Question: it cannot be clearer than this, pls try to zoom in Problem 9-15 One unit of A is made of two units of B and

it cannot be clearer than this, pls try to zoom in

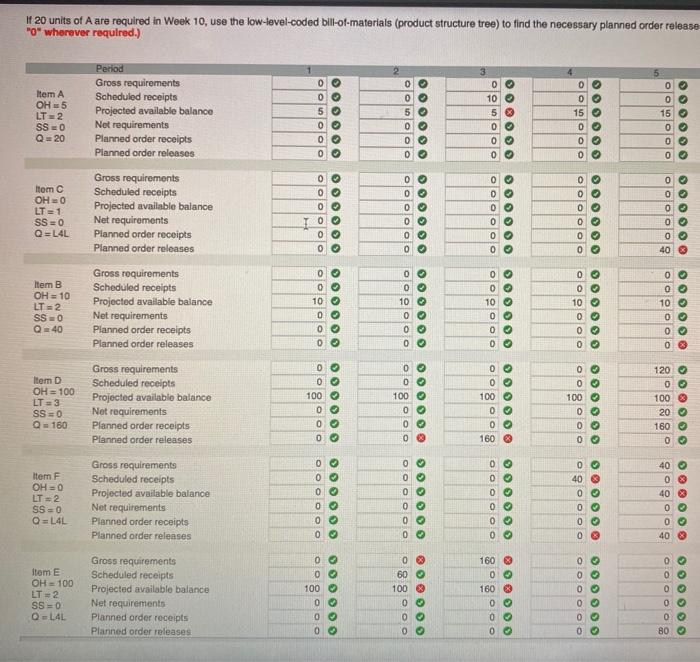

Problem 9-15 One unit of A is made of two units of B and one unit of C. B is made of three units of D and one unit of F. C is composed of three units of B, one unit of D, and four units of E. Dis made of one unit of E. Item C has a lead time of one week, Items A, B, E, and F have two-week lead times; and Item D has a lead time of three weeks. Lot-for-lot (L4L) lot sizing is used for Items C, E, and F; lots of size 20, 40, and 160 are used for Items A, B, and D, respectively. Items A, B, D, and E have on-hand (beginning) inventories of 5, 10, 100, and 100, respectively, all other items have zero beginning inventories. We are scheduled to receive 10 units of A in Week 3, 20 units of B in Week 7, 40 units of F in Week 5, and 60 units of E in Week 2; there are no other scheduled receipts. 1 20 units of A are required in Week 10, use the low-level-coded bill-of-materials (product structure tree) to find the necessary planned order release "0" wherever required.) 5 0 Item A OH 5 LT=2 SS=0 Q=20 0 10 5 ololololo OOOO OOOOO 0 15 OOOOOO 0 0 0 Period Gross requirements Scheduled receipts Projected available balance Net requirements Planned order receipts Planned order releases Gross requirements Scheduled receipts Projected available balance Net requirements Planned order receipts Planned order releases O 0 0 0 OOOOO OOO OOOOOO OOOOO OOOOOOOOOOO 0 O 0 0 0 Item C OH = 0 LT=1 SS=0 Q=L4L OOOOOO 0 0 0 OOOO 0 OOOO OOO OOO 0 Item B OH = 10 LT = 2 SS=0 Q.40 OOOOOO ODOBolo OOOOOO OOOOO 0 0 10 0 0 0 10 0 0 10 0 0 OOOOOO OOOOO 0 0 0 0 0 0 0 120 0 100 Gross requirements Scheduled receipts Projected available balance Net requirements Planned order receipts Planned order releases Gross requirements Scheduled receipts Projected availablo balance Net requirements Planned order receipts Planned order releases Gross requirements Scheduled receipts Projected available balance Net requirements Planned order receipts Planned order releases Item D OH = 100 LT=3 SS=0 Q160 100 0 100 0 0 0 0 0 100 0 0 0 100 20 160 0 BO OOOOO 0 0 0 160 0 0 40 0 Item F OH = 0 LT = 2 SS=0 O=L4L OOOOO 40 0 40 OOOOOO BOOOOO OOOO 0 0 0 0 40 Item E OH = 100 LT2 SS=0 OLAL Gross requirements Scheduled receipts Projected available balance Net requirements Planned order receipts Planned order releases 0 0 100 0 0 0 OOOOO 0 60 100 0 0 0 160 0 160 0 0 0 OOOOOO OOOOO 0 0 15 0 0 15 0 0 0 o ol 15 20 0 15 5 20 03 vel 10 0 0 15 0 0 0 0 0 0 0 20 0 0 20 0 0 0 o 0 0 0 oo 0 0 0 0 0 30 0 40 0 40 40 0 0 0 0 0 00 0 40 0 03 30 0 0 203 10 0 0 40 0 0 03 40 40 0 0 0 408 40 0 o 40 40 0 0 0 00 0 o 140 0 140 0 0 0 0 0 0 0 0 O 0 0. 0 0 o 0 oo 0 0 0 0 0 00 0 0 0 0 OO 0 40 0 00 40 40 oo OOOOOO 0 0 0 0 0 0. oo oo 0 0 0 00 oo 0 00 03 0 0 803 0. 10 80 80 0 0 0 0 0 0 0 0 0 One unit of A is made of two units of B and one unit of C. B is made of three units of D and one unit of F. C is composed of three units of B, one unit of D, and four units of E. D is made of one unit of E. Item C has a lead time of one week; Items A, B, E, and Fhave two-week lead times; and Item D has a lead time of three weeks. Lot-for-lot (L4L) lot sizing is used for Items C, E, and F: lots of size 20, 40, and 160 are used for Items A, B, and D. respectively. Items A, B, D, and E have on-hand (beginning) inventories of 5, 10, 100, and 100, respectively; all other items have zero beginning inventories. We are scheduled to receive 10 units of A in Week 3, 20 units of B in Week 7.40 units of F in Week 5, and 60 units of E in Week 2; there are no other scheduled receipts. If 20 units of A are required in Week 10, use the low-level-coded bill-of-materials (product structure tree) to find the necessary planned order releases for all components. (Leave no cells blank - be certain to enter "0" wherever required.) One unit of A is made of two units of B and one unit of C. B is made of three units of D and one unit of F. C is composed of three units of B, one unit of D, and four units of E. D is made of one unit of E. Item C has a lead time of one week; Items A B, E, and F have two-week lead times; and Item D has a lead time of three weeks. Lot-for-lot (L4L) lot sizing is used for Items C, E, and F; lots of size 20, 40, and 160 are used for Items A, B, and D, respectively. Items A, B, D, and E have on-hand (beginning) inventories of 5, 10, 100, and 100, respectively; all other items have zero beginning inventories. We are scheduled to receive 10 units of A in Week 3, 20 units of B in Week 7, 40 units of Fin Week 5, and 60 units of E in Week 2; there are no other scheduled receipts. If 20 units of A are required in Week 10, use the low-level-coded bill-of-materials (product structure tree) to find the necessary planned order releases for all components. (Leave no cells blank - be certain to enter "0" wherever required.)