Question: In a design exercise for a metal matrix composite to work at 400C without having any creep deformation, you have reached the conclusion of

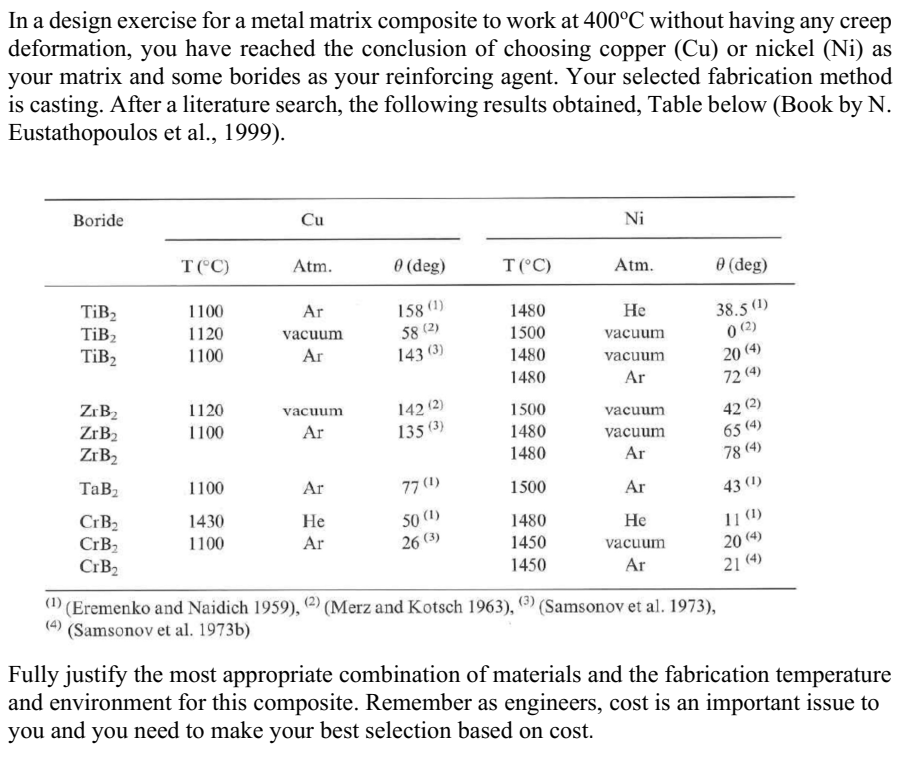

In a design exercise for a metal matrix composite to work at 400C without having any creep deformation, you have reached the conclusion of choosing copper (Cu) or nickel (Ni) as your matrix and some borides as your reinforcing agent. Your selected fabrication method is casting. After a literature search, the following results obtained, Table below (Book by N. Eustathopoulos et al., 1999). Boride TiB TiB TiB ZrB ZrB ZrB TaB2 CrB CrB CrB T (C) 1100 1120 1100 1120 1100 1100 1430 1100 Cu Atm. Ar vacuum Ar vacuum Ar Ar He Ar 0 (deg) 158 (1) 58 (2) 143 (3) 142 (2) 135 (3) 77 (1) 50 (1) 26 (3) T (C) 1480 1500 1480 1480 1500 1480 1480 1500 1480 1450 1450 Ni Atm. He vacuum vacuum Ar vacuum vacuum Ar Ar He vacuum Ar 0 (deg) 38.5 (1) 0 (2) 20 (4) 72 (4) 42 (2) 65 (4) 78 (4) 43 () 11 (1) 20 (4) 21 (4) (1) (Eremenko and Naidich 1959), (2) (Merz and Kotsch 1963), (3) (Samsonov et al. 1973), (Samsonov et al. 1973b) Fully justify the most appropriate combination of materials and the fabrication temperature and environment for this composite. Remember as engineers, cost is an important issue to you and you need to make your best selection based on cost. In a design exercise for a metal matrix composite to work at 400C without having any creep deformation, you have reached the conclusion of choosing copper (Cu) or nickel (Ni) as your matrix and some borides as your reinforcing agent. Your selected fabrication method is casting. After a literature search, the following results obtained, Table below (Book by N. Eustathopoulos et al., 1999). Boride TiB TiB TiB ZrB ZrB ZrB TaB2 CrB CrB CrB T (C) 1100 1120 1100 1120 1100 1100 1430 1100 Cu Atm. Ar vacuum Ar vacuum Ar Ar He Ar 0 (deg) 158 (1) 58 (2) 143 (3) 142 (2) 135 (3) 77 (1) 50 (1) 26 (3) T (C) 1480 1500 1480 1480 1500 1480 1480 1500 1480 1450 1450 Ni Atm. He vacuum vacuum Ar vacuum vacuum Ar Ar He vacuum Ar 0 (deg) 38.5 (1) 0 (2) 20 (4) 72 (4) 42 (2) 65 (4) 78 (4) 43 () 11 (1) 20 (4) 21 (4) (1) (Eremenko and Naidich 1959), (2) (Merz and Kotsch 1963), (3) (Samsonov et al. 1973), (Samsonov et al. 1973b) Fully justify the most appropriate combination of materials and the fabrication temperature and environment for this composite. Remember as engineers, cost is an important issue to you and you need to make your best selection based on cost.

Step by Step Solution

There are 3 Steps involved in it

If Service temperature is above will fail due to for Ni SO So AS for for ... View full answer

Get step-by-step solutions from verified subject matter experts