Question: I think I understand how to do this Assignment, although, I am needed help with calculating items produced in Excel in order to finish my

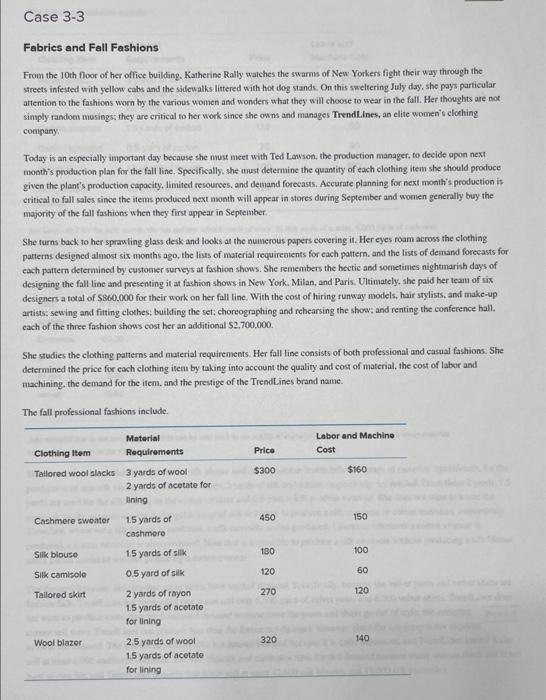

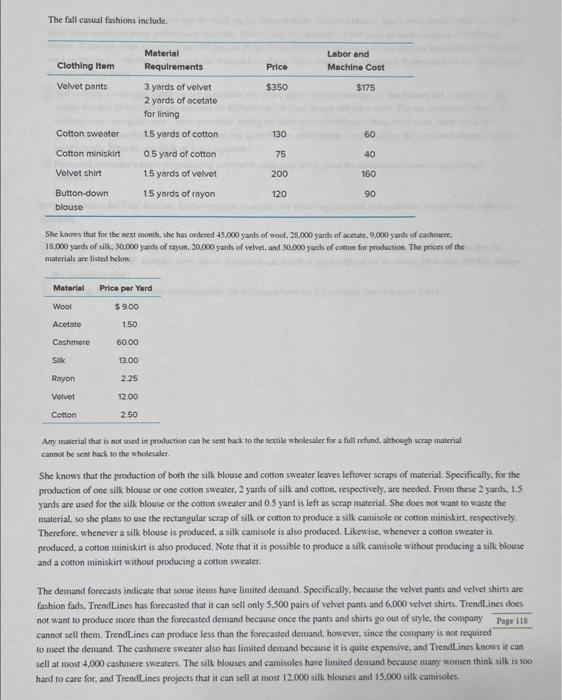

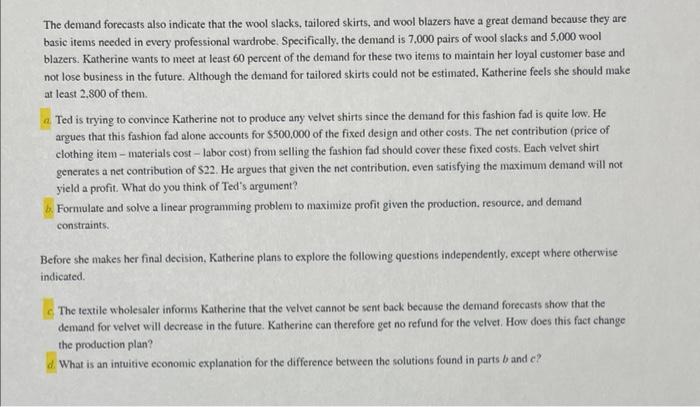

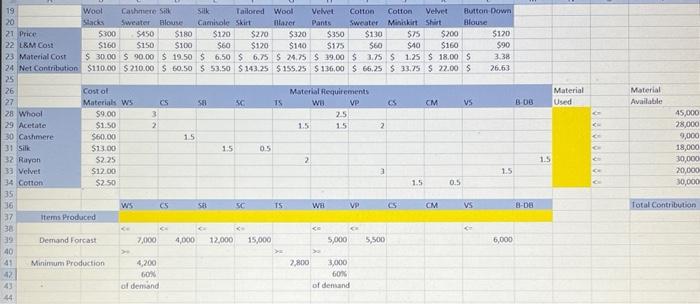

Fabrics and Fall Fashions From the 10 th floor of her office building. Katherine Rally watches the swarm of New Yorkers fight their way through the sreets infested with yellow cahs and the sidewalks littered with hot dog stands. On this sweltering July day, she pays particular attention to the fashions wom by the various women and wonders what they will choose to wear in the fall. Her thoughts are not simply randoen musings: they are critical to her work since she owns and manages TrendL.ines, an elite women's cloching. company: Today is an especially important day because she must meet with Ted Lowson, the production manager, to decide opon next month's production plan for the fall line. Specifically. she must determine the quantity of each clothing item she should prodoce given the plant's production capacity, limited resources, and demand forecasts. Accurate planning for next month's production is critical to fall sales since the items produced next month will appear in stores during September and woalen generally buy the majority of the fall fashions whes they first appear in September. She turns back to her sprawling glass desk and looks af the numerous papers covering it. Her eyes roam across the clothing pattems designed alnost six months ago, the lists of material requirements for each pattern, and the lists of demand foreeasts for each pattern deternined by customer surveys at fashion shows. She remembers the hectic and socnetimes nightmarish days of designing the fall line and presenting it at fashion shows in New York. Milan, and Paris. Ultimately, she paid her team of six designers a total of $860,000 for their work on her fall tine. With the cost of hiring runway models, hair sylists, and make-up artists: sewing and fitting clothes; building the set. choreographing and rehearsing the show: and renting the conference hall. each of the three fashioa shows cost her an additional $2,700,000. She studies the clothing patrerns and material requireaents. Her fall line consists of both professional and casual fashions. She determined the price for each clothing iten by taking into account the qualiry and cost of material, the cost of labor and machining, the demand for the ifem, and the prestige of the TrendLines brand name. The fall professional fashions include. The fall casual fashions include: She knows that for the eext month, she has ondered 45.000 yants of wook, 28.000 yants of acctate, 9.000 yarbl of eathmere, 18,000 yands of silk, 30,000 yants of rayon. 30,000 yants of velvet, and 30,000 yands of conion for prodaction. The prices of the materials are listed below. Any material that is not used in production ean be sent back to the textile wholesaler for a full refund, although scrap material cannot be sear back to the wholeialer. She knows that the production of boch the silk blouse and cotton sweater leaves leftover scraps of material. Specifically, for the prodoction of one silk blouse or one cotion sweater. 2 yards of silk and cotton, respectively, are needed. From these Z yarks, 1.5 yards are used for the silk blouse or the cotton sweater and 0.5 yand is left as serap material, She does not want to waste the material, so she plans to use the rectangular serap of silk or cotton to produce a silk camisole or cotton miniskirt, respectively. Therefore, whenever a silk blouse is produced, a silk camisole is also produced. Likew ise, whenever a cotton sweater is produced, a cotton miniskirt is also produced, Note that it is possible to produce a silk camisole withour producing a silk blouse and a cotton miniskirt without producing a cotton sweater: The demand forecasts indicate that some itens have limited demand. Specifically, because the velvet pants and velvet shirts are fashion fads. TrendLines has forecasted that it can sell only 5.500 pairs of velvet pants and 6.000 velvet shirts. TrendLines does not want to produce asore than the forecasted demand because once the pants and shirts go out of uryle, the company cannot sell them. TrendLines can produce less than the forecasted denand, however, since the company is not required to meet the demand. The cashmere sweater also has limited denand because it is quite expensive, and TrendLines knows it can sell at niost 4,000 cashmere sweaters. The silk blouses and camisoles have limited denund because many wonen think silk is too hard to care for, and TrendLines projects that it can sell at most 12.000 silk blouses and 15.000 silk camisoles. The demand forecasts also indicate that the wool slacks, tailored skirts, and wool blazers have a great demand because they are basic items needed in every professional wardrobe. Specifically, the demand is 7.000 pairs of wool slacks and 5.000 wool blazers. Katherine wants to meet at least 60 percent of the demand for these two items to maintain her loyal customer base and not lose business in the future. Although the demand for tailored skirts could not be estimated, Katherine feels she should make at least 2.800 of them. Ted is trying to convince Katherine not to produce any velvet shirts since the denand for this fashion fad is quite low. He argues that this fashion fad alone accounts for $500,000 of the fixed design and other costs. The net contribution (price of clothing item - materials cost - labor cost) from selling the fashion fad should cover these fixed costs. Each velvet shirt generates a net contribution of $22. He argues that given the net contribution. even satisfying the maximum demand will not yield a profit. What do you think of Ted's argument? Formulate and solve a linear programming problem to maximize profit given the production, resource, and demand constraints. Before she makes her final decision. Katherine plans to explore the following questions independently, except where otherwise indicated. The textile wholesaler informs Katherine that the velvet cannot be sent back because the demand forecasts show that the demand for velvet will decrease in the future. Katherine can therefore get no refund for the velvet. How does this fact change the production plan? What is an intuitive economic explanation for the difference between the solutions found in parts b and c ? Fabrics and Fall Fashions From the 10 th floor of her office building. Katherine Rally watches the swarm of New Yorkers fight their way through the sreets infested with yellow cahs and the sidewalks littered with hot dog stands. On this sweltering July day, she pays particular attention to the fashions wom by the various women and wonders what they will choose to wear in the fall. Her thoughts are not simply randoen musings: they are critical to her work since she owns and manages TrendL.ines, an elite women's cloching. company: Today is an especially important day because she must meet with Ted Lowson, the production manager, to decide opon next month's production plan for the fall line. Specifically. she must determine the quantity of each clothing item she should prodoce given the plant's production capacity, limited resources, and demand forecasts. Accurate planning for next month's production is critical to fall sales since the items produced next month will appear in stores during September and woalen generally buy the majority of the fall fashions whes they first appear in September. She turns back to her sprawling glass desk and looks af the numerous papers covering it. Her eyes roam across the clothing pattems designed alnost six months ago, the lists of material requirements for each pattern, and the lists of demand foreeasts for each pattern deternined by customer surveys at fashion shows. She remembers the hectic and socnetimes nightmarish days of designing the fall line and presenting it at fashion shows in New York. Milan, and Paris. Ultimately, she paid her team of six designers a total of $860,000 for their work on her fall tine. With the cost of hiring runway models, hair sylists, and make-up artists: sewing and fitting clothes; building the set. choreographing and rehearsing the show: and renting the conference hall. each of the three fashioa shows cost her an additional $2,700,000. She studies the clothing patrerns and material requireaents. Her fall line consists of both professional and casual fashions. She determined the price for each clothing iten by taking into account the qualiry and cost of material, the cost of labor and machining, the demand for the ifem, and the prestige of the TrendLines brand name. The fall professional fashions include. The fall casual fashions include: She knows that for the eext month, she has ondered 45.000 yants of wook, 28.000 yants of acctate, 9.000 yarbl of eathmere, 18,000 yands of silk, 30,000 yants of rayon. 30,000 yants of velvet, and 30,000 yands of conion for prodaction. The prices of the materials are listed below. Any material that is not used in production ean be sent back to the textile wholesaler for a full refund, although scrap material cannot be sear back to the wholeialer. She knows that the production of boch the silk blouse and cotton sweater leaves leftover scraps of material. Specifically, for the prodoction of one silk blouse or one cotion sweater. 2 yards of silk and cotton, respectively, are needed. From these Z yarks, 1.5 yards are used for the silk blouse or the cotton sweater and 0.5 yand is left as serap material, She does not want to waste the material, so she plans to use the rectangular serap of silk or cotton to produce a silk camisole or cotton miniskirt, respectively. Therefore, whenever a silk blouse is produced, a silk camisole is also produced. Likew ise, whenever a cotton sweater is produced, a cotton miniskirt is also produced, Note that it is possible to produce a silk camisole withour producing a silk blouse and a cotton miniskirt without producing a cotton sweater: The demand forecasts indicate that some itens have limited demand. Specifically, because the velvet pants and velvet shirts are fashion fads. TrendLines has forecasted that it can sell only 5.500 pairs of velvet pants and 6.000 velvet shirts. TrendLines does not want to produce asore than the forecasted demand because once the pants and shirts go out of uryle, the company cannot sell them. TrendLines can produce less than the forecasted denand, however, since the company is not required to meet the demand. The cashmere sweater also has limited denand because it is quite expensive, and TrendLines knows it can sell at niost 4,000 cashmere sweaters. The silk blouses and camisoles have limited denund because many wonen think silk is too hard to care for, and TrendLines projects that it can sell at most 12.000 silk blouses and 15.000 silk camisoles. The demand forecasts also indicate that the wool slacks, tailored skirts, and wool blazers have a great demand because they are basic items needed in every professional wardrobe. Specifically, the demand is 7.000 pairs of wool slacks and 5.000 wool blazers. Katherine wants to meet at least 60 percent of the demand for these two items to maintain her loyal customer base and not lose business in the future. Although the demand for tailored skirts could not be estimated, Katherine feels she should make at least 2.800 of them. Ted is trying to convince Katherine not to produce any velvet shirts since the denand for this fashion fad is quite low. He argues that this fashion fad alone accounts for $500,000 of the fixed design and other costs. The net contribution (price of clothing item - materials cost - labor cost) from selling the fashion fad should cover these fixed costs. Each velvet shirt generates a net contribution of $22. He argues that given the net contribution. even satisfying the maximum demand will not yield a profit. What do you think of Ted's argument? Formulate and solve a linear programming problem to maximize profit given the production, resource, and demand constraints. Before she makes her final decision. Katherine plans to explore the following questions independently, except where otherwise indicated. The textile wholesaler informs Katherine that the velvet cannot be sent back because the demand forecasts show that the demand for velvet will decrease in the future. Katherine can therefore get no refund for the velvet. How does this fact change the production plan? What is an intuitive economic explanation for the difference between the solutions found in parts b and c

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts