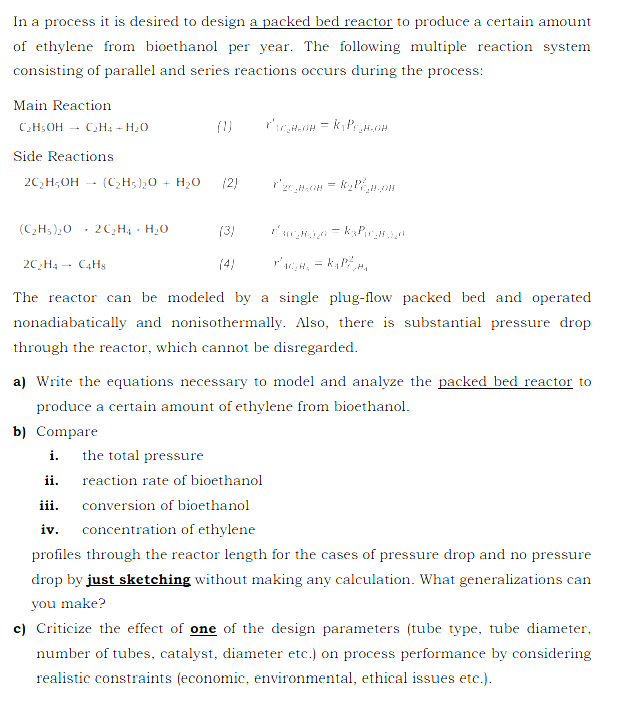

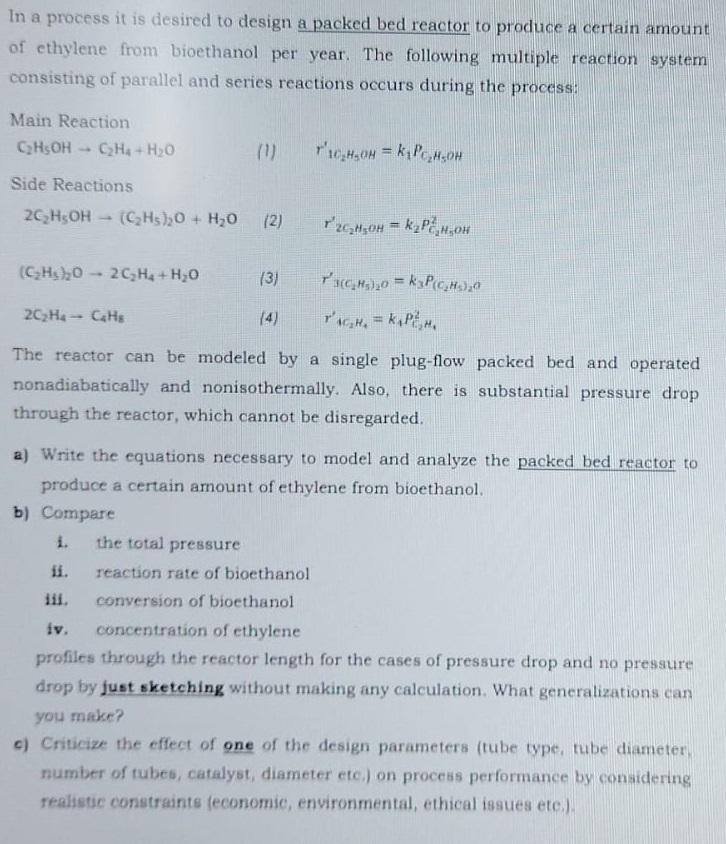

Question: In a process it is desired to design a packed bed reactor to produce a certain amount of ethylene from bioethanol per year. The following

In a process it is desired to design a packed bed reactor to produce a certain amount of ethylene from bioethanol per year. The following multiple reaction system consisting of parallel and series reactions occurs during the process: Main Reaction CHOH CH:-HO r. = K Pro Side Reactions 2C,H,OH (CH3)2 + H2O 2) 2204 = KP.COM (GH), 2CH.H.0 (3) Mark PM PICHA = kap 2CH: -- CHS HA The reactor can be modeled by a single plug-flow packed bed and operated nonadiabatically and nonisothermally. Also, there is substantial pressure drop through the reactor, which cannot be disregarded. a) Write the equations necessary to model and analyze the packed bed reactor to produce a certain amount of ethylene from bioethanol. b) Compare i. the total pressure ii. reaction rate of bioethanol iii. conversion of bioethanol iv. concentration of ethylene profiles through the reactor length for the cases of pressure drop and no pressure drop by just sketching without making any calculation. What generalizations can you make? c) Criticize the effect of one of the design parameters (tube type, tube diameter, number of tubes, catalyst, diameter etc.) on process performance by considering realistic constraints (economic, environmental, ethical issues etc.). In a process it is desired to design a packed bed reactor to produce a certain amount of ethylene from bioethanol per year. The following multiple reaction system consisting of parallel and series reactions occurs during the process Main Reaction CH OH GH+H2O 7100 = k PC,H,OH Side Reactions 2CH3OH - (C2H5 ) + H2O 12) PP2CM30H = k PC,H,OH (GH), 2CH4+H2O (3) TIM),0 = k PCH), 2CH - CHE (4) The reactor can be modeled by a single plug-flow packed bed and operated nonadiabatically and nonisothermally. Also, there is substantial pressure drop through the reactor, which cannot be disregarded. a) Write the equations necessary to model and analyze the packed bed reactor to produce a certain amount of ethylene from bioethanol. b) Compare i. the total pressure reaction rate of bioethanol conversion of bioethanol iv. concentration of ethylene profiles through the reactor length for the cases of pressure drop and no pressure drop by just sketching without making any calculation. What generalizations can you make? c) Criticize the effect of one of the design parameters (tube type, tube diameter, number of tubes, catalyst, diameter etc.) on process performance by considering realistic constraints (economie, environmental, ethical issues etc.)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts