would have been, in fact, greatly discouraging to most of the workers. John then thought he might be the problem when it came to giving estimates. The sales people would almost always contact him about a possible job to ask him when it should be promised to the customer. His great knowledge of the printing business allowed him, be thought, to quickly come to a good estimate. Perhaps he was not as good at ectimating as he thought. To check this out, he looked at most of the jobs done during the last couple of weeks. In almost every case, the work recorded againt a job was almost exactly what he had estimated. What litile error existed was certainly not large enough to cause the problem. John trusted Henry and believed his account of the situation, and his analysis of the estimates convinced him the problem wasn't there. If it wasn't the workers and wasn't the estimates then what could it be? He must do something. Jason Crofts was a patient man, but there was a limit. He was worried about alienating his best customers, and at the same time knew he must be concerned ahout efficiency as a way to control cost. John decided there was a need to take drastic action to ease the situation, or at least to find out what the cause was. On a Friday he scheduled overtime for Saturday to finish all jobs in progress On Monday, therefore, he could start with a clean slate. There were sevcral jobs already promised, but not yet started. He figured that on Monday le could start with all new jobs and really figure out the source of his problem. The jobs were all promised within four days, but he figured there should be no problem. He had three operations, and most of the jobs went through all three, but not all jobs needed all operations. He had one worker assigned to each operation. Over the neat four days that represented 96 hours of available work time 3 coperations 4 days 8 hours John Burton was not a happy man. He was a supervisor for the Crofts Printing Company, hav ing been recently promoted from lead printer. While he felt very comfortable with his knowl edge and success in the printing business, this managerial position was starting to wear on him He was determined not to let it get him down, however, as he felt he surely had the knowledge, experience, and respect of the workers. He had been asking Jason Crofts for months for a chance at management, and he certainly wasn't about to let it get the better of him. His current problem had to do with scheduling. Since he had become supervisor the sales people always asked him about an order before they promised delivery to a customer. He thought that would be quite simple; after all, who knew more about the printing business than he did? Based on his knowledge of the processes and what was already in progress, he gave what he thought were reasonable, even conservative, estimates of promise dates. Unfortunately, his track record was not too good. There had been many late deliveries since his managerial appointment, and nobody in the organization was too happy about it. At first he thought it must be the other workers. "They're just jealous about my selection as supervisor and want to make me look bad" was his initial reaction. Henry Hurley. another long-time machine operator, was John's best friend. One afternoon over a beer, John asked Henry about the problem in a confidential discussion. Henry said he was sure that John had been trying to get it right but somehow it didn't seem to be going well. Henry assured John that the workers were trying their best. In fact, according to Henry. the workers had been putting in extra effort. They viewed John's promotion as a positive sign that there was a possible future for them in management as well. John's failure would have been, in fact, greatly discouraging to most of the workers. John then thought he might be the problem when it came to giving estimates. The sales people would almost always contact him about a posstble job to ask him when it should be promised to the customer. His great knowledge of the printing business allowed him, he thought, to quickly come to a good estimate. Perhaps he was not as good at estimating as he thought. To check this out, he looked at most of the jobs done during the last couple of weeks. In almost every case, the work recorded against a job was almost exactly what he had estimated. What little error existed was certainly not large enough to cause the problem. John trusted Henry and believed his account of the situation, and his analysis of the estimater convinced him the problem wasn't there. If it wasn't the workers and wasn't the estimates then what could it be? He must do something. Jason Crofts was a patient man. but there was a limit. He was worried about alienating his best customers, and at the same time knew he must be concerned about efficiency as a way to control cost. John decided there was a need to take drastic action to ease the situation, or at keast to John trusted Henry and believed his account of the situation, and his analysis of the estimates convinced him the problem wasn't there. If it wasn't the workers and wasn't the estimates then what could it be? He must do something. Jason Crofts was a patient man, but there was a limit. He was worried about alienating his best customers, and at the same time knew he must be concerned about efficiency as a way to control cost. John decided there was a need to take drastic action to ease the situation, or at least to find out what the cause was. On a Friday he scheduled overtime for Saturday to finish all jobs in progress. On Monday, therefore, he could start with a clean slate. There were several jobs already promised, but not yet started. He figured that on Monday he could start with all new jobs and really figure out the source of his problem. The jobs were all promised within four days, but he figured there should be no problem. He had three operations, and most of the jobs went through all three, but not all jobs needed all operations. He had one worker assigned to each operation. Over the next four days that represented 96 hours of available work time 3 operations 4 days 8 hours per day), he had eight jobs promised. The total estimated time for all eight jobs was only 88 hours, giving him a buffer of 8 hours over the next four days. To make sure there would be no problem, he decided there would be no new jobs even scheduled to start during those four days, with the only exception being if any operation completed all the necessary work for all eight jobs before the end of the four days, they could start another. In any case, he wanted to make sure that if necessary, all 96 hours would be reserved for just the 88 hours of scheduled work. John had learned that a good priority rule to use was the critical ratio rule, primarily because it took into account both the customer due date and the amount of processing time for a job. He therefore used that rule to prioritize the jobs. The following table shows the eight jobs, together with processing time estimates and due dates. All due dates are at the end of the day indicated. Processing times for all jobs at all three operations are in hours. Assignment 1. Using the critical ratio rule, establish the priority for the eight jobs. 2. Use a chart to load the operation according to the priority rule established. In other words, load the most important job in all three work centers, then the next most important, and so forth. This is the method that John used. 3. Analyze John's approach and try to determine if he has a problem, and if he does determine the source of the problem. 4. Try to provide a solution to John that will ease the problem. and perhaps eliminate it

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts