Question: In the lowest-cost plan by adding a new plant, how much capacity is used in plant 1? A. 400 B. 350 C. 250 D. 0

In the lowest-cost plan by adding a new plant, how much capacity is used in plant 1?

A. 400

B. 350

C. 250

D. 0

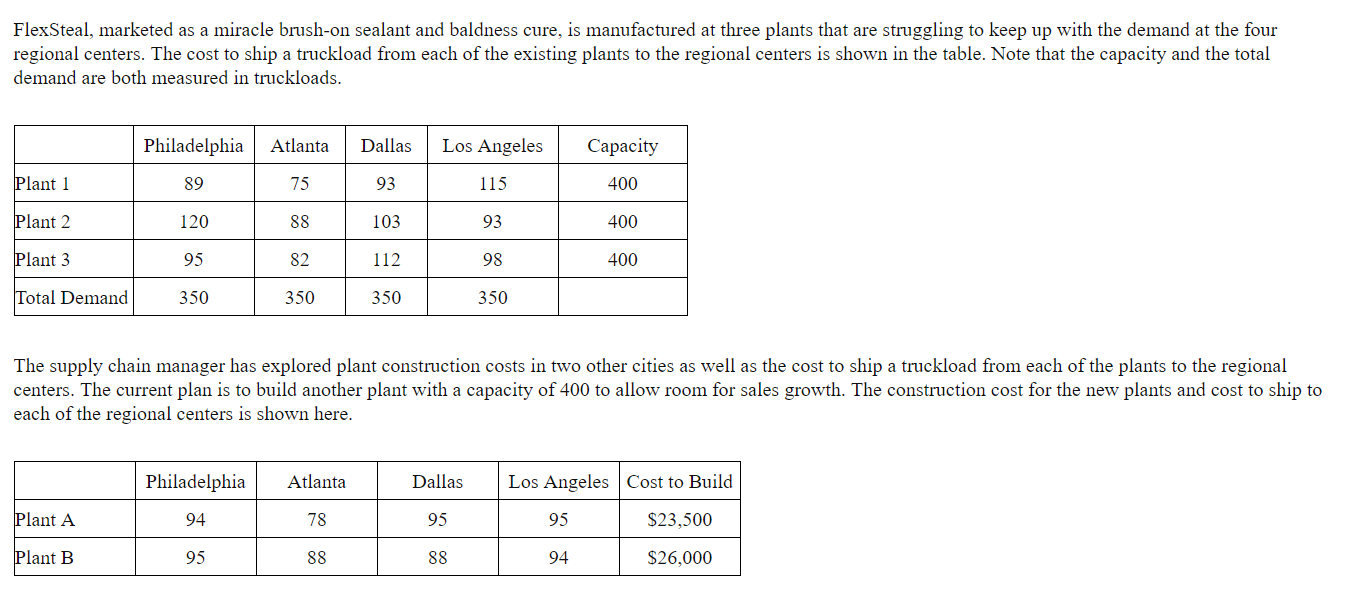

FlexSteal, marketed as a miracle brush-on sealant and baldness cure, is manufactured at three plants that are struggling to keep up with the demand at the four regional centers. The cost to ship a truckload from each of the existing plants to the regional centers is shown in the table. Note that the capacity and the total demand are both measured in truckloads. Philadelphia Atlanta Dallas Capacity Plant 1 89 75 93 400 Los Angeles 115 93 98 Plant 2 120 88 103 400 Plant 3 95 82 112 400 Total Demand 350 350 350 350 The supply chain manager has explored plant construction costs in two other cities as well as the cost to ship a truckload from each of the plants to the regional centers. The current plan is to build another plant with a capacity of 400 to allow room for sales growth. The construction cost for the new plants and cost to ship to each of the regional centers is shown here. Philadelphia | Atlanta Dallas Los Angeles Cost to Build Plant A 94 78 95 95 $23,500 Plant B 95 88 - 88 94 $26,000Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock