Question: In a factory, there is a batch production system consisting of four workstations: Workstation A , B , C , and D . Below is

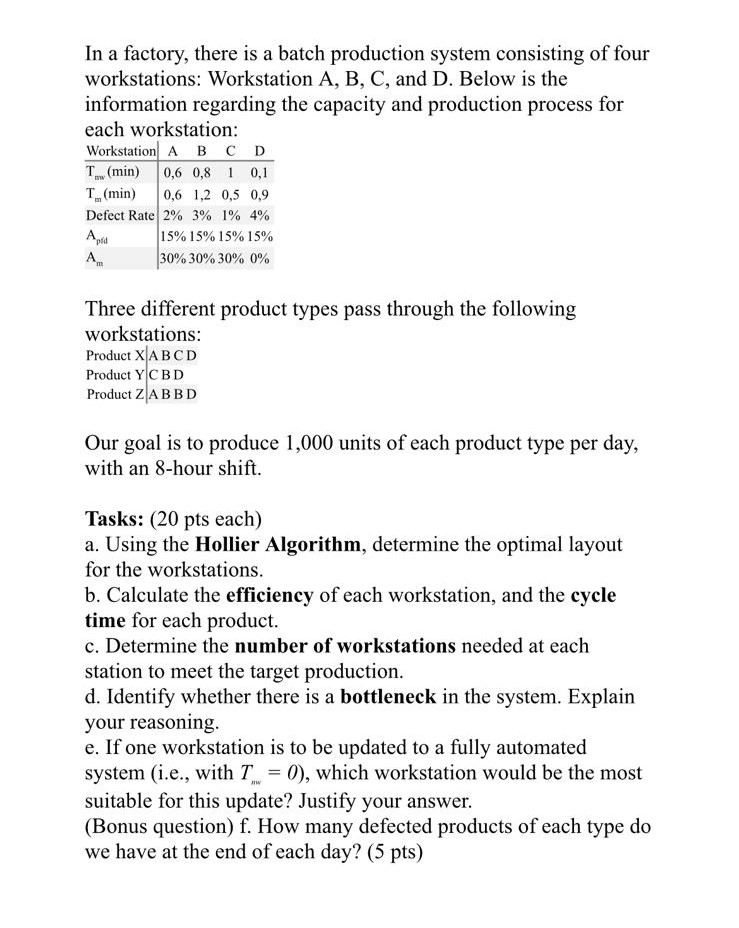

In a factory, there is a batch production system consisting of four

workstations: Workstation A B C and D Below is the

information regarding the capacity and production process for

each workstation:

Three different product types pass through the following

workstations:

Product XABCD

Product YCBD

Product ZABBD

Our goal is to produce units of each product type per day,

with an hour shift.

Tasks: pts each

a Using the Hollier Algorithm, determine the optimal layout

for the workstations.

b Calculate the efficiency of each workstation, and the cycle

time for each product.

c Determine the number of workstations needed at each

station to meet the target production.

d Identify whether there is a bottleneck in the system. Explain

your reasoning.

e If one workstation is to be updated to a fully automated

system ie with Tn which workstation would be the most

suitable for this update? Justify your answer.

Bonus question f How many defected products of each type do

we have at the end of each day? pts also need to use this formula TstdTnw ApfdTm Am

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock