Question: im lost please help. last expert told me wrong stuff a. The process standard deviation is 0.10 ounces, and the process control is set at

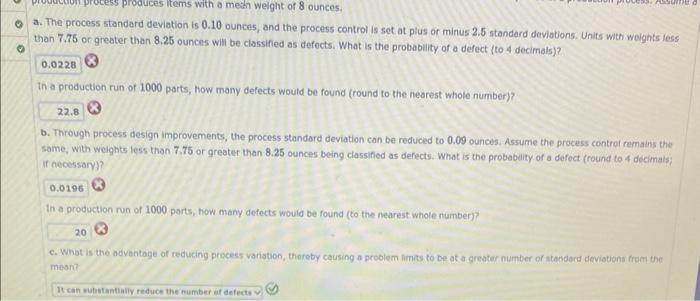

a. The process standard deviation is 0.10 ounces, and the process control is set at plus or minus 2.5 standard deviotions. Units with weights less than 7.75 or greater than 8.25 ounces will be classified as defects. What is the probability of a defect (to 4 decimais)? in a production run of 1000 parts, how many defects would be found (round to the nearest whole number)? b. Through process design improvements, the process standard deviation can be reduced to 0.09 ounces. Assume the process controi remains the same, with welghts less than 7.75 or greater than 8.25 ounces being classified as defects. What is the probability of a defect (round to 4 decimals; If necessary)? In a production run of 1000 ports, how many defects would be found (to the nearest whole number)? c. What is the adventage of reducing precess vanstion, thereby causing a problem imits to be at a greater number of atandacd deviotions from the meon

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts