Question: iv . What seems to be the problem that limits the assembly system from achieving the expected production rate? ( 4 marks ) v .

iv What seems to be the problem that limits the assembly system from

achieving the expected production rate?

marks

v What is the production rate that the system is actually achieving? Include

any reasoning that you make in determining your answer.

marks

a The feed track for Station has a low level sensor located at component and

a high level sensor at component Once the high level sensor is activated the

selector automatically drops all components back into the hopper until the low

level sensor is activated.

How long will it actually take on average for the supply of parts to go from the low

level to the high level whilst ensuring that at no time the station is waiting on

components?

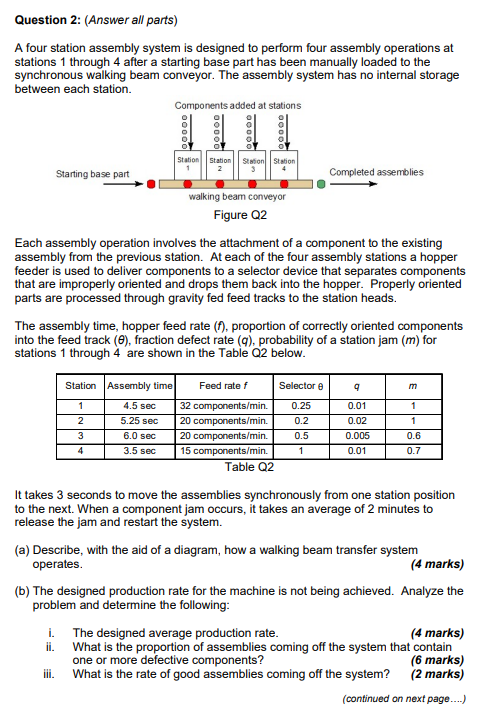

marksQuestion : Answer all parts

A four station assembly system is designed to perform four assembly operations at

stations through after a starting base part has been manually loaded to the

synchronous walking beam conveyor. The assembly system has no internal storage

between each station.

Each assembly operation involves the attachment of a component to the existing

assembly from the previous station. At each of the four assembly stations a hopper

feeder is used to deliver components to a selector device that separates components

that are improperly oriented and drops them back into the hopper. Properly oriented

parts are processed through gravity fed feed tracks to the station heads.

The assembly time, hopper feed rate proportion of correctly oriented components

into the feed track fraction defect rate probability of a station jam for

stations through are shown in the Table Q below.

Table Q

It takes seconds to move the assemblies synchronously from one station position

to the next. When a component jam occurs, it takes an average of minutes to

release the jam and restart the system.

a Describe, with the aid of a diagram, how a walking beam transfer system

operates.

marks

b The designed production rate for the machine is not being achieved. Analyze the

problem and determine the following:

i The designed average production rate.

marks

ii What is the proportion of assemblies coming off the system that contain

one or more defective components?

marks

iii. What is the rate of good assemblies coming off the system?

marks

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock