Question: Il touch 6:08 PM @ 1 57% docs.google.com McDonald's Supply Chain Management and Logistics In 1996, when McDonald's entered India, it was looking for a

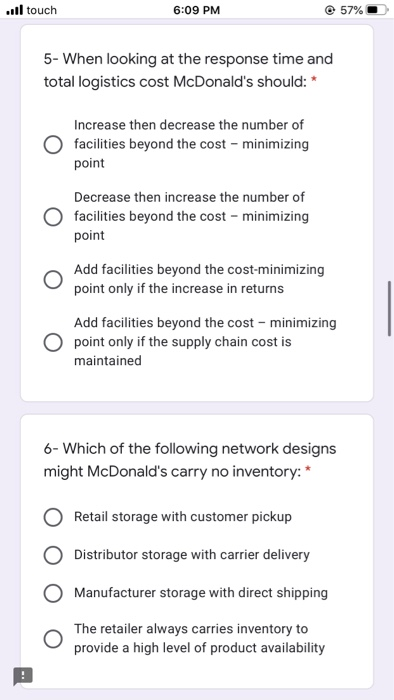

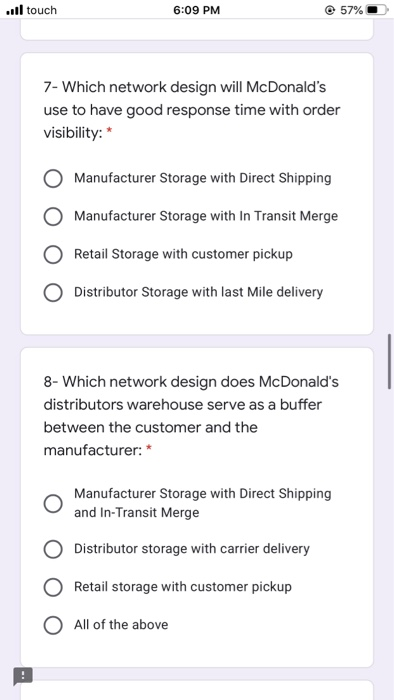

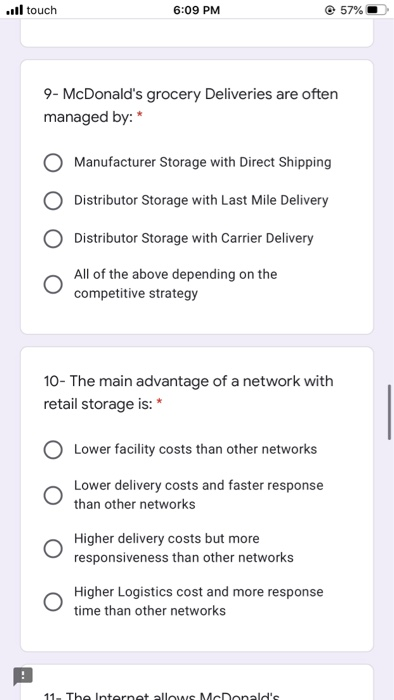

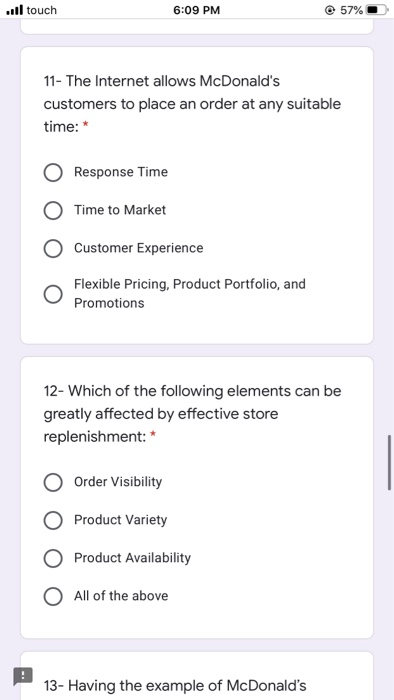

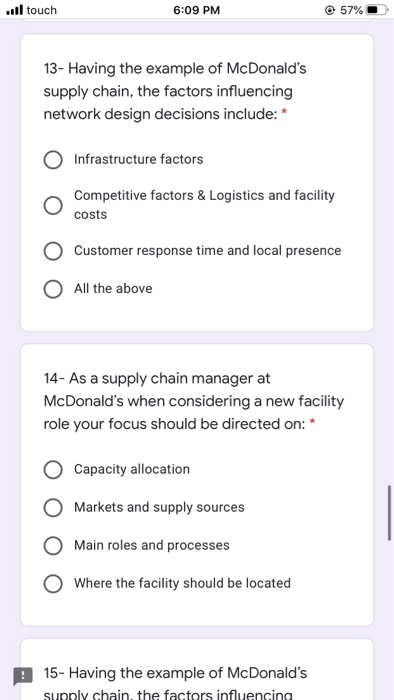

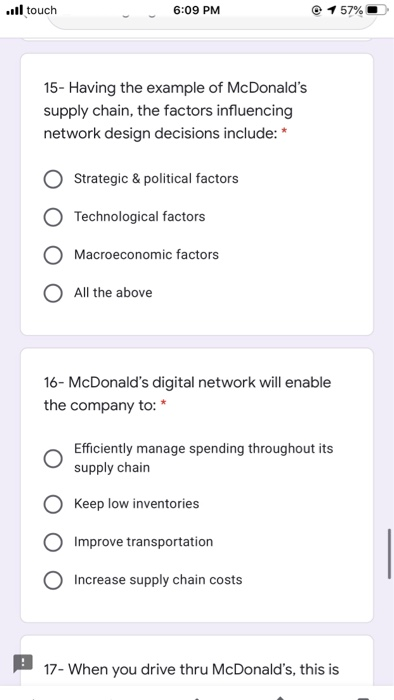

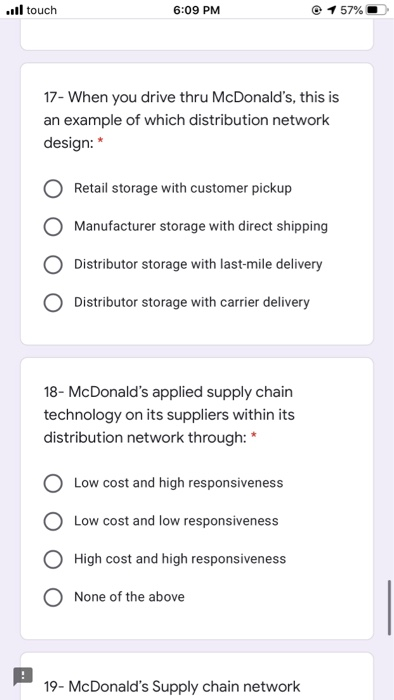

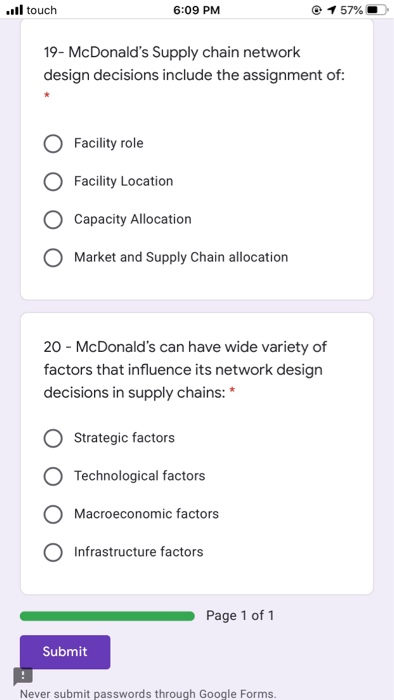

Il touch 6:08 PM @ 1 57% docs.google.com McDonald's Supply Chain Management and Logistics In 1996, when McDonald's entered India, it was looking for a distribution agent who would act as a hub for all its vendors. Radhakrishna Foodland Private Limited (RFPL) stored the products in controlled conditions in Mumbai and New Delhi and supplied them to McDonald's outlets on a daily basis. By transporting the semi-finished products at a particular temperature, the cold chain ensured freshness and adequate moisture content of the food. The specially designed trucks maintained the temperature in the storage chamber throughout the journey. Drivers were instructed specifically not to switch off the chilling system to save electricity, even in the event of traffic jam. We have to ensure that the integrity of the product is maintained throughout the cold chain. REPL also handled McDonald's inventory management. It had to anticipate future requirements and contingencies and plan for optimum utilization of the refrigerated vehicles. The challenge was the physical movement of material and inventory control in a country with bad roads and basic infrastructure bottlenecks. At the same time, unused capacity in the vehicles was used to transport goods from other vendors. This helped Coughlin deliver the lowest cost with the highest quality. To begin with, while the restaurants were not supposed to stock more than three days of inventory, the time limit for distribution centers or warehouses was a stringent 14 days to minimize costs and optimize quality control. This required round-the-clock monitoring of pick-ups and truck movements. Since most of the items were perishable, McDonald's standards covered the entire delivery schedules. For in-city delivery, the truck was monitored ..ll touch 6:08 PM @ 1 57% basic infrastructure bottlenecks. At the same time, unused capacity in the vehicles was used to transport goods from other vendors. This helped Coughlin deliver the lowest cost with the highest quality. To begin with, while the restaurants were not supposed to stock more than three days of inventory, the time limit for distribution centers or warehouses was a stringent 14 days to minimize costs and optimize quality control. This required round-the-clock monitoring of pick-ups and truck movements. Since most of the items were perishable, McDonald's standards covered the entire delivery schedules. For in-city delivery, the truck was monitored from the time it left the distribution center till the time it reached the restaurant. The products were transported from the suppliers' end to the distribution center in refrigerated and insulated vehicles through a system of consolidation to ensure better utilization of vehicle capacity McDonald's insisted on standardization by its suppliers which supplied the pies, nuggets, vegetable, and chicken patties, commissioned a new facility for the purpose in 1996, complete with insulated panels, temperature control, and chill rooms. McDonald's also assisted its suppliers with improvements. McDonald's was able to bring technology to its suppliers too. McDonald's had also applied supply chain technology when setting up Dynamix Dairy Industries Limited McDonald's convinced its suppliers to set up two separate production lines for chicken and vegetable patties, keeping in the mind the link between food and religion in India. This was in sharp contrast with its global practice, where McDonald's suppliers produced all types of patties from the same line. However, from a supplier's point of view, more lines meant a reduction in capacity utilization and high cost of production. To minimize costs, McDonald's helped Vista & Kitran Foods produce derivatives of chicken and vegetable nuggets (not based on McDonald's recipe) for Indian hotels and restaurants and thereby reach new markets. Vista & Kitran's higher margin and higher capacity utilization for non- McDonald's products helped it remain cost competitive. = ..ll touch 6:08 PM 57% 1- McDonald's distribution network which aims to serve customers who value short response times need to: * Decrease the number of facilities Increases the number of facilities Decrease inventory cost It depends on other attributes 2- One dimension that helps evaluating McDonald's distribution network performance is: Response Time Value provided to the customer Number of facilities All of the above 3- McDonald's Customer value aspects affected by the distribution network design alda Il touch 6:08 PM @ 57% 3- McDonald's Customer value aspects affected by the distribution network design include: * Customer perception Customer priorities Customer experience All of the above 4- As long as McDonald's inbound transportation economies of scale is maintained, increasing the number of facilities: * Increases total transportation cost Decreases total transportation cost Decreases transportation cost to a certain level and then increases it It depends on the desired responsiveness that the distribution network seeks to meet 5- When looking at the response time and Il touch 6:09 PM 57% 5- When looking at the response time and total logistics cost McDonald's should: * Increase then decrease the number of facilities beyond the cost - minimizing point Decrease then increase the number of facilities beyond the cost - minimizing point Add facilities beyond the cost-minimizing point only if the increase in returns Add facilities beyond the cost - minimizing point only if the supply chain cost is maintained 6- Which of the following network designs might McDonald's carry no inventory: * Retail storage with customer pickup Distributor storage with carrier delivery Manufacturer storage with direct shipping The retailer always carries inventory to provide a high level of product availability ...l touch 6:09 PM @ 57% 7- Which network design will McDonald's use to have good response time with order visibility: * Manufacturer Storage with Direct Shipping Manufacturer Storage with In Transit Merge Retail Storage with customer pickup Distributor Storage with last Mile delivery 8- Which network design does McDonald's distributors warehouse serve as a buffer between the customer and the manufacturer: * Manufacturer Storage with Direct Shipping and In-Transit Merge Distributor storage with carrier delivery Retail storage with customer pickup O All of the above ...l touch 6:09 PM @ 57% 9- McDonald's grocery Deliveries are often managed by: * Manufacturer Storage with Direct Shipping Distributor Storage with Last Mile Delivery Distributor Storage with Carrier Delivery All of the above depending on the competitive strategy 10- The main advantage of a network with retail storage is: * Lower facility costs than other networks Lower delivery costs and faster response than other networks Higher delivery costs but more responsiveness than other networks Higher Logistics cost and more response time than other networks 11. The Internet allows McDonald's ...l touch 6:09 PM 57% 11- The Internet allows McDonald's customers to place an order at any suitable time: * Response Time Time to Market Customer Experience Flexible Pricing, Product Portfolio, and Promotions 12- Which of the following elements can be greatly affected by effective store replenishment: * Order Visibility Product Variety Product Availability All of the above 13- Having the example of McDonald's ...l touch 6:09 PM @ 57% 13- Having the example of McDonald's supply chain, the factors influencing network design decisions include: * Infrastructure factors Competitive factors & Logistics and facility costs Customer response time and local presence O All the above 14- As a supply chain manager at McDonald's when considering a new facility role your focus should be directed on: * Capacity allocation Markets and supply sources Main roles and processes Where the facility should be located 15- Having the example of McDonald's supply chain, the factors influencing ..ll touch 6:09 PM 2 1 57% 15- Having the example of McDonald's supply chain, the factors influencing network design decisions include: * Strategic & political factors Technological factors Macroeconomic factors All the above 16- McDonald's digital network will enable the company to: * Efficiently manage spending throughout its supply chain Keep low inventories Improve transportation Increase supply chain costs 17- When you drive thru McDonald's, this is Il touch 6:09 PM @ 1 57% 17- When you drive thru McDonald's, this is an example of which distribution network design: * Retail storage with customer pickup Manufacturer storage with direct shipping Distributor storage with last-mile delivery Distributor storage with carrier delivery 18- McDonald's applied supply chain technology on its suppliers within its distribution network through: * Low cost and high responsiveness Low cost and low responsiveness High cost and high responsiveness None of the above 19- McDonald's Supply chain network Il touch 6:09 PM 1 57% 19- McDonald's Supply chain network design decisions include the assignment of: Facility role Facility Location Capacity Allocation Market and Supply Chain allocation 20 - McDonald's can have wide variety of factors that influence its network design decisions in supply chains: * Strategic factors Technological factors Macroeconomic factors Infrastructure factors Page 1 of 1 Submit Never submit passwords through Google Forms