Question: In a complex manufacturing process, four operations are performed in series. Because of the nature of the process, machines frequently fall out of adjustment and

In a complex manufacturing process, four operations are performed in series. Because of the nature of the process, machines frequently fall out of adjustment and must be repaired.

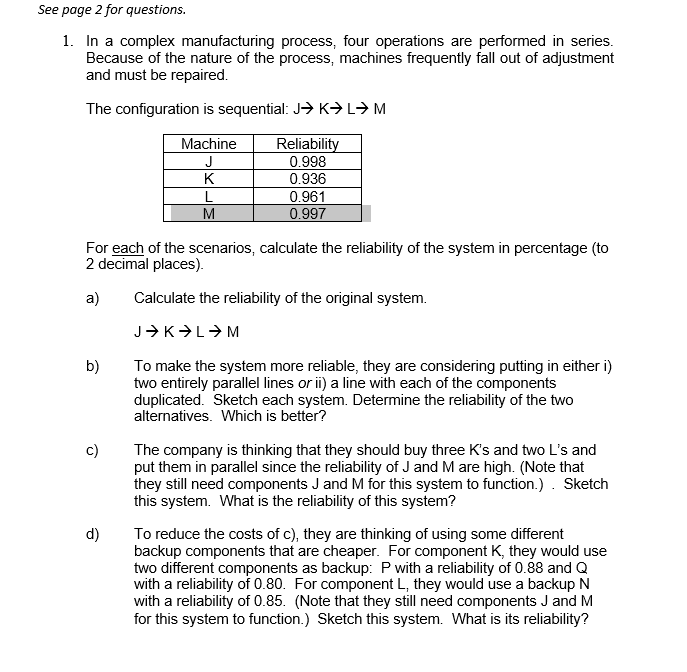

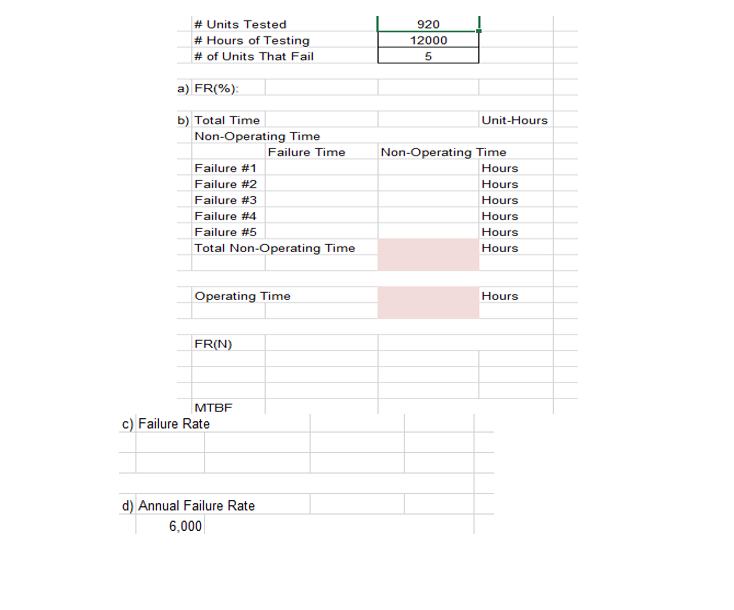

See page 2 for questions. 1. In a complex manufacturing process, four operations are performed in series. Because of the nature of the process, machines frequently fall out of adjustment and must be repaired. The configuration is sequential: K LM Machine J K L M Reliability 0.998 0.936 0.961 0.997 For each of the scenarios, calculate the reliability of the system in percentage (to 2 decimal places) a) Calculate the reliability of the original system. JKM b) c) To make the system more reliable, they are considering putting in either i) two entirely parallel lines or ii) a line with each of the components duplicated. Sketch each system. Determine the reliability of the two alternatives. Which is better? The company is thinking that they should buy three K's and two L's and put them in parallel since the reliability of J and M are high. (Note that they still need components J and M for this system to function.). Sketch this system. What is the reliability of this system? To reduce the costs of c), they are thinking of using some different backup components that are cheaper. For component K, they would use two different components as backup: P with a reliability of 0.88 and Q with a reliability of 0.80. For component L, they would use a backup N with a reliability of 0.85. (Note that they still need components J and M for this system to function.) Sketch this system. What is its reliability? d) # Units Tested # Hours of Testing # of Units That Fail 920 12000 5 a) FR(%) Unit-Hours b) Total Time Non-Operating Time Failure Time Failure #1 Failure #2 Failure #3 Failure #4 Failure #5 Total Non-Operating Time Non-Operating Time Hours Hours Hours Hours Hours Hours Operating Time Hours FR(N) MTBF c) Failure Rate d) Annual Failure Rate 6,000 See page 2 for questions. 1. In a complex manufacturing process, four operations are performed in series. Because of the nature of the process, machines frequently fall out of adjustment and must be repaired. The configuration is sequential: K LM Machine J K L M Reliability 0.998 0.936 0.961 0.997 For each of the scenarios, calculate the reliability of the system in percentage (to 2 decimal places) a) Calculate the reliability of the original system. JKM b) c) To make the system more reliable, they are considering putting in either i) two entirely parallel lines or ii) a line with each of the components duplicated. Sketch each system. Determine the reliability of the two alternatives. Which is better? The company is thinking that they should buy three K's and two L's and put them in parallel since the reliability of J and M are high. (Note that they still need components J and M for this system to function.). Sketch this system. What is the reliability of this system? To reduce the costs of c), they are thinking of using some different backup components that are cheaper. For component K, they would use two different components as backup: P with a reliability of 0.88 and Q with a reliability of 0.80. For component L, they would use a backup N with a reliability of 0.85. (Note that they still need components J and M for this system to function.) Sketch this system. What is its reliability? d) # Units Tested # Hours of Testing # of Units That Fail 920 12000 5 a) FR(%) Unit-Hours b) Total Time Non-Operating Time Failure Time Failure #1 Failure #2 Failure #3 Failure #4 Failure #5 Total Non-Operating Time Non-Operating Time Hours Hours Hours Hours Hours Hours Operating Time Hours FR(N) MTBF c) Failure Rate d) Annual Failure Rate 6,000

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts