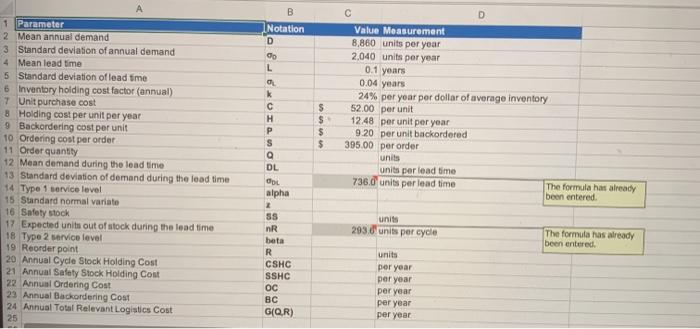

Question: inventory forecast analytic D B Notation D Op L O k H P C Value Measurement 8,860 units per year 2.040 units per year 0.1

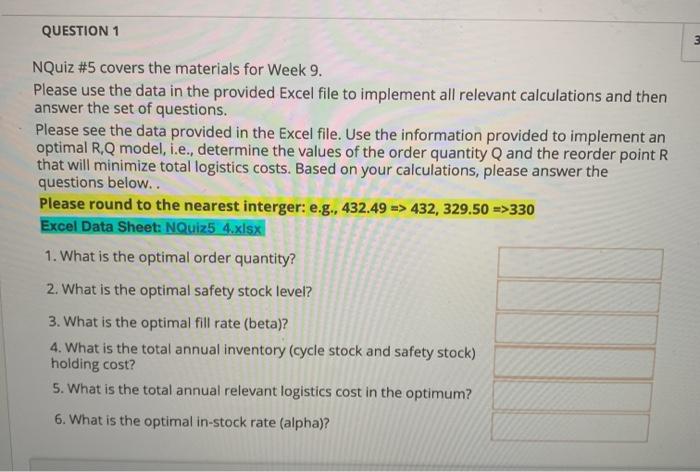

D B Notation D Op L O k H P C Value Measurement 8,860 units per year 2.040 units per year 0.1 years 0.04 years 24% per year per dollar of average Inventory 52.00 per unit 1248 per unit per year 9.20 per unit backordered 395.00 per order units units per load time 736.0 units per lead time The formula has already been entered $ $ $ $ 1 Parameter 2 Mean annual demand 3 Standard deviation of annual demand 4 Mean lead time 5 Standard deviation of lead time 6 Inventory holding cost factor (annual) 7 Unit purchase cost 8 Holding cost per unit per year 9 Backordering cost per unit 10 Ordering cost per order 11 Order quantity 12 Mean demand during the lead time 13 Standard deviation of demand during the lead time 14 Type 1 service level 15 Standard normal variate 16 Safety stock 17 Expected units out of stock during the load time 18 Type 2 service level 19 Reorder point 20 Annual Cycle Stock Holding Cost 21 Annual Safety Stock Holding Cont 22 Annual Ordering Cost 23 Annual Backordering Cost 24 Annual Total Relevant Logistics Cost 25 5 Q DL GOL alpha 2 SS nR beta R CSHC SSHC BC G(QR) units 293 units per cycle The formula has already been entered units per year per year per year per year per year QUESTION 1 NQuiz #5 covers the materials for Week 9. Please use the data in the provided Excel file to implement all relevant calculations and then answer the set of questions. Please see the data provided in the Excel file. Use the information provided to implement an optimal R.Q model, i.e., determine the values of the order quantity Q and the reorder point R that will minimize total logistics costs. Based on your calculations, please answer the questions below.. Please round to the nearest interger: e.g., 432.49 => 432, 329.50 =>330 Excel Data Sheet: NQuiz5 4.xlsx 1. What is the optimal order quantity? 2. What is the optimal safety stock level? 3. What is the optimal fill rate (beta)? 4. What is the total annual inventory (cycle stock and safety stock) holding cost? 5. What is the total annual relevant logistics cost in the optimum? 6. What is the optimal in-stock rate (alpha)? D B Notation D Op L O k H P C Value Measurement 8,860 units per year 2.040 units per year 0.1 years 0.04 years 24% per year per dollar of average Inventory 52.00 per unit 1248 per unit per year 9.20 per unit backordered 395.00 per order units units per load time 736.0 units per lead time The formula has already been entered $ $ $ $ 1 Parameter 2 Mean annual demand 3 Standard deviation of annual demand 4 Mean lead time 5 Standard deviation of lead time 6 Inventory holding cost factor (annual) 7 Unit purchase cost 8 Holding cost per unit per year 9 Backordering cost per unit 10 Ordering cost per order 11 Order quantity 12 Mean demand during the lead time 13 Standard deviation of demand during the lead time 14 Type 1 service level 15 Standard normal variate 16 Safety stock 17 Expected units out of stock during the load time 18 Type 2 service level 19 Reorder point 20 Annual Cycle Stock Holding Cost 21 Annual Safety Stock Holding Cont 22 Annual Ordering Cost 23 Annual Backordering Cost 24 Annual Total Relevant Logistics Cost 25 5 Q DL GOL alpha 2 SS nR beta R CSHC SSHC BC G(QR) units 293 units per cycle The formula has already been entered units per year per year per year per year per year QUESTION 1 NQuiz #5 covers the materials for Week 9. Please use the data in the provided Excel file to implement all relevant calculations and then answer the set of questions. Please see the data provided in the Excel file. Use the information provided to implement an optimal R.Q model, i.e., determine the values of the order quantity Q and the reorder point R that will minimize total logistics costs. Based on your calculations, please answer the questions below.. Please round to the nearest interger: e.g., 432.49 => 432, 329.50 =>330 Excel Data Sheet: NQuiz5 4.xlsx 1. What is the optimal order quantity? 2. What is the optimal safety stock level? 3. What is the optimal fill rate (beta)? 4. What is the total annual inventory (cycle stock and safety stock) holding cost? 5. What is the total annual relevant logistics cost in the optimum? 6. What is the optimal in-stock rate (alpha)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts