Question: It's really hard to understand these questions. please help me step by step. 1. An allergy products superstore sells 400 of its most popular model

It's really hard to understand these questions. please help me step by step.

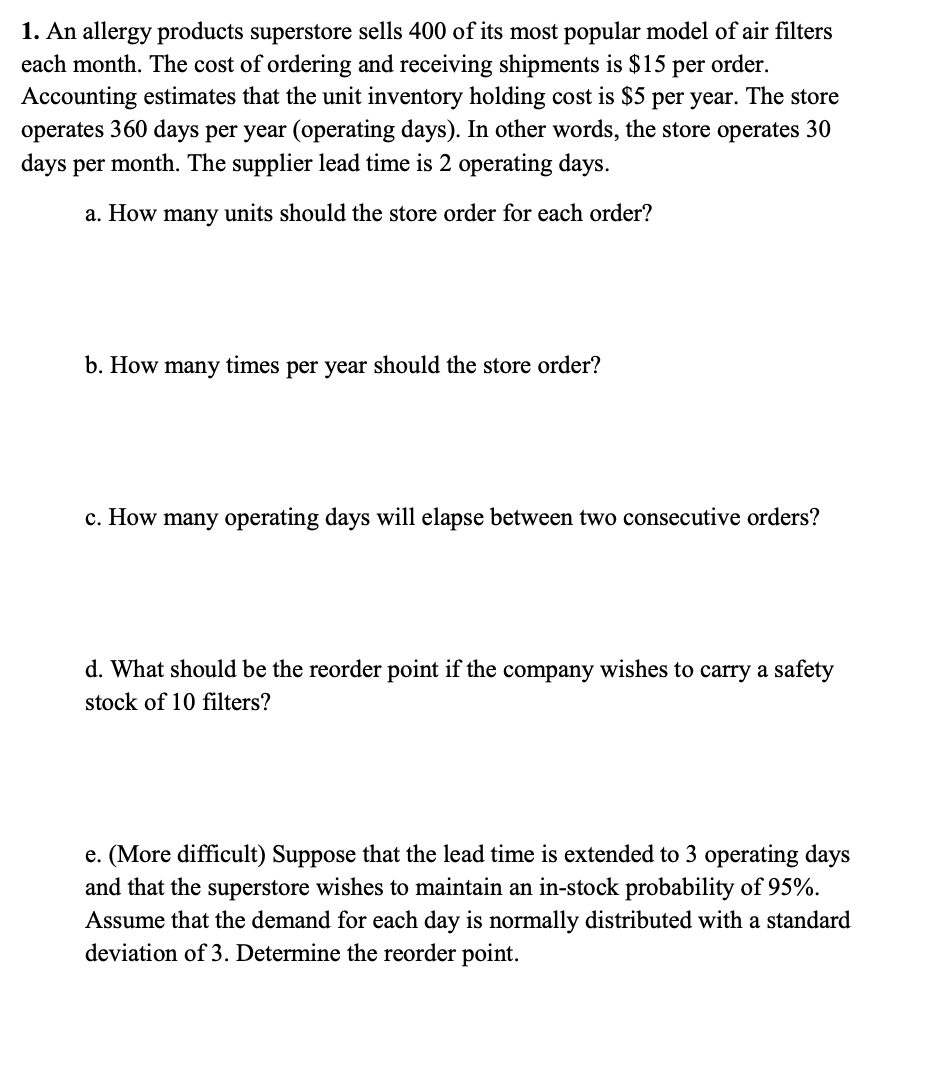

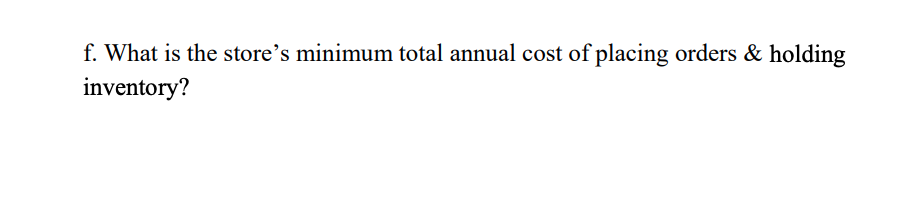

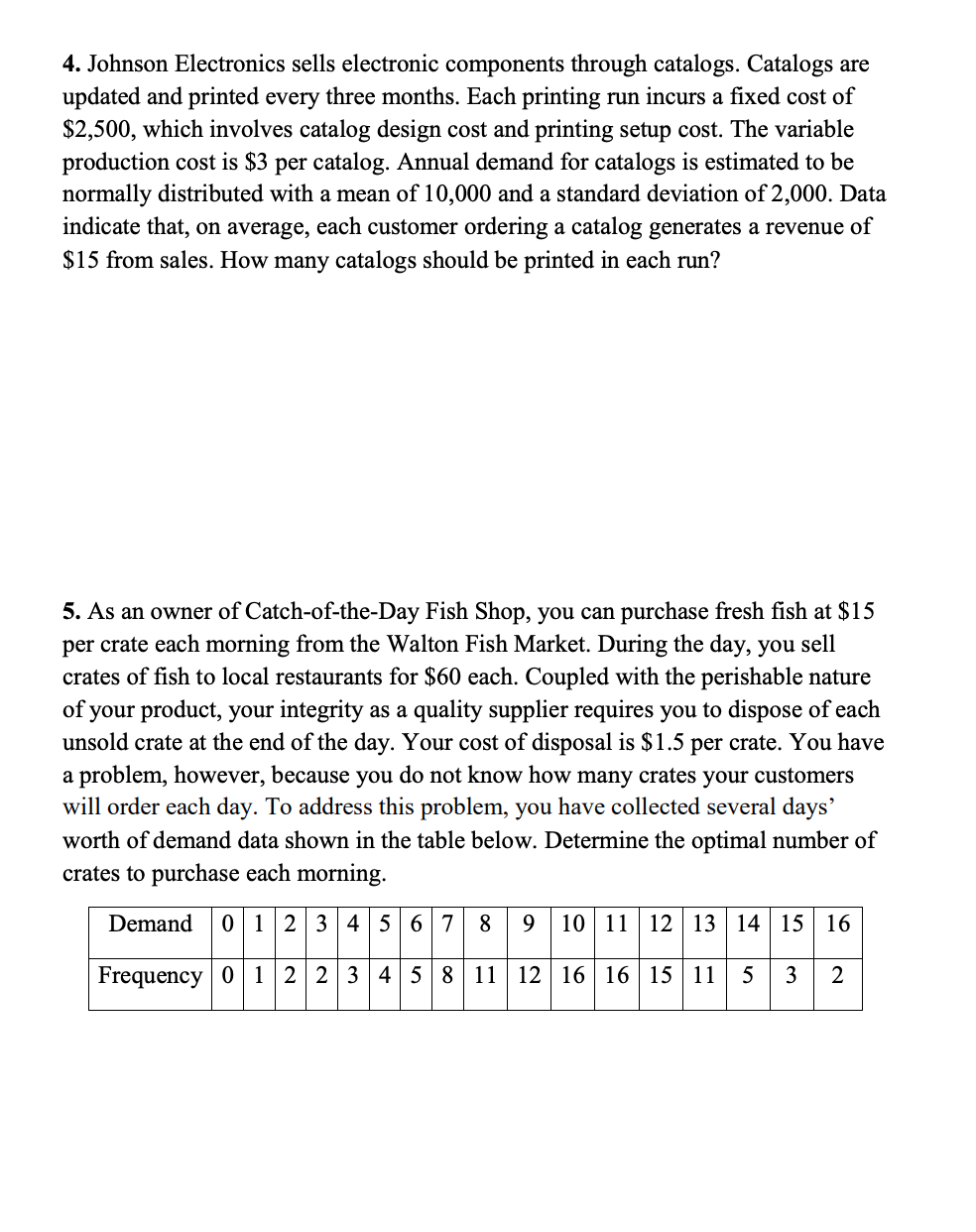

1. An allergy products superstore sells 400 of its most popular model of air filters each month. The cost of ordering and receiving shipments is $15 per order. Accounting estimates that the unit inventory holding cost is $5 per year. The store operates 360 days per year (operating days). In other words, the store operates 30 days per month. The supplier lead time is 2 operating days. a. How many units should the store order for each order? b. How many times per year should the store order? c. How many operating days will elapse between two consecutive orders? d. What should be the reorder point if the company wishes to carry a safety stock of 10 filters? e. (More difficult) Suppose that the lead time is extended to 3 operating days and that the superstore wishes to maintain an in-stock probability of 95%. Assume that the demand for each day is normally distributed with a standard deviation of 3. Determine the reorder point. f. What is the store's minimum total annual cost of placing orders \& holding inventory? 4. Johnson Electronics sells electronic components through catalogs. Catalogs are updated and printed every three months. Each printing run incurs a fixed cost of $2,500, which involves catalog design cost and printing setup cost. The variable production cost is $3 per catalog. Annual demand for catalogs is estimated to be normally distributed with a mean of 10,000 and a standard deviation of 2,000. Data indicate that, on average, each customer ordering a catalog generates a revenue of $15 from sales. How many catalogs should be printed in each run? 5. As an owner of Catch-of-the-Day Fish Shop, you can purchase fresh fish at $15 per crate each morning from the Walton Fish Market. During the day, you sell crates of fish to local restaurants for $60 each. Coupled with the perishable nature of your product, your integrity as a quality supplier requires you to dispose of each unsold crate at the end of the day. Your cost of disposal is $1.5 per crate. You have a problem, however, because you do not know how many crates your customers will order each day. To address this problem, you have collected several days' worth of demand data shown in the table below. Determine the optimal number of crates to purchase each morning. 3. Demands for a product during a lead time are in the table below. Use the data above to determine the amount of safety stock to achieve each of the following indicated service levels. a. 99% b. 95% c. 90% d. 80% e. 70%

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts