Question: In this case study you are asked to develop a COGS (cost) estimate for casting a 1.5 kg spherical ingot of pure Sn using what

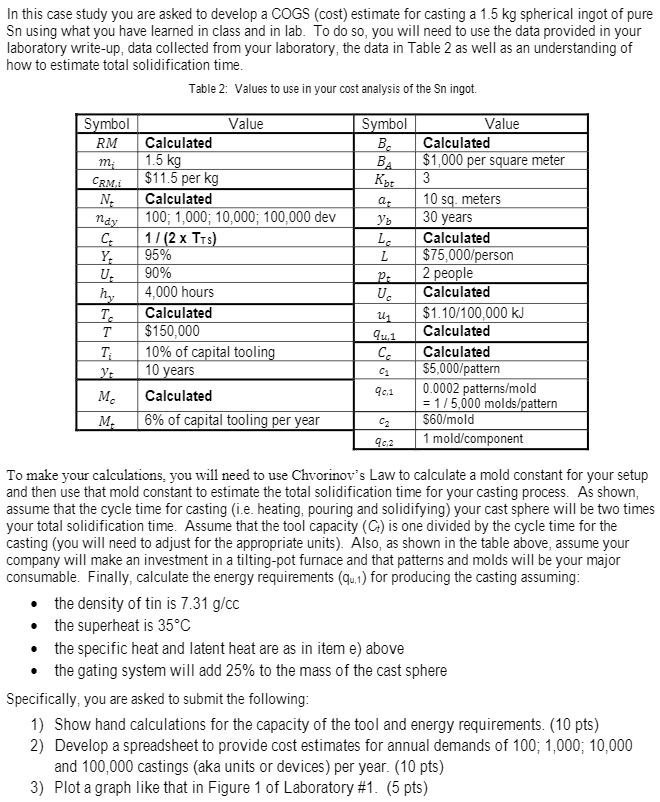

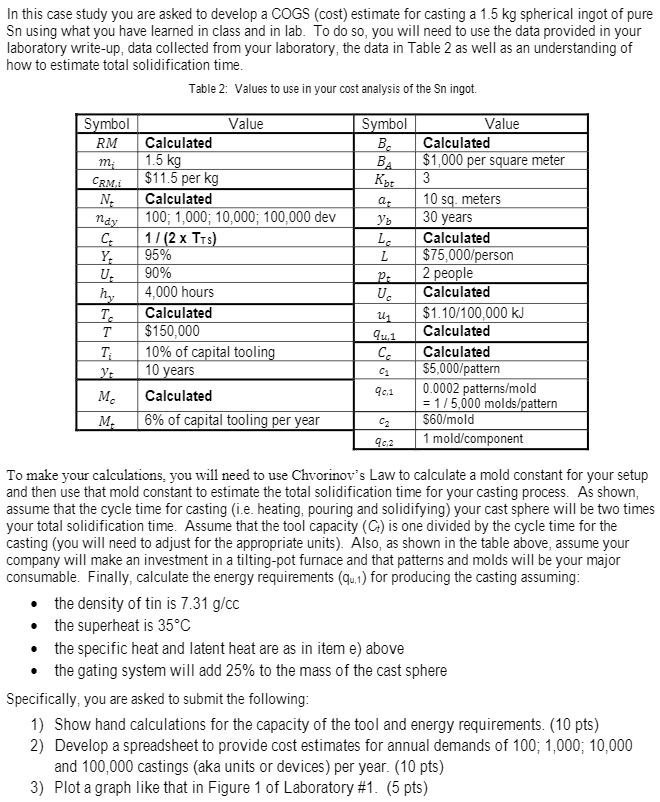

In this case study you are asked to develop a COGS (cost) estimate for casting a 1.5 kg spherical ingot of pure Sn using what you have learned in class and in lab. To do so, you will need to use the data provided in your laboratory write-up, data collected from your laboratory, the data in Table 2 as well as an understanding of how to estimate total solidification time. Table 2: Values to use in your cost analysis of the Sn ingot. Symbol Value B. Calculated BA $1,000 per square meter Kot 3 at 10 sq. meters ndy yo 30 years Symbol Value RM Calculated mi 1.5 kg CRM. $11.5 per kg N. Calculated 100; 1,000; 10,000; 100,000 dev C 17(2 x TTs) Y. 95% U. 90% hy 4,000 hours T. Calculated T $150,000 Ti 10% of capital tooling yt 10 years M Calculated M. 6% of capital tooling per year Lc L P. Uc 41 92.1 Cc C1 Calculated $75,000/person 2 people Calculated $1.10/100,000 kJ Calculated Calculated $5,000/pattern 0.0002 patterns/mold = 1/5,000 molds/pattern $60/mold 1 mold/component 90,1 90.2 To make your calculations, you will need to use Chvorinov's Law to calculate a mold constant for your setup and then use that mold constant to estimate the total solidification time for your casting process. As shown, assume that the cycle time for casting (i.e. heating, pouring and solidifying) your cast sphere will be two times your total solidification time. Assume that the tool capacity (C) is one divided by the cycle time for the casting (you will need to adjust for the appropriate units). Also, as shown in the table above, assume your company will make an investment in a tilting-pot furnace and that patterns and molds will be your major consumable. Finally, calculate the energy requirements (qu.1) for producing the casting assuming: the density of tin is 7.31 g/cc the superheat is 35C the specific heat and latent heat are as in item e) above the gating system will add 25% to the mass of the cast sphere Specifically, you are asked to submit the following: 1) Show hand calculations for the capacity of the tool and energy requirements. (10 pts) 2) Develop a spreadsheet to provide cost estimates for annual demands of 100; 1,000; 10,000 and 100,000 castings (aka units or devices) per year. (10 pts) 3) Plot a graph like that in Figure 1 of Laboratory #1. (5 pts) In this case study you are asked to develop a COGS (cost) estimate for casting a 1.5 kg spherical ingot of pure Sn using what you have learned in class and in lab. To do so, you will need to use the data provided in your laboratory write-up, data collected from your laboratory, the data in Table 2 as well as an understanding of how to estimate total solidification time. Table 2: Values to use in your cost analysis of the Sn ingot. Symbol Value B. Calculated BA $1,000 per square meter Kot 3 at 10 sq. meters ndy yo 30 years Symbol Value RM Calculated mi 1.5 kg CRM. $11.5 per kg N. Calculated 100; 1,000; 10,000; 100,000 dev C 17(2 x TTs) Y. 95% U. 90% hy 4,000 hours T. Calculated T $150,000 Ti 10% of capital tooling yt 10 years M Calculated M. 6% of capital tooling per year Lc L P. Uc 41 92.1 Cc C1 Calculated $75,000/person 2 people Calculated $1.10/100,000 kJ Calculated Calculated $5,000/pattern 0.0002 patterns/mold = 1/5,000 molds/pattern $60/mold 1 mold/component 90,1 90.2 To make your calculations, you will need to use Chvorinov's Law to calculate a mold constant for your setup and then use that mold constant to estimate the total solidification time for your casting process. As shown, assume that the cycle time for casting (i.e. heating, pouring and solidifying) your cast sphere will be two times your total solidification time. Assume that the tool capacity (C) is one divided by the cycle time for the casting (you will need to adjust for the appropriate units). Also, as shown in the table above, assume your company will make an investment in a tilting-pot furnace and that patterns and molds will be your major consumable. Finally, calculate the energy requirements (qu.1) for producing the casting assuming: the density of tin is 7.31 g/cc the superheat is 35C the specific heat and latent heat are as in item e) above the gating system will add 25% to the mass of the cast sphere Specifically, you are asked to submit the following: 1) Show hand calculations for the capacity of the tool and energy requirements. (10 pts) 2) Develop a spreadsheet to provide cost estimates for annual demands of 100; 1,000; 10,000 and 100,000 castings (aka units or devices) per year. (10 pts) 3) Plot a graph like that in Figure 1 of Laboratory #1. (5 pts)