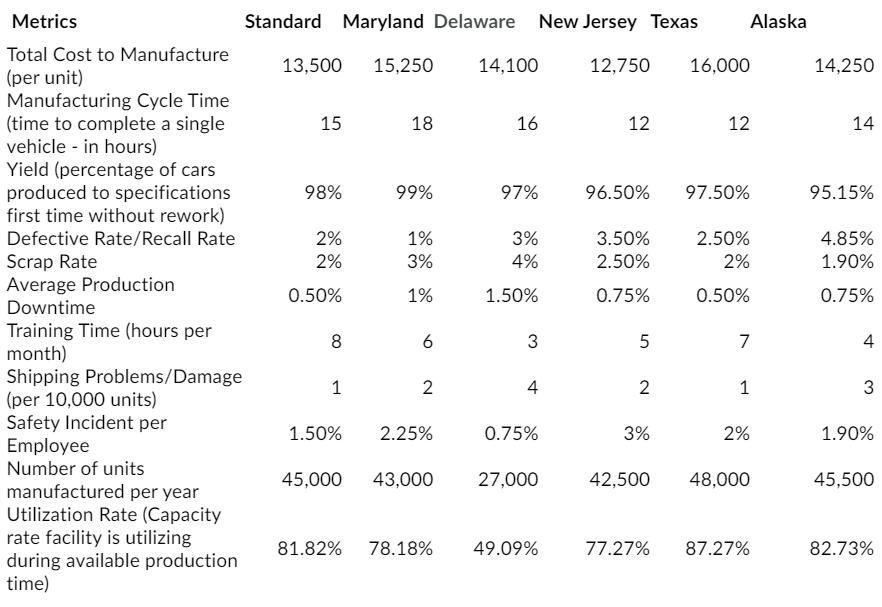

Question: Identify the four (4) most important and common deviations from the standards among the plants and explain why this data is important to Lacks Tracks

- Identify the four (4) most important and common deviations from the standards among the plants and explain why this data is important to Lacks Tracks management

Metrics Total Cost to Manufacture (per unit] Manufacturing Cycle Time (time to complete a single vehicle - in hours] Yield (percentage of cars produced to specifications first time without rework) Defective Rate! Recall Rate Scrap Rate Average Production Downtime Training Time (hours per month) Shipping Problemstamage (per 10,000 units) Safety Incident per Employee Number of units manufactured per year Utilization Rate {Capacity rate facility is utilizing during available production time] Standard Maryland Delaware 13,500 15 98% 2% 2% 0.50% 1.50% 45,000 81.82% 15,250 18 99% 1% 3% 1% 2.25% 43,000 28.18% 14, 100 16 92% 3% 4% 1.50% 0.25% 22,000 49.09% New Jersey Texas Alaska 12,250 16,000 12 12 96.50% 92.50% 3.50% 2.50% 2.50% 2% 0.25% 0.50% 5 2 2 1 3% 2% 42,500 48,000 22.22% 82.22% 14.250 14 95.15% 4.85% 1.90% 0.25% 1.90% 45,500 82.23%

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts