Question: INSTRUCTIONS NOTE: To make your calculations as straightforward as possible in the following exercises, assume unless stated otherwise that: 1. There are sufficient parts or

INSTRUCTIONS NOTE: To make your calculations as straightforward as possible in the following exercises, assume unless stated otherwise that:

1. There are sufficient parts or raw materials, so tasks are never starved. 2. Task times have negligible variability and, over time, workers neither speed up nor slow down. 3. There are no machine breakdowns or maintenance. 4. When there are buffers shown in process flow diagrams, they are large enough to accommodate any amount of work in process (WIP). 5. Travel time and time to transport parts from one operation to another are negligible. 6. All operations run with 100% yield; that is, the operations produce no defective units. 7. All processes are in steady state; thus, you may ignore any startup effects.

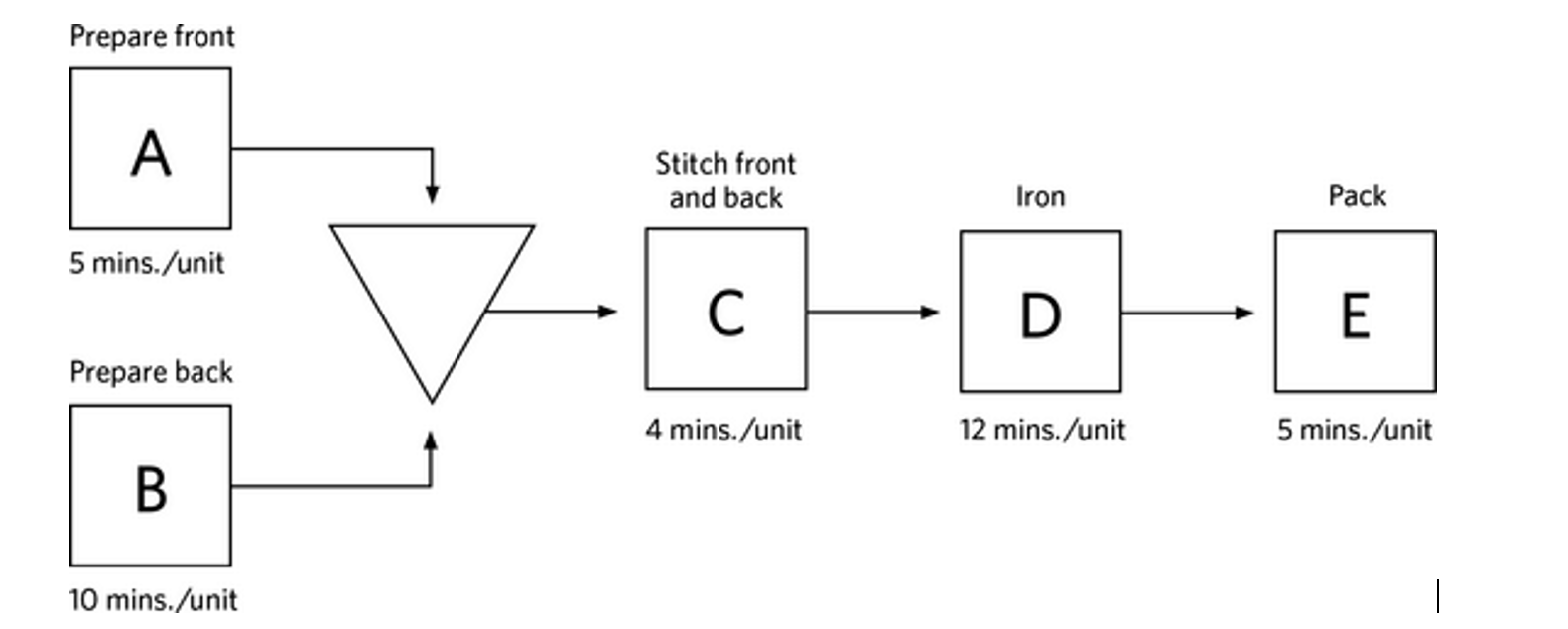

Process Flow Diagram for Making a Shirt

Consider the following process flow diagram for making a shirt. All steps (A, B, C, D, and E) are necessary to create each finished unit (shirt). Each step employs a single worker. Exact task times, in minutes/unit, are shown at each step. For example, it takes exactly 4 minutes to stitch the front and back of the shirt.

- Refer to the Process Flow Diagram for Making a Shirt. Consider only the task of preparing the front, task A, in isolation from the rest of the process. What is task As cycle time?

- Refer to the Process Flow Diagram for Making a Shirt. Consider the entire system (all steps). What is the entire systems minimum cycle time?

- Refer to the Process Flow Diagram for Making a Shirt. What is the minimum throughput time, that is, the fastest a rush order for one unit can go through the process?

- Refer to the Process Flow Diagram for Making a Shirt. Assume that the process operates eight hours a day. What is its daily capacity, in units per day?

- Refer to the Process Flow Diagram for Making a Shirt. Assume that the entire process is running at bottleneck pacing. Consider only the task of preparing the front, task A, in isolation from the rest of the process. What is the approximate labor utilization at task A?

- Refer to the Process Flow Diagram for Making a Shirt. During the day, what is the average labor utilization of all five workers?

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts