Question: In Table 2 , multiple parameters were changed across different equipment pieces, and some have more of an effect than others. . The first conclusion

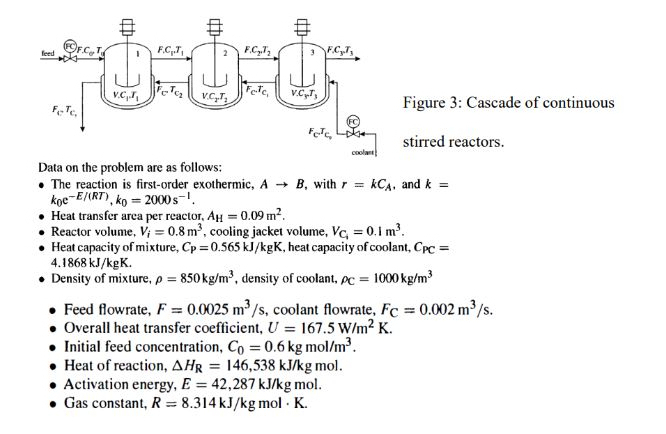

In Table multiple parameters were changed across different equipment pieces, and some have more of an effect than others. The first conclusion from this table is the parameter changes that decrease the power output, including decreasing the mass flow rate and the pressure change. All the data are included: Figure : Cascade of continuous

stirred reactors.

Data on the problem are as follows:

The reaction is firstorder exothermic, with and

Heat transfer area per reactor,

Reactor volume, cooling jacket volume,

Heat capacity of mixture, heat capacity of coolant,

Density of mixture, density of coolant,

Feed flowrate, coolant flowrate,

Overall heat transfer coefficient,

Initial feed concentration, kgmo

Heat of reaction, mol.

Activation energy, gmol.

Gas constant, gmol

State modelling assumptions and indicate balance boundaries.

Develop the mathematical model with mass and energy balance. explain the development states.

Develop a steady state model in matlab.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock