Question: Individual Project Due Date: 1 0 : 0 0 AM , Tuesday, April 3 0 , 2 0 2 4 A company operates a Sawmill

Individual Project

Due Date: : AM Tuesday, April

A company operates a Sawmill to cut and process the logs harvested from Appalachian Mountains. You are asked to assess the data collected by the company and recommend specific statistical process techniques and methods that will improve the quality of products and help save money by eliminating andor avoiding loss associated with poor quality.

Sawing

Before the log is presented to the headrig for breakdown, it is cut to the longest permissible straight length with a cutoff saw, whereupon it is loaded onto the headsaw carriage and positioned in such a manner as to allow the operator to achieve a sawing pattern, which will result in the optimum production of sawn timber with the minimum of waste. The pattern of cut is largely determined by the dimension and condition of the log as well as the market requirements for the widths and thicknesses of the lumber.

Once debarked, sawing of the log is achieved by the use of a circular saw Figure A log carriage conveys the log through the headsaw on which the log may be clamped and turned, so as to enable it to be presented to the headsaw in order to achieve the best sawing pattern. Following the headrig, further breakdown of slabs, flitches and cants takes place in the resaw, which enables the wood to be upgraded; thick slabs being sawn into planks and the flitches and cants sawn into planks and boards. The rough round edges of the pieces coming from the headrig and resaws are removed by either a circular saw or chipper edger to produce standardized widths as required. On leaving the headrig, resaw or edger, the lumber is cut to standardized lengths, edges squared, and defects removed using one or more fixed or moveable trimming saws, whereupon the lumber Figure proceeds to be sorted and graded.

Sorting and Grading

The sawn and trimmed timber is sorted according to thickness, width, length, quality, grade, and species depending on the market requirements; such an activity may be undertaken manually or in the case of mills where lowcost labor is not available, by mechanized sorters. Grading is a means to segregate the lumber according to the overall quality, direction of grain, presence of knots and defects, general appearance, and other factors.

To protect the lumber against attack from fungi and insects, the ends may be brushed manually or mechanically dipped in a suitably prepared chemical solution. Wax or paint is applied to the endgrain of lumber to be airdried, either by brush or spraying, to act as a sealant to bring about a slower drying of the extremities and hence, give rise to a more uniform drying of the lumber.

Drying

To protect the lumber against attack from fungi and insects, the ends may be brushed manually or mechanically dipped in a suitably prepared chemical solution. Wax or paint is applied to the endgrain of lumber to be airdried, either by brush or spraying, to act as a sealant to bring about a slower drying of the extremities and hence, give rise to a more uniform drying of the lumber.

Drying

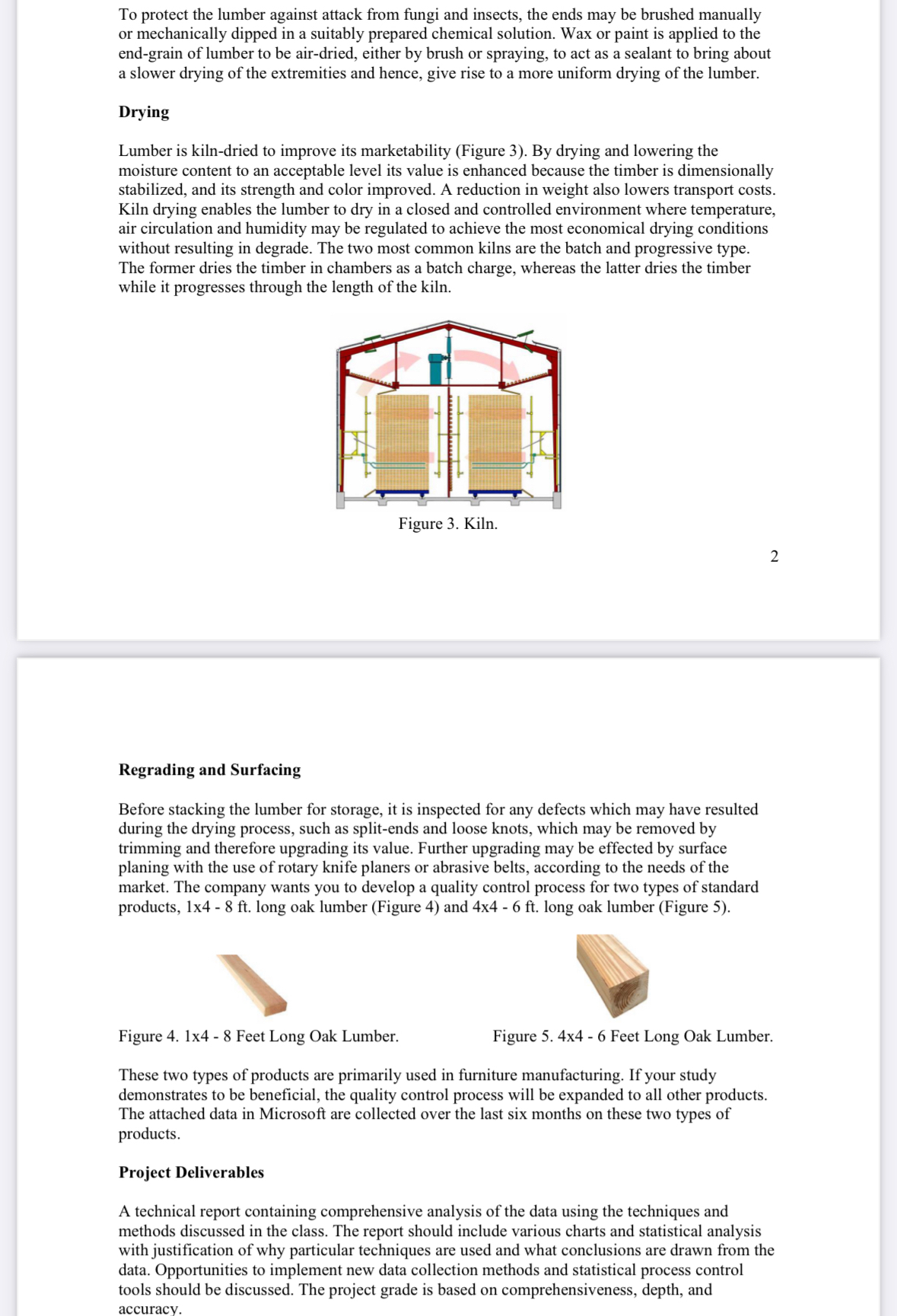

Lumber is kilndried to improve its marketability Figure By drying and lowering the moisture content to an acceptable level its value is enhanced because the timber is dimensionally stabilized, and its strength and color improved. A reduction in weight also lowers transport costs. Kiln drying enables the lumber to dry in a closed and controlled environment where temperature, air circulation and humidity may be regulated to achieve the most economical drying conditions without resulting in degrade. The two most common kilns are the batch and progressive type. The former dries the timber in chambers as a batch charge, whereas the latter dries the timber while it progresses through the length of the kiln.

Regrading and Surfacing

Before stacking the lumber for storage, it is inspected for any defects which may have resulted during the drying process, such as splitends and loose knots, which may be removed by trimming and therefore upgrading its value. Further upgrading may be effected by surface planing with the use of rotary knife planers or abrasive belts, according to the needs of the market. The company wants you to develop a quality control process for two types of standard products, long oak lumber Figure and long oak lumber Figure

Figure x Feet Long Oak Lumber.

Figure x Feet Long Oak Lumber.

These two types of products are primarily used in furniture manufacturing. If your study demonstrates to be beneficial, the quality control process will be expanded to all other products. The attached data in Microsoft are collected over the last six months on these two types of products.

Project Deliverables

A technical report containing comprehensive analysis of the data using the techniques and methods di

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock