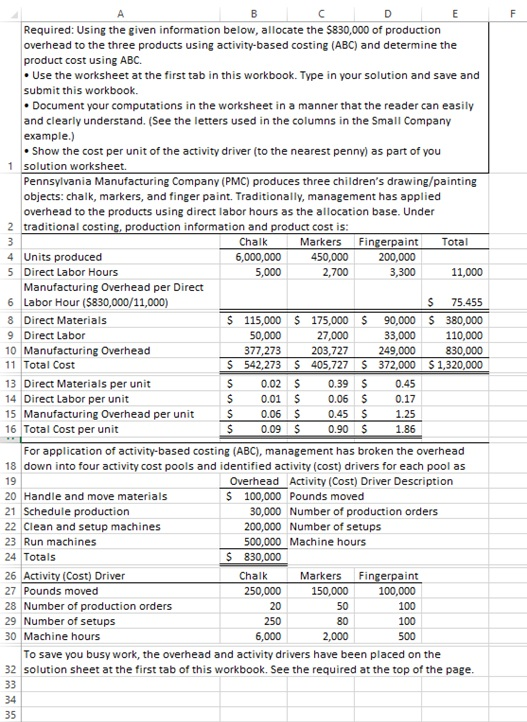

Question: Instructions: Overhead Activity Drivers: Activity Center Overhead (a) Chalk (b) Markers (c) Fingerpaint (d) Handle and move materials 100,000 250,000 150,000 100,000 Schedule production 30,000

Instructions:

Instructions:

Overhead Activity Drivers:

| Activity Center | Overhead (a) | Chalk (b) | Markers (c) | Fingerpaint (d) |

| Handle and move materials | 100,000 | 250,000 | 150,000 | 100,000 |

| Schedule production | 30,000 | 20 | 50 | 100 |

| Clean and setup machines | 200,000 | 250 | 80 | 100 |

| Run machines | 500,000 | 6,000 | 2,000 | 500 |

| Totals | 830,000 |

Required: Using the given information below, allocate the $830,000 of production overhead to the three products using activity-based costing (ABC) and determine the product cost using ABC. Use the worksheet at the first tab in this workbook. Type in your solution and save and submit this workbook. Document your computations in the worksheet in a manner that the reader can easily and clearly understand. (See the letters used in the columns in the Small Company example.) Show the cost per unit of the activity driver (to the nearest penny) as part of you 1 solution worksheet. Pennsylvania Manufacturing Company (PMC) produces three children's drawing/painting objects: chalk, markers, and finger paint. Traditionally, management has applied overhead to the products using direct labor hours as the allocation base. Under 2 traditional costing, production information and product cost is Markers Fingerpaint Total 4 Units produced 5 Direct Labor Hours 6,000,000 5,000 50,000 200,000 3,300 11,000 Manufacturing Overhead per Direct Labor Hour ($830,000/11,000) 8 Direct Materials 9 Direct Labor 10 Manufacturing Overhead 11 Total Cost 13 Direct Materials per unit 14 Direct Labor per unit 15 Manufacturing Overhead per unit 16 Total Cost per unit S 75.455 S 115,000 S 175,000 $ 90,000 S 380,000 33,000 110,000 830,000 $ 542,273 405,727 S 372,000 $1,320,000 50,000 377,273 27,000 203,727 249,000 $0.02 0.39 S 0.45 $ 0.01 0.06S 0.17 $0.06 0.41.25 $ 0.09 0.90 1.86 For application of activity-based costing (ABC), management has broken the overhead 18 down into four activity cost pools and identified activity (cost) drivers for each pool as 19 20 Handle and move materials Overhead S 100,000 Pounds moved Activity (Cost) Driver Description 1 Schedule production 22 Clean and setup machines 23 Run machines 24 Totals 26 Activity (Cost) Driver 27 Pounds moved 28 Number of production orders 29 Number of setups 30 Machine hours 30,000 Number of production orders 200,000 Number of setups 500,000 Machine hours S 830,000 Markers Fingerpaint 100,000 100 100 500 Chalk 250,000 20 250 6,000 150,000 50 80 2,000 To save you busy work, the overhead and activity drivers have been placed on the 32 solution sheet at the first tab of this workbook. See the required at the top of the page 34 35

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts