Question: It would be great if you can solve the question fully, but if it is too long, please navigate me through how to approach this

It would be great if you can solve the question fully, but if it is too long, please navigate me through how to approach this question and some important factors. Thank you.

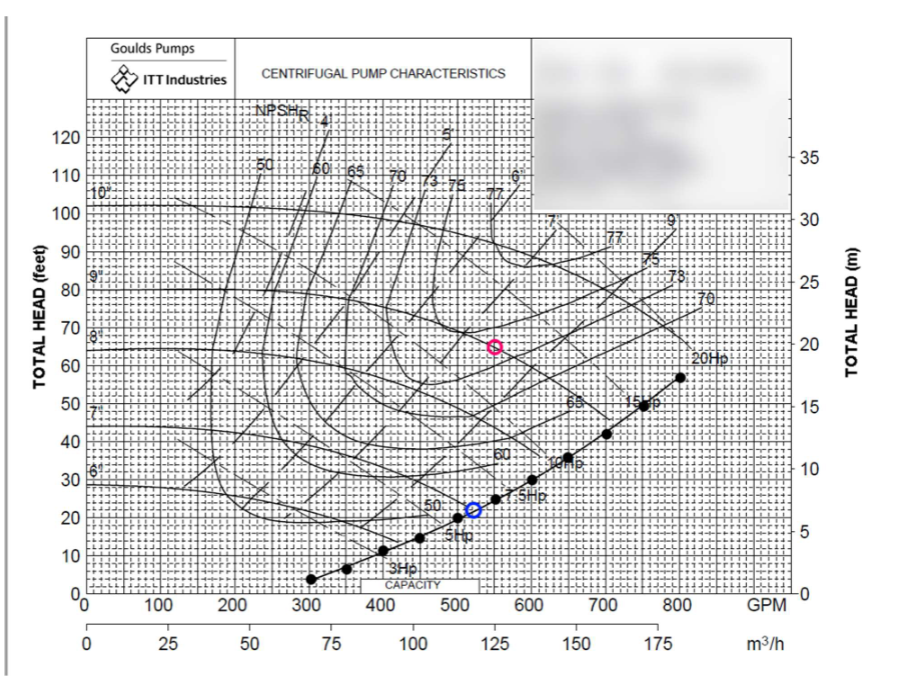

Water at 25 C is to be pumped as quickly as possible from a floodwater catch basin. The reservoir has an old pumping system in place, however, the pump has failed and must be replaced. It is hoped that a 3x4-10H Gould model pump that is on hand will suffice. The surface of the reservoir is 3.0 feet above the centerline of the old pump inlet. The pre-pump piping consists of 15 ft of 4 schedule- 40 cast iron pipe. There are several minor losses: a sharp-edge contraction (Kc = 0.4), three welded 90 elbows (Ke = 0.21 each) and a = ) a fully open globe valve (Kv = 6.0). There is 50 ft of straight-run (no fittings or valves) 3 schedule-40 cast iron pipe attached to the discharge side of the pump. = Estimate the maximum volume of flow rate (in GPM) that can be pumped without cavitation (assume that NPSHA should not exceed 95% of NPSHR). You will need to specify an impeller diameter, RPM (60 Hz), and motor horsepower. This will require a spreadsheet solution. I would suggest calculating the suction head, discharge head, and NPSHA for a series of flow rates over a range 200-750 GPM. Use the Churchill equation for calculation of friction factors. Print a copy of the 3x4-10H pump curve and plot the calculated data directly on the pump curve. I would use a paint program to modify the pump curve. Use this diagram to decide on the final operating parameters. Below is a pump curve/operating curve that shows a poorly chosen pump cannot really supply the capacity. Goulds Pumps ITT Industries CENTRIFUGAL PUMP CHARACTERISTICS NRSHA 120 -50 35 601-6$ 110 Fo? 100 30 77 90 78 80 25 TOTAL HEAD (feet) TOTAL HEAD (m) 70 8 20 20HP 60 50 15 40 10 30 20 5 10 3Hpl CAPACITY 400 500 -0 100 200 300 600 700 800 GPM 0 25 50 75 100 125 150 175 3/h

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts