Question: INFO & QUESTION IN PHOTOS: Develop an MRP planning schedule showing gross and net requirements in order release and order receipt dates To simplify data

INFO & QUESTION IN PHOTOS:

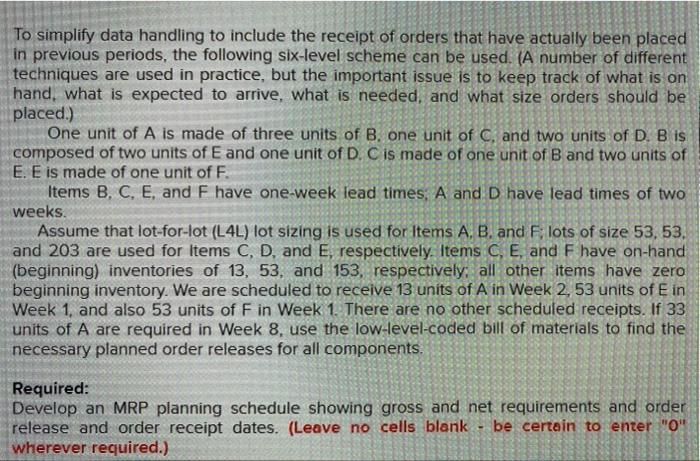

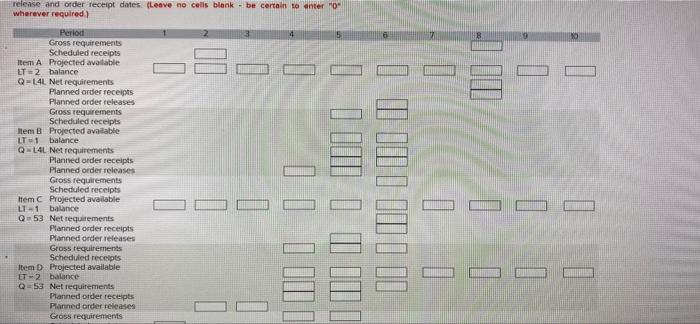

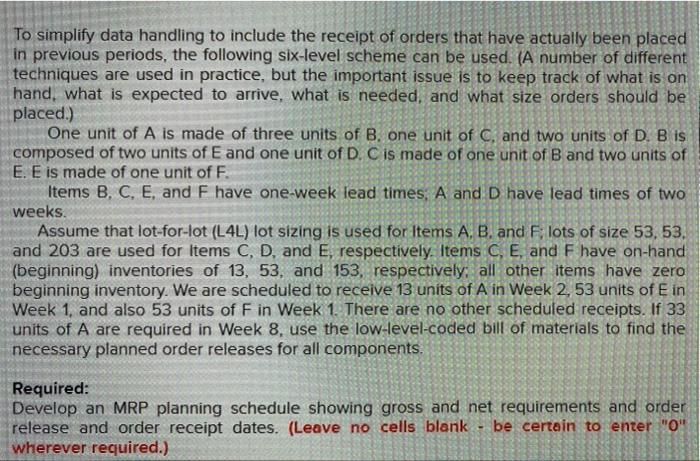

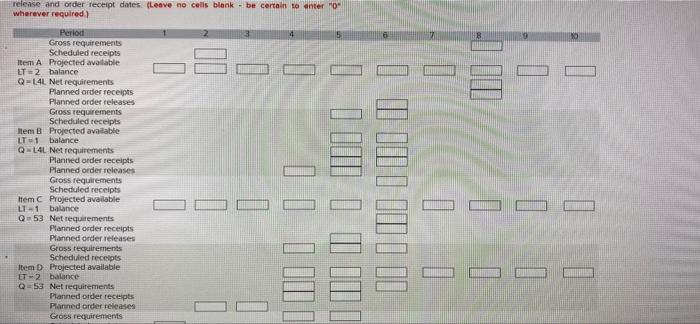

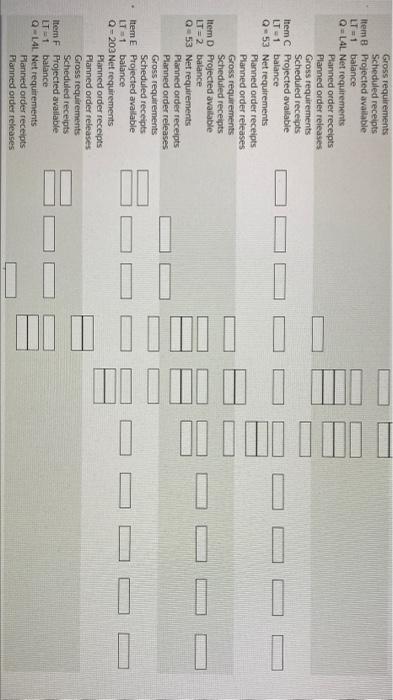

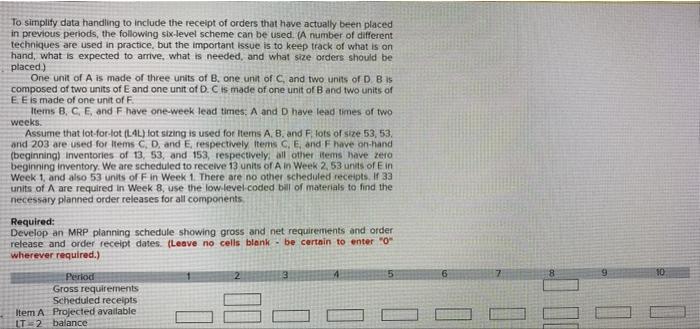

To simplify data handling to include the receipt of orders that have actually been placed in previous periods, the following six-level scheme can be used. (A number of different techniques are used in practice, but the important issue is to keep track of what is on hand, what is expected to arrive, what is needed, and what size orders should be placed.) One unit of A is made of three units of B. one unit of C, and two units of D. B is composed of two units of E and one unit of D. C is made of one unit of B and two units of E. E is made of one unit of F. Items B, C, E, and F have one-week lead times, A and D have lead times of two weeks. Assume that lot-fo lot (L4L) lot sizing is used for Items A, B, and lots of size 53, 53, and 203 are used for Items C, D, and E, respectively. Items C, E, and F have on-hand (beginning) inventories of 13, 53, and 153, respectively, all other items have zero beginning inventory. We are scheduled to receive 13 units of A in Week 2,53 units of E in Week 1, and also 53 units of F in Week 1. There are no other scheduled receipts. If 33 units of A are required in Week 8, use the low-level-coded bill of materials to find the necessary planned order releases for all components Required: Develop an MRP planning schedule showing gross and net requirements and order release and order receipt dates. (Leave no cells blank be certain to enter "0" wherever required.) release and order receipt dates (Leave no cells blank - be certain to enter 0 wherever required) Period Gross requirements Scheduled receipts Item A Projected available LT=2 balance Q=1.4L Net requirements Planned order receipts Planned order releases Gross requirements Scheduled receipts Item B Projected available L1 balance Q-L4L Net requirements Planned order receipts Planned order releases Gross requirements Scheduled receipts Hem C Projected available LT-1 balance Q53 Net requirements Planned order receipts Planned order releases Gross requirements Scheduled receipts Item D Projected available ET-2 balance Q=53 Net requirements Planned order receipts Planned order releases Gross requirements I 11 1 1 1 1 1 u II I II III u 111 I I C I I O 0 - Gross requirements Scheduled receipts Item 8 Projected available LT=1 balance Q-LAL Net requirements Planned order receipts Planned order releases Gross requirements Scheduled receipts Item C Projected available LT = 1 balance Q-53 Net requirements Planned order receipts Planned order releases Gross requirements Scheduled receipts Item D Projected available LT=2 balance Q53 Net requirements Planned order receipts Planned order releases Gross requirements Scheduled receipts Item E Projected available LT=1 balance Q-203 Net requirements Planned order receipts Planned order releases Gross requirements Scheduled receipts Item F Projected available LT=1 balance Q-LAL Net requirements Flanned order receipts Planned order releases TI I II I IMI I DI I TI I II I TIN C . I I 11 OO DO To simplify data handling to include the receipt of orders that have actually been placed in previous periods, the following six-level scheme can be used. (A number of different techniques are used in practice, but the important issue is to keep track of what is on hand, what is expected to arrive, what is needed, and what size orders should be placed) One unit of A is made of three units of B, one unit of C, and two units of D BIS composed of two units of E and one unit of D. C is made of one unit of B and two units of E. E is made of one unit of F. Items B, C, E, and F have one week lead times: A and D have lead times of two weeks. Assume that lot-for-lot (LAL) lot sizing is used for Items A. B. and F. lots of size 53, 53, and 203 are used for Items C. D. and respectively items. E, and have on-hand (beginning) Inventories of 13, 53, and 153, respectively all other lems have zero beginning inventory. We are scheduled to receive 13 units of A in Week 2,53 units of Ein Week 1, and also 53 units of F in Week 1 There are no other scheduled receipts. If 33 units of A are required in Week 8, use the low level-coded bill of materials to find the necessary planned order releases for all components Required: Develop an MRP planning schedule showing gross and net requirements and order release and order receipt dates. (Leave no cells blank - be certain to enter "0" wherever required.) 30 . Period Gross requirements Scheduled receipts Item A Projected available LT 2 balance

Develop an MRP planning schedule showing gross and net requirements in order release and order receipt dates

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock