Question: ISE 2 3 6 0 Design for Manufacturing Lecture Assignment 9 Due date: Refer to the syllabus. 1 . Answer the following questions ( 4

ISE Design for Manufacturing

Lecture Assignment

Due date: Refer to the syllabus.

Answer the following questions pts :

What are the differences between the coolingsolidification of pure metals and metal alloys?

Sketch the internal structure of a sand mold draw the internal structure and label the name of each feature Explain the purpose of pouring basin, sprue, runner, and riser.

List three expendable mold processes. Explain how each process works.

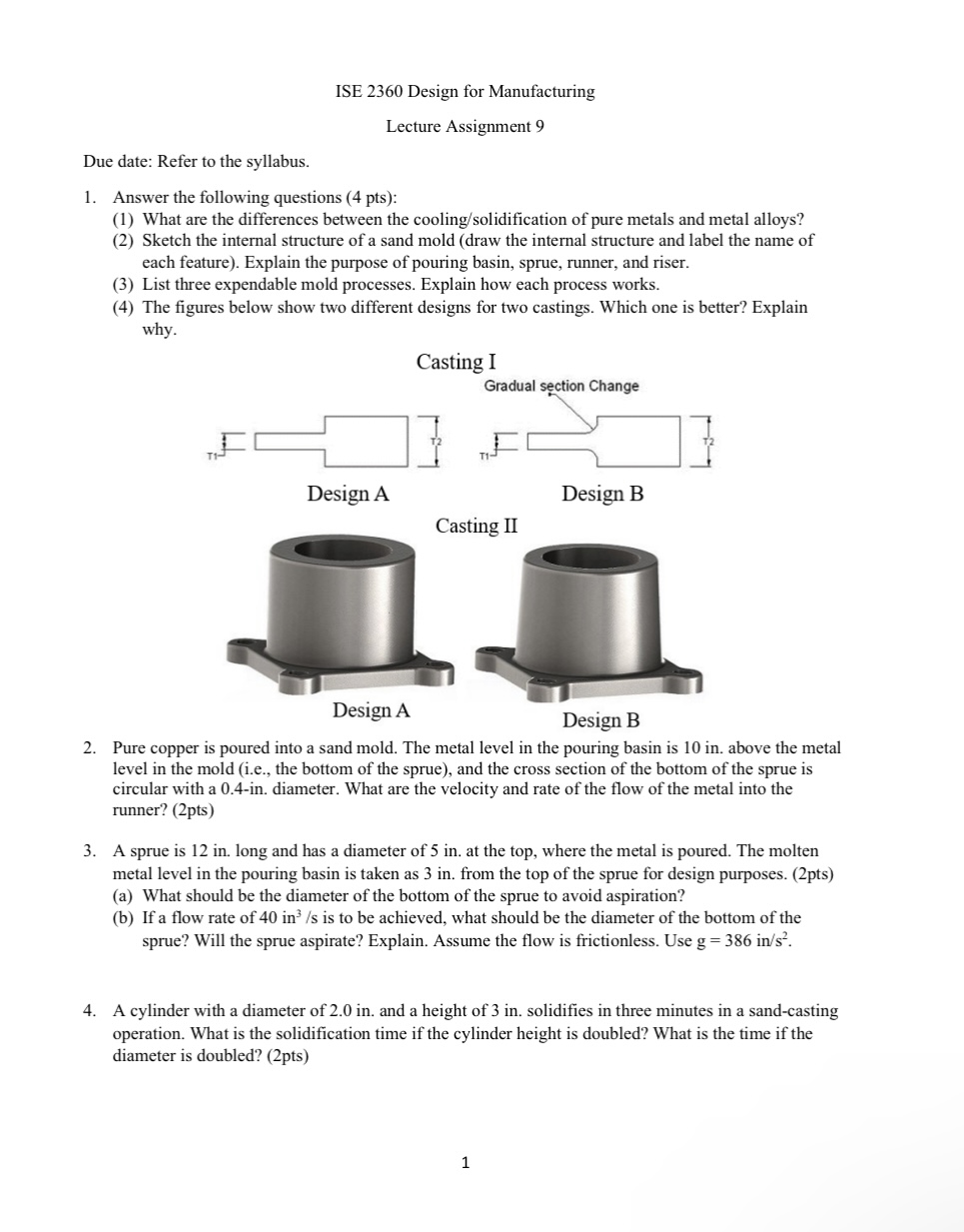

The figures below show two different designs for two castings. Which one is better? Explain why.

Pure copper is poured into a sand mold. The metal level in the pouring basin is in above the metal level in the mold ie the bottom of the sprue and the cross section of the bottom of the sprue is circular with a in diameter. What are the velocity and rate of the flow of the metal into the runner? pts

A sprue is in long and has a diameter of in at the top, where the metal is poured. The molten metal level in the pouring basin is taken as in from the top of the sprue for design purposes. pts

a What should be the diameter of the bottom of the sprue to avoid aspiration?

b If a flow rate of mathrminmathrms is to be achieved, what should be the diameter of the bottom of the sprue? Will the sprue aspirate? Explain. Assume the flow is frictionless. Use g mathrminmathrms

A cylinder with a diameter of in and a height of in solidifies in three minutes in a sandcasting operation. What is the solidification time if the cylinder height is doubled? What is the time if the diameter is doubled? pts

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock