Question: Identify a systematic or position/circumstance solution that could be deployed for an employee relations matter outlined in the caselette. To receive full credit you must:

Identify a systematic or position/circumstance solution that could be deployed for an employee relations matter outlined in the caselette. To receive full credit you must:

- List a solution for an employee relations matter outlined in the caselette

- Correctly identify whether your solution is a systematic solution or a position/circumstance solution in your response

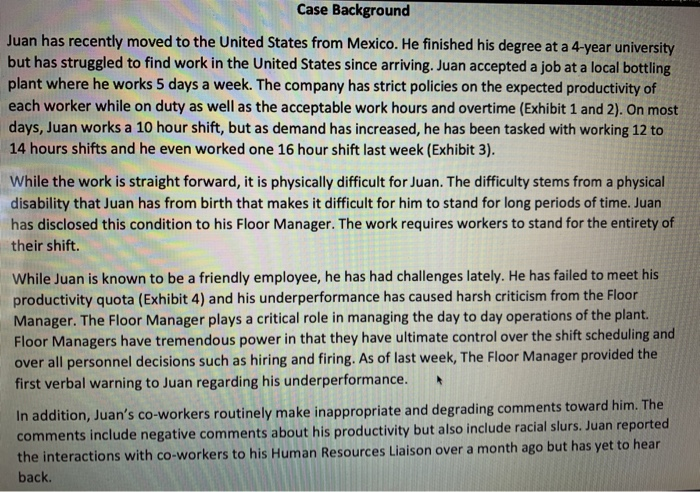

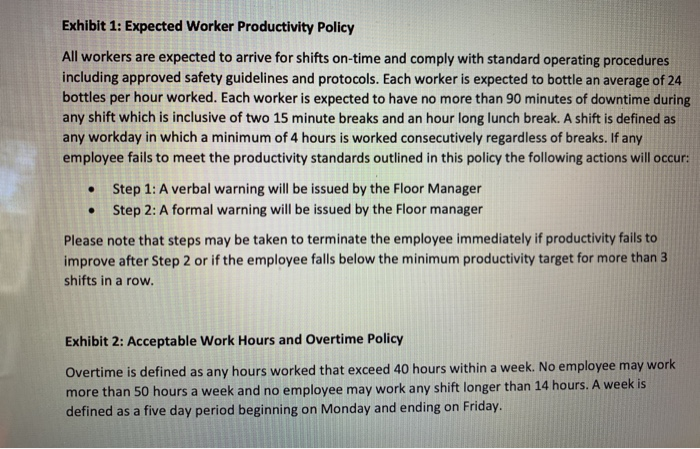

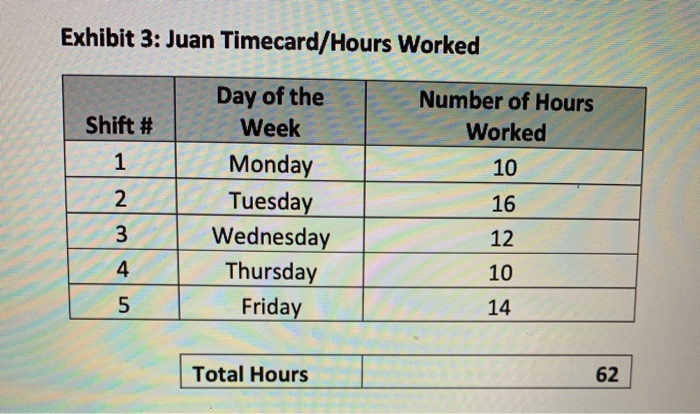

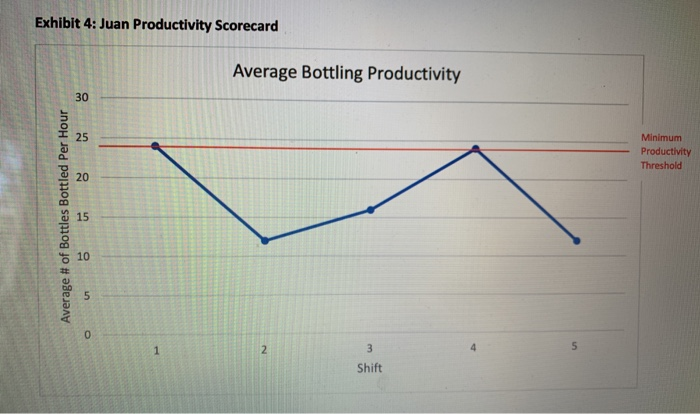

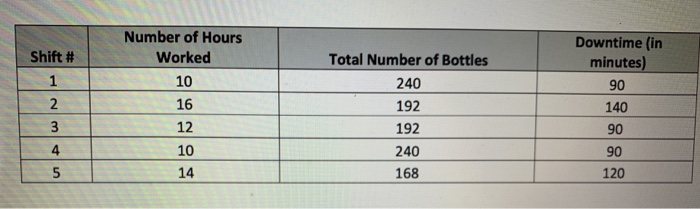

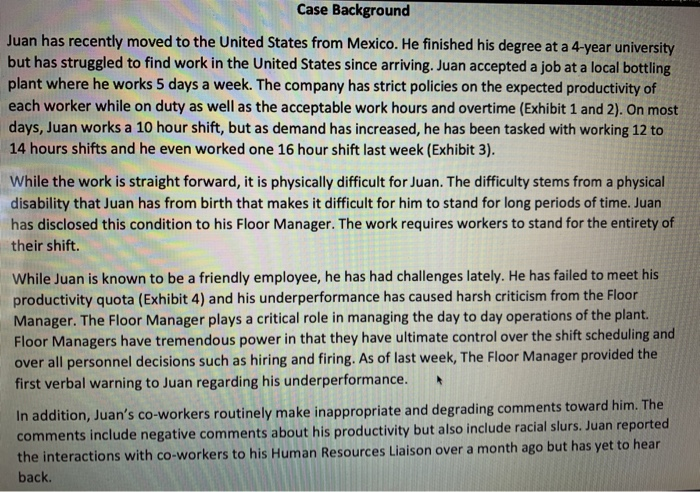

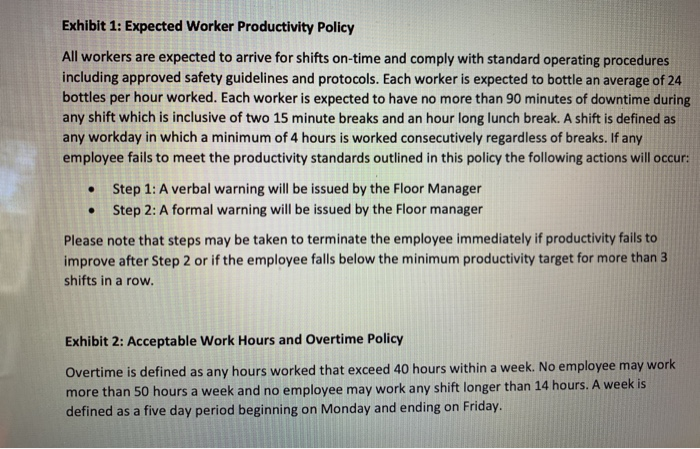

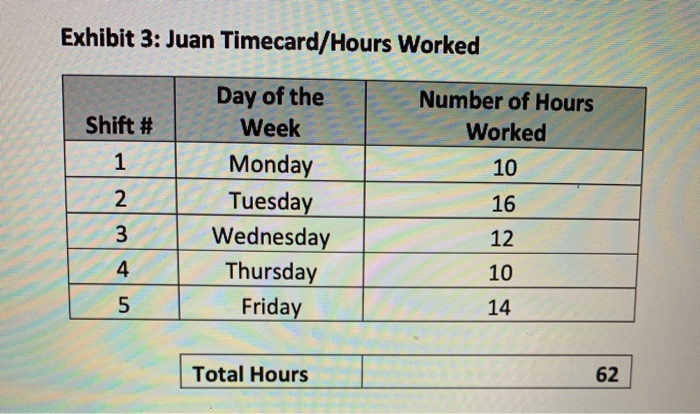

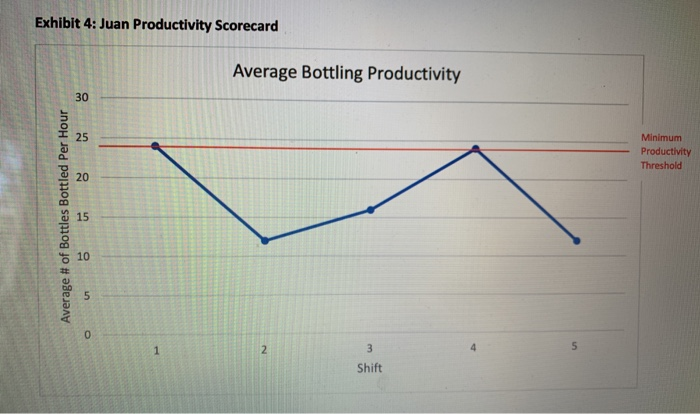

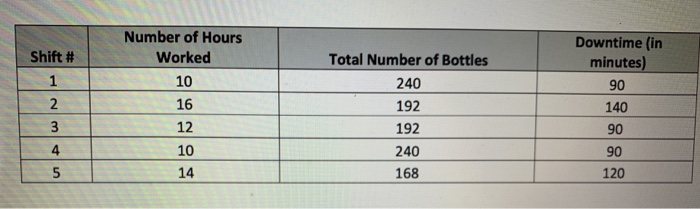

Case Background Juan has recently moved to the United States from Mexico. He finished his degree at a 4-year university but has struggled to find work in the United States since arriving. Juan accepted a job at a local bottling plant where he works 5 days a week. The company has strict policies on the expected productivity of each worker while on duty as well as the acceptable work hours and overtime (Exhibit 1 and 2). On most days, Juan works a 10 hour shift, but as demand has increased, he has been tasked with working 12 to 14 hours shifts and he even worked one 16 hour shift last week (Exhibit 3). While the work is straight forward, it is physically difficult for Juan. The difficulty stems from a physical disability that Juan has from birth that makes it difficult for him to stand for long periods of time. Juan has disclosed this condition to his Floor Manager. The work requires workers to stand for the entirety of their shift. While Juan is known to be a friendly employee, he has had challenges lately. He has failed to meet his productivity quota (Exhibit 4) and his underperformance has caused harsh criticism from the Floor Manager. The Floor Manager plays a critical role in managing the day to day operations of the plant. Floor Managers have tremendous power in that they have ultimate control over the shift scheduling and over all personnel decisions such as hiring and firing. As of last week, The Floor Manager provided the first verbal warning to Juan regarding his underperformance. In addition, Juan's co-workers routinely make inappropriate and degrading comments toward him. The comments include negative comments about his productivity but also include racial slurs, Juan reported the interactions with co-workers to his Human Resources Liaison over a month ago but has yet to hear back Exhibit 1: Expected Worker Productivity Policy All workers are expected to arrive for shifts on-time and comply with standard operating procedures including approved safety guidelines and protocols. Each worker is expected to bottle an average of 24 bottles per hour worked. Each worker is expected to have no more than 90 minutes of downtime during any shift which is inclusive of two 15 minute breaks and an hour long lunch break. A shift is defined as any workday in which a minimum of 4 hours is worked consecutively regardless of breaks. If any employee fails to meet the productivity standards outlined in this policy the following actions will occur: Step 1: A verbal warning will be issued by the Floor Manager Step 2: A formal warning will be issued by the Floor manager Please note that steps may be taken to terminate the employee immediately if productivity fails to improve after Step 2 or if the employee falls below the minimum productivity target for more than 3 shifts in a row. . Exhibit 2: Acceptable Work Hours and Overtime Policy Overtime is defined as any hours worked that exceed 40 hours within a week. No employee may work more than 50 hours a week and no employee may work any shift longer than 14 hours. A week is defined as a five day period beginning on Monday and ending on Friday. Exhibit 3: Juan Timecard/Hours Worked Shift # Number of Hours Worked 1 10 2 Day of the Week Monday Tuesday Wednesday Thursday Friday 16 3 12 4 10 5 14 Total Hours 62 Exhibit 4: Juan Productivity Scorecard Average Bottling Productivity 30 25 Minimum Productivity Threshold 20 Average # of Bottles Bottled Per Hour 15 10 5 0 1 2 3 5 Shift Shift # 1 2 3 Number of Hours Worked 10 16 12 10 14 Total Number of Bottles 240 192 192 240 168 Downtime (in minutes) 90 140 90 90 120 3 4 5 Case Background Juan has recently moved to the United States from Mexico. He finished his degree at a 4-year university but has struggled to find work in the United States since arriving. Juan accepted a job at a local bottling plant where he works 5 days a week. The company has strict policies on the expected productivity of each worker while on duty as well as the acceptable work hours and overtime (Exhibit 1 and 2). On most days, Juan works a 10 hour shift, but as demand has increased, he has been tasked with working 12 to 14 hours shifts and he even worked one 16 hour shift last week (Exhibit 3). While the work is straight forward, it is physically difficult for Juan. The difficulty stems from a physical disability that Juan has from birth that makes it difficult for him to stand for long periods of time. Juan has disclosed this condition to his Floor Manager. The work requires workers to stand for the entirety of their shift. While Juan is known to be a friendly employee, he has had challenges lately. He has failed to meet his productivity quota (Exhibit 4) and his underperformance has caused harsh criticism from the Floor Manager. The Floor Manager plays a critical role in managing the day to day operations of the plant. Floor Managers have tremendous power in that they have ultimate control over the shift scheduling and over all personnel decisions such as hiring and firing. As of last week, The Floor Manager provided the first verbal warning to Juan regarding his underperformance. In addition, Juan's co-workers routinely make inappropriate and degrading comments toward him. The comments include negative comments about his productivity but also include racial slurs, Juan reported the interactions with co-workers to his Human Resources Liaison over a month ago but has yet to hear back Exhibit 1: Expected Worker Productivity Policy All workers are expected to arrive for shifts on-time and comply with standard operating procedures including approved safety guidelines and protocols. Each worker is expected to bottle an average of 24 bottles per hour worked. Each worker is expected to have no more than 90 minutes of downtime during any shift which is inclusive of two 15 minute breaks and an hour long lunch break. A shift is defined as any workday in which a minimum of 4 hours is worked consecutively regardless of breaks. If any employee fails to meet the productivity standards outlined in this policy the following actions will occur: Step 1: A verbal warning will be issued by the Floor Manager Step 2: A formal warning will be issued by the Floor manager Please note that steps may be taken to terminate the employee immediately if productivity fails to improve after Step 2 or if the employee falls below the minimum productivity target for more than 3 shifts in a row. . Exhibit 2: Acceptable Work Hours and Overtime Policy Overtime is defined as any hours worked that exceed 40 hours within a week. No employee may work more than 50 hours a week and no employee may work any shift longer than 14 hours. A week is defined as a five day period beginning on Monday and ending on Friday. Exhibit 3: Juan Timecard/Hours Worked Shift # Number of Hours Worked 1 10 2 Day of the Week Monday Tuesday Wednesday Thursday Friday 16 3 12 4 10 5 14 Total Hours 62 Exhibit 4: Juan Productivity Scorecard Average Bottling Productivity 30 25 Minimum Productivity Threshold 20 Average # of Bottles Bottled Per Hour 15 10 5 0 1 2 3 5 Shift Shift # 1 2 3 Number of Hours Worked 10 16 12 10 14 Total Number of Bottles 240 192 192 240 168 Downtime (in minutes) 90 140 90 90 120 3 4 5