Question: In this project, you will create a dynamic systems model for inventory control in an automobile supply chain. Consider a supply chain consisting of 3

In this project, you will create a dynamic systems model for inventory control in an automobile supply chain.

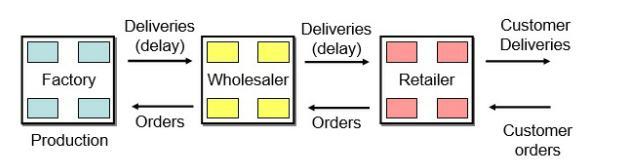

Consider a supply chain consisting of 3 phases: A factory, a wholesaler, and a retailer. Customers place orders at the retailer. The retailer, in turn, orders cars from the wholesaler, and the wholesaler orders cars from the factory. There is a delay in each phase of the order.

In this project, you will create a dynamic systems model of the supply chain and compare different types of control models.

You should make the following assumptions about the system dynamics.

- Customer orders initially arrive at a rate of 5 per day, then change to a rate of 10 per day after30 days.

- There is a 5-day delay for the wholesaler to deliver a car to the retailer, once it is ordered.

- There is a 4-week delay for the factory to produce and deliver a car to the wholesaler, once it is ordered.

- The retailer, wholesaler, and factory each have a target inventory of 100 cars.

Your report should containthe following sections:

- Introduction and background

- Model description

- Give a block-diagram model (Simulink) of the system. In the block diagram, labeleach arc describing what the arc represents.

- Explain your model and diagram.What do different parts of the model represent?

- Make sure that your model is large enough to read (you may want to display differentparts of the model separately and explain each part).

- Discuss any assumptions made in your model.

- Analysis of model

- Plot the inventorylevels over time for the dealer, wholesaler, and factory.

- Compare results for two different kinds of control models (proportional, PD, PID, etc.) You may choosewhich two controlmodels you analyze.

- Conduct a sensitivity analysis to show how results change with different control gain values. Discusstradeoffs for different control gains (response times, presenceof oscillations, steady-state error).

- Conclusion. State your main findings, insights, and limitations of the work. What analysis would you recommend to a futureteam for continuing your work?

Factory Production Deliveries (delay) Orders Wholesaler Deliveries (delay) Orders Retailer Customer Deliveries Customer orders

Step by Step Solution

3.43 Rating (159 Votes )

There are 3 Steps involved in it

Creating a dynamic systems model for inventory control in an automobile supply chain involves several steps and considerations Lets break down the req... View full answer

Get step-by-step solutions from verified subject matter experts